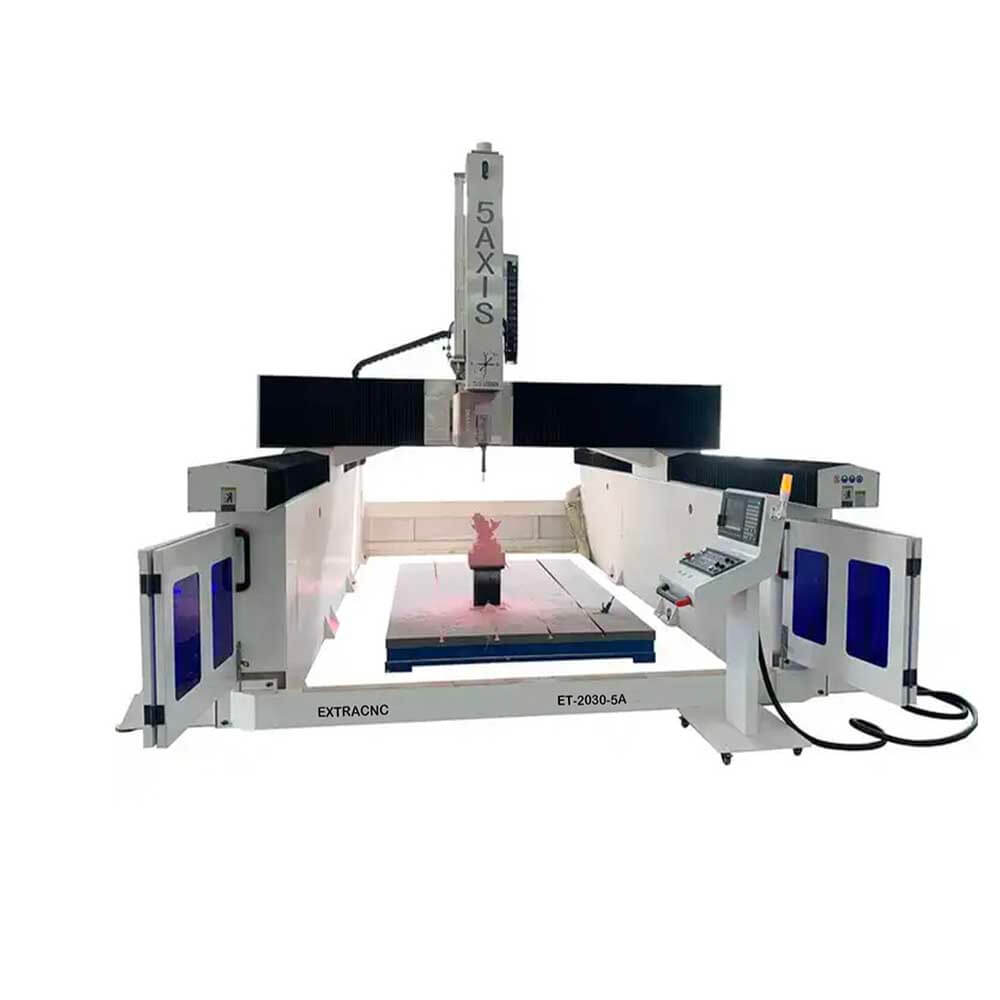

1. Advanced Closed-Loop Control System

Powered by Oriental Motor’s alphaStep closed-loop technology, our 5 axis CNC router ensures real-time position feedback on all axes—eliminating position errors and delivering unmatched accuracy in woodworking and mold making.

2. Low-Backlash Gear Transmission

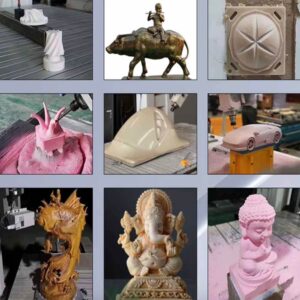

Each axis uses tapered-hob gear heads with minimal backlash, maintaining consistent torque and high-speed performance. Ideal for precision CNC wood carving and complex 3D shapes.

3. Precision Linear Guides & Bearings

All axes are supported by high-precision linear rails, ensuring smooth, accurate motion, essential for detailed 5 axis CNC milling and intricate wood machining tasks.

4. Rack-and-Pinion Drive System

The rack-and-pinion mechanism offers strong, reliable, and easy-to-maintain motion control—perfect for continuous operation in woodworking shops and factories.

5. High-Speed Cutting Performance

Achieve cutting speeds up to 360 in/min and rapid traverse speeds of 1,200 in/min, depending on tool and material. Boost your workshop efficiency with high-speed 5 axis CNC routing.

6. High Accuracy & Repeatability

With a cutting tolerance of ±0.03”, this machine is ideal for precision wood mold making, 3D carving, and complex surface machining.

7. Industrial-Grade Electrical Cabinet

Includes a sealed, UL-certified control box for safe, durable operation in demanding production environments.

8. Built-In Safety Features

Comes standard with emergency stop, spindle interlock, and limit switches on X, Y, Z, A, and B axes, ensuring safe, controlled machining at all times.

9. Z-Zero Touch-Off and Tool Calibration

Includes a Z-zero touch-off plate for fast, accurate tool length setup—saving time and reducing human error.

10. Fully Assembled with Lifetime Support

Ships fully assembled and includes lifetime technical support, free phone consultation, detailed online documentation, and a 2-year warranty.