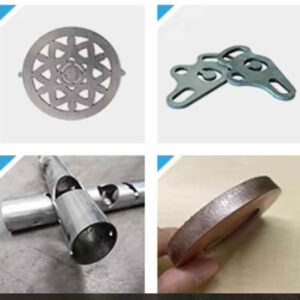

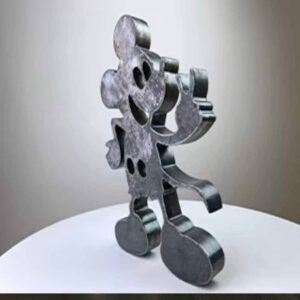

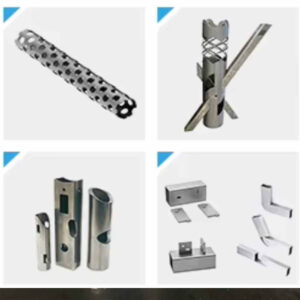

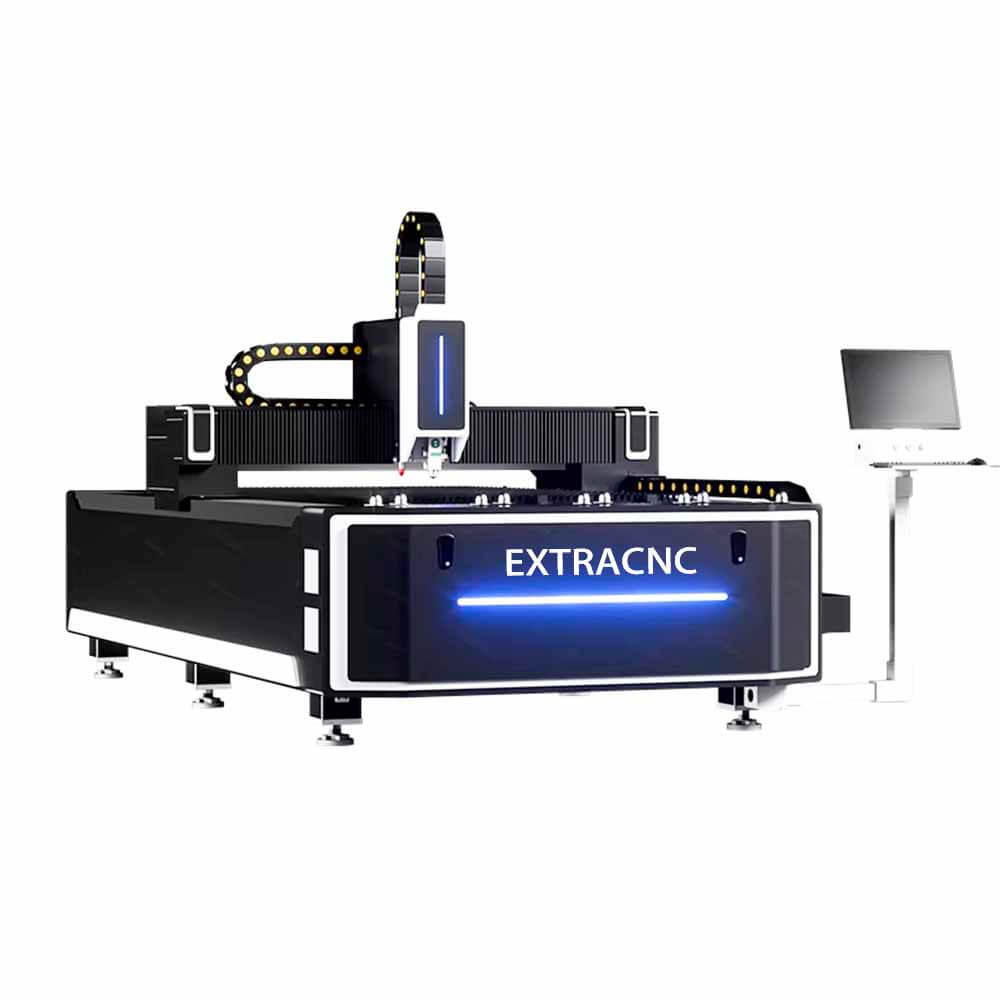

The Волоконный лазерный станок для резки металла для плоской и трубчатой стали широко используется в изготовление металлоконструкций, вывесок, автомобилестроение, аэрокосмическая промышленность, кухонные принадлежности, строительство и изготовление металлоконструкций на заказ. Он эффективно режет нержавеющая сталь, углеродистая сталь, алюминий, латунь, медь и другие металлы, что делает его идеальным для обработка листового металла, резка труб, промышленные компоненты, декоративное искусство металла и точное производство.