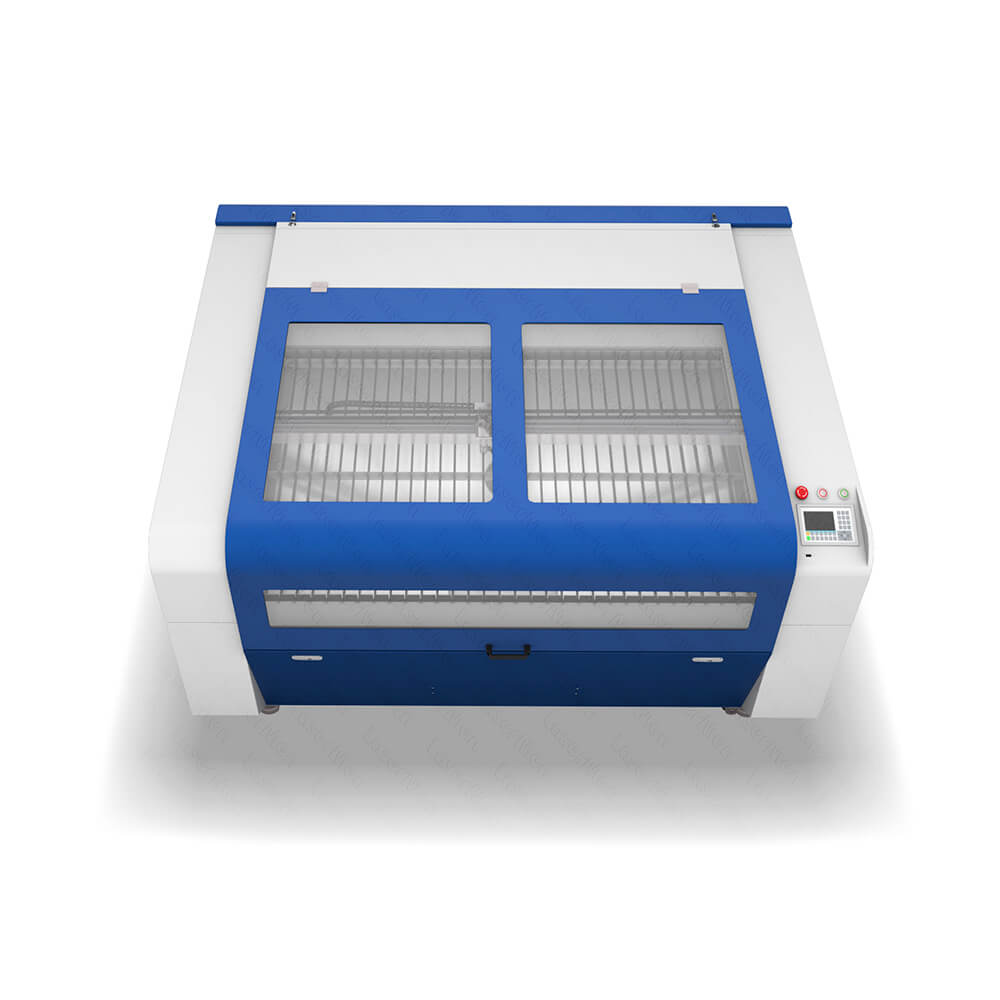

Станок для лазерной резки CO2

А Станок для лазерной резки CO2 — это мощный и точный инструмент, который использует лазерный луч CO2 для резки, гравировки и маркировки различных материалов, включая дерево, акрил, пластик, стекло и текстиль. Технология лазера CO2 генерирует мощный лазерный луч, который можно сфокусировать на небольшой точке, создавая чистые, четкие разрезы с минимальным тепловым искажением. Эти машины широко используются в таких отраслях, как производство вывесок, упаковки и декоративных изделий, где требуются сложные конструкции и быстрая, эффективная обработка. Станки для лазерной резки CO2 особенно эффективны для неметаллических материалов и известны своей способностью производить высококачественную отделку. Благодаря передовому программному управлению они предлагают простое программирование, точность и скорость, что делает их идеальными как для мелкосерийного, так и для крупносерийного производства. Возможность работать с широким спектром материалов и обеспечивать исключительную точность делает станки для лазерной резки CO2 бесценными в современных производственных процессах.

Станок для лазерной резки CO2: точность и универсальность для современного производства

The Станок для лазерной резки CO2 это передовая технология, которая использует лазер на углекислом газе для резки широкого спектра материалов, включая металлы, пластмассы, древесина, и акрил. Известный своей высокой точностью, скоростью и универсальностью, Станок для лазерной резки CO2 широко используется в различных отраслях промышленности, таких как изготовление знаков, изготовление металла, автомобильный, аэрокосмическая промышленность, и производство мебели. В этой статье рассматриваются функциональные возможности, области применения и преимущества Станки для лазерной резки CO2, что делает его ценным ресурсом для предприятий, стремящихся оптимизировать свои процессы резки.

Кто использует станок для резки лазером CO2?

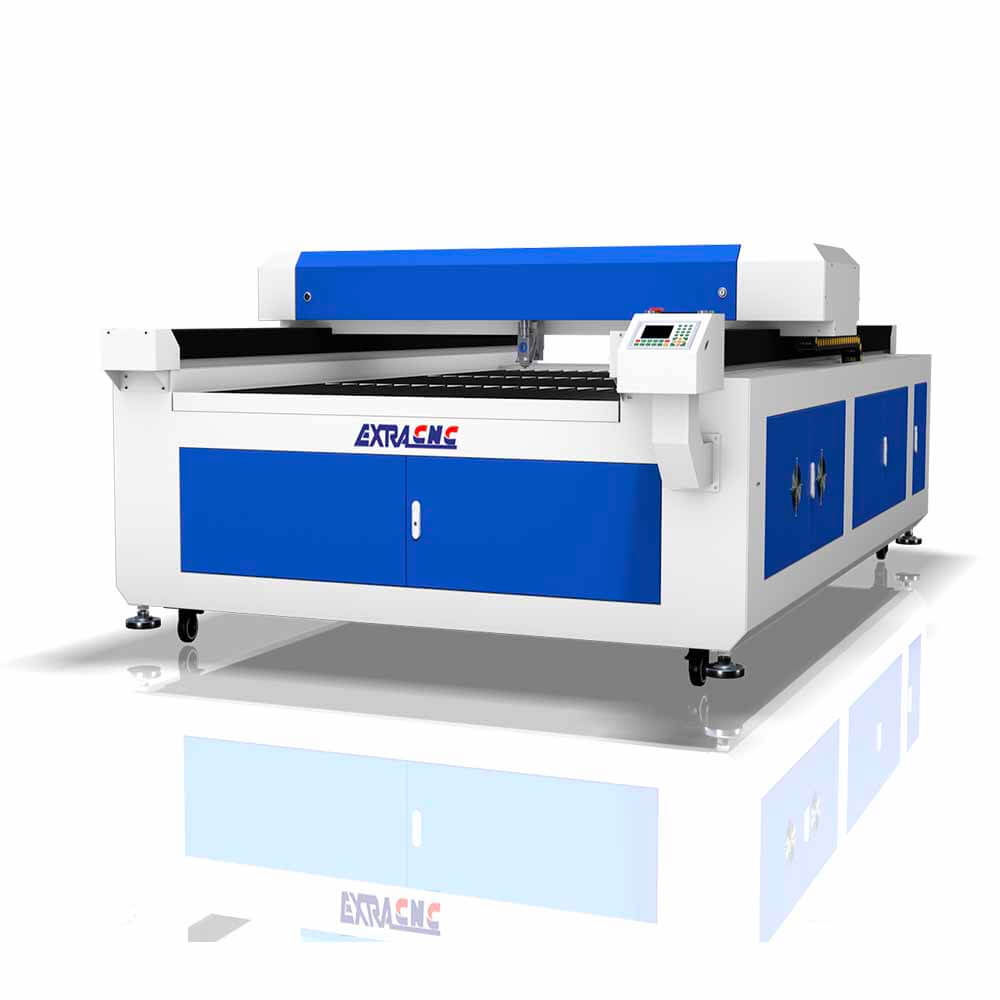

The Станок для лазерной резки CO2 используется в отраслях, где требуется сложная и высокоточная резка. Некоторые из основных секторов включают:

Изготовление металлоконструкций: Для резки тонких листов нержавеющая сталь, алюминий, латунь, и углеродистая сталь.

Изготовление вывесок и рекламы: Для резки и гравировки акрил, пластик, и древесина материалы для создания индивидуальных знаков, логотипов и дисплеев.

Производство мебели: Для резки дерева и акриловых материалов для изготовления деталей мебели и декора.

Автомобильная и аэрокосмическая промышленность: Для точной резки металлических деталей и компонентов для транспортных средств и самолетов.

Искусство и скульптура: Для создания сложных конструкций и скульптур из различных материалов, включая дерево, металл и акрил.

Что такое станок для резки лазером CO2?

А Станок для лазерной резки CO2 это машина, которая использует CO2-лазер для резки или гравировки материалов. CO2-лазер это тип газового лазера, в котором смесь углекислого газа, азота и водорода возбуждается электрическим током, создавая мощный лазерный луч, направленный на материал. Этот лазерный луч может резать материалы, плавя, сжигая или испаряя их с высокой точностью.

Эти машины оснащены ЧПУ (числовое программное управление) системы, которые обеспечивают точное перемещение и позиционирование лазерной головки по нескольким осям (обычно X, Y и Z). CO2 лазерные резаки высокоэффективны для резки материалов тонкой и средней толщины и используются там, где требуются чистые, точные разрезы и сложные конструкции.

Где используются станки для резки лазером CO2?

Станки для лазерной резки CO2 используются в самых разных областях и отраслях, включая:

Изготовление и гравировка вывесок: Гравировка и резка логотипов, вывесок и индивидуальных дизайнов на акрил, древесина, и пластик материалы.

Изготовление металлоконструкций: Резка тонкие металлические листы для деталей и компонентов в таких отраслях, как автомобилестроение, аэрокосмическая промышленность и электроника.

Текстильная промышленность: Раскрой тканей и текстильных изделий для модной одежды, домашнего декора и индивидуального пошива одежды.

Производство мебели: Резка древесина, МДФ, и акрил материалы для индивидуального проектирования мебели.

Искусство и дизайн: Создание сложных произведений искусства и скульптур из древесина, акрил, и металл.

Когда станки для лазерной резки CO2 приобрели популярность?

Технология резки лазером CO2 существует с 1960-х годов, но широкое распространение он начал получать в 1980-х годах, когда промышленность начала искать более эффективные и точные методы резки материалов. Универсальность Станки для лазерной резки CO2, особенно их способность резать различные материалы, такие как древесина, пластмассы, и металл, сделали их привлекательным выбором для многих отраслей промышленности. За эти годы достижения в Системы управления ЧПУ и мощность лазера только повысили эффективность и точность этих машин.

Почему так важны станки для резки лазером CO2?

Высокая точность и достоверность: Возможность делать точные разрезы и сложные конструкции делает Станки для лазерной резки CO2 необходим для отраслей, где детализация и точность имеют первостепенное значение. Будь то для гравировка, изготовление знаков, или изготовление металлаЭти машины обеспечивают чистые, четкие разрезы с минимальными отходами материала.

Универсальность в отношении материалов: CO2-лазеры невероятно универсальны и могут резать и гравировать широкий спектр материалов, включая древесина, акрил, пластик, резина, и металл. Такая гибкость делает их подходящими для отраслей с разнообразными производственными потребностями.

Скорость и эффективность: Станки для лазерной резки CO2 предлагают высокие скорости резки, позволяя предприятиям увеличить производительность и соблюдать жесткие сроки. Технология также снижает потребность во вторичных процессах, таких как сверление, что может сэкономить время и деньги.

Экономически эффективное производство: За счет снижения необходимости дополнительных этапов обработки и минимизации отходов материала, резка лазером CO2 является эффективным и экономичным решением для производства. Возможность достижения высокой точности без чрезмерного труда или дополнительных затрат делает Станки для лазерной резки CO2 идеальный выбор для многих предприятий.

Низкие эксплуатационные расходы и простота эксплуатации: В отличие от традиционных методов резки, которые могут требовать постоянного обслуживания, Станки для лазерной резки CO2 относительно низкие эксплуатационные расходы. Системы управления ЧПУ также упрощают эксплуатацию, снижая потребность в квалифицированной рабочей силе и повышая общую производительность.

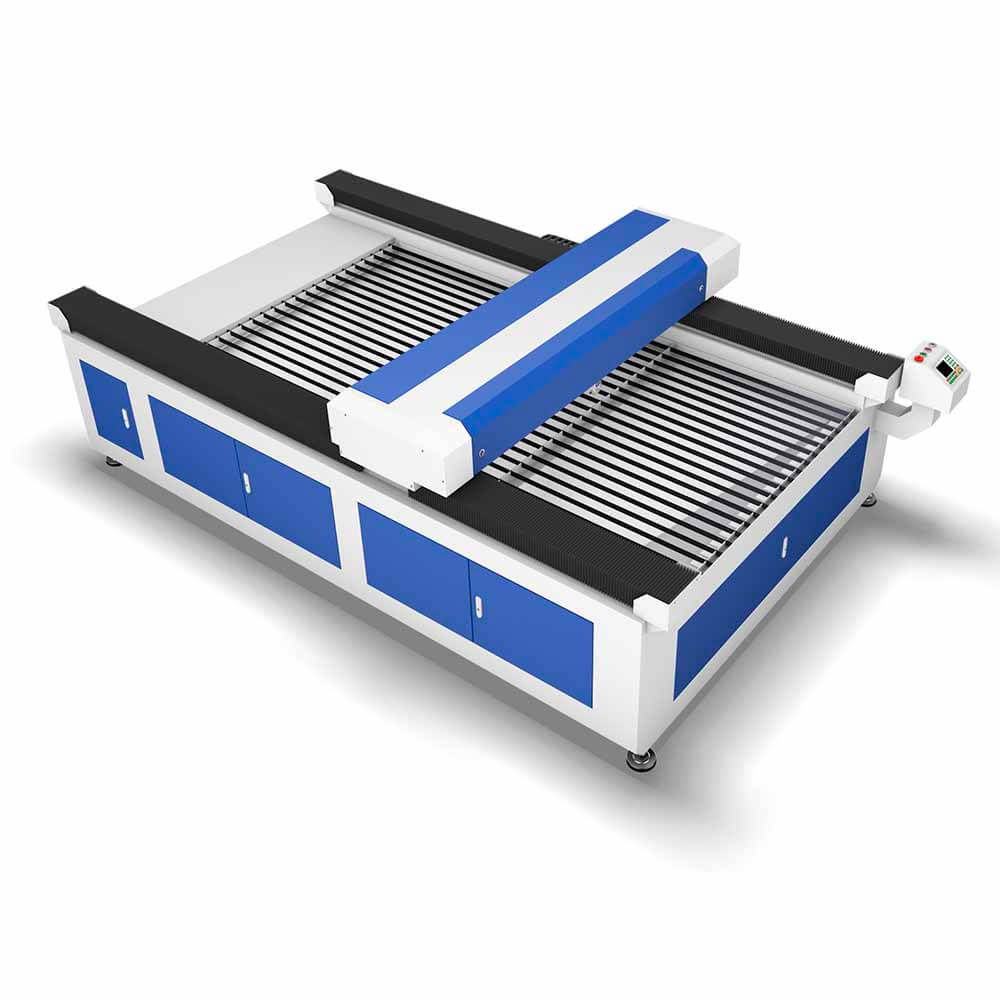

Как работает станок для резки лазером CO2?

Фаза проектирования: Процесс начинается с проектирования, часто создаваемого с использованием САПР (система автоматизированного проектирования) программное обеспечение. После завершения разработки дизайн отправляется CAM (компьютеризированное производство) программное обеспечение, которое генерирует инструкции по резке для машины.

Настройка материала: Материал помещается на режущую платформу машины. система ЧПУ обеспечивает правильное выравнивание материала для точной резки.

Лазерная резка: Луч CO2-лазера фокусируется на материале, где он нагревается и прорезает материал, испаряя, расплавляя или сжигая его. Машина перемещает лазерную головку по заранее запрограммированным траекториям с предельной точностью, следуя дизайну.

Постобработка: После того, как материал нарезан, он может пройти дополнительные процессы, такие как гравировка, удаление заусенцев, или полировка для обеспечения соответствия конечного продукта требуемым стандартам качества.

Преимущества использования станка для лазерной резки CO2

Точность и чистота реза: Одна из выдающихся особенностей Станки для лазерной резки CO2 является их способность делать чистые, точные разрезы с минимальными отходами материала. Высокая точность позволяет производителям создавать сложные конструкции с острыми краями.

Возможность резки различных материалов: Работаете ли вы с металл, древесина, пластмассы, или акрил, Станок для лазерной резки CO2 может обрабатывать широкий спектр материалов, что делает его чрезвычайно универсальным инструментом.

Высокая скорость работы: CO2 лазерные резаки работают на высоких скоростях, повышая эффективность производства и сокращая время выполнения заказов, что имеет решающее значение для отраслей с большими объемами производства.

Сокращение отходов: процесс лазерной резки отличается высокой эффективностью, что приводит к минимальным отходам материала, что приводит к экономии средств и повышению экологичности производственного процесса.

Индивидуализация и гибкость: Способность гравировать или резать сложные конструкции делают резка лазером CO2 идеально подходит для индивидуальной работы, от персонализированных вывески запутанный произведения искусства и мебель конструкции.

Низкие эксплуатационные расходы: Высокая эффективность, минимальные трудозатраты и низкие потребности в обслуживании способствуют снижению эксплуатационных расходов, обеспечивая привлекательную окупаемость инвестиций для предприятий.

Заключение

The Станок для лазерной резки CO2 мощный инструмент, который сочетает в себе точность, скорость и универсальность для широкого спектра задач резки и гравировки. Независимо от того, находитесь ли вы в индустрия изготовления вывесок, изготовление металла, или производство мебели, эта машина обеспечивает исключительную ценность за счет повышения производительности, сокращения отходов и обеспечения высококачественных результатов. Используя Технология лазера CO2предприятия могут добиться превосходной производительности при одновременном снижении затрат, что делает это разумной инвестицией в современные производственные потребности.