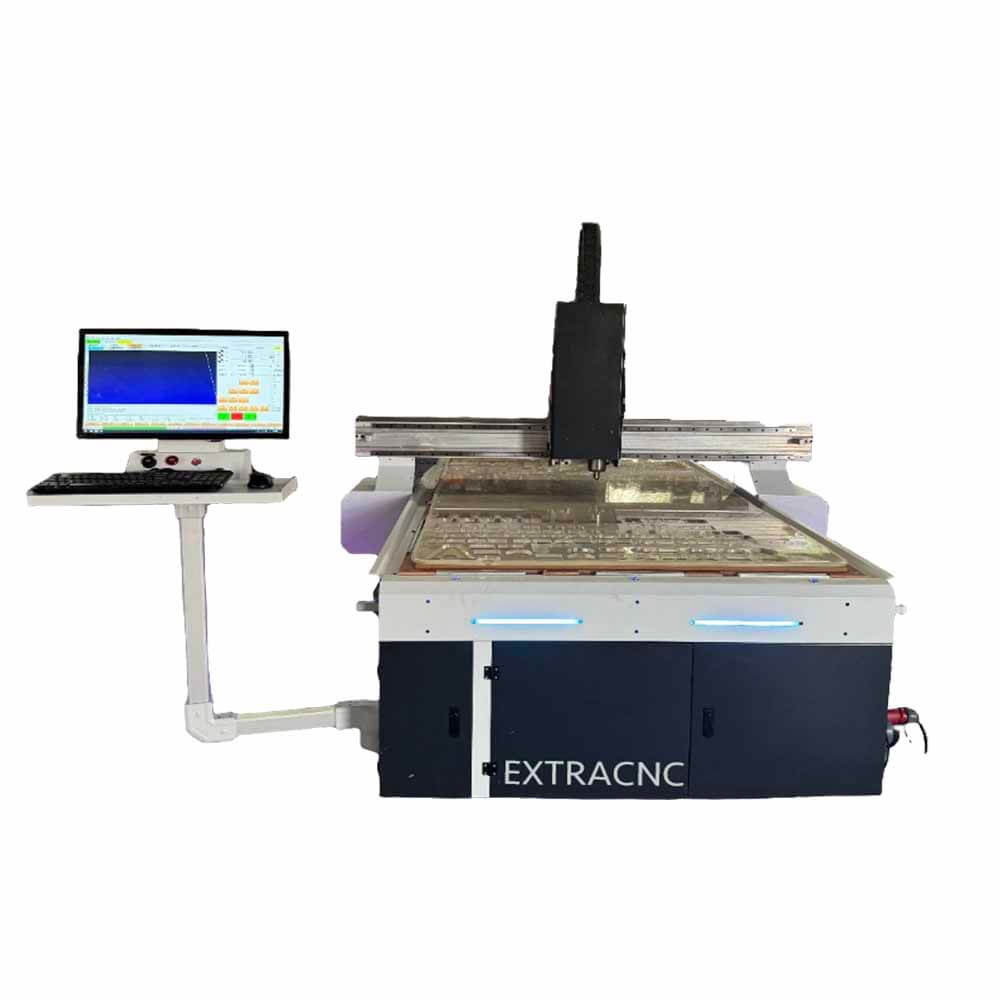

Фрезерный станок с ЧПУ по дереву

Фрезерный станок с ЧПУ по дереву — это современный станок с компьютерным управлением, который произвел революцию в обработке древесины, используя передовые технологии CAD/CAM для точной резки, резки и гравировки широкого спектра древесных материалов — идеально подходит для производства мебели, архитектурного дизайна и изготовления шкафов на заказ. Кому это выгодно? Профессиональным плотникам, дизайнерам и производителям по всему миру, которым нужна эффективность и превосходная точность. Что это? Это автоматизированный фрезерный станок, который объединяет несколько осей для создания гладких и сложных конструкций, которые невозможно получить традиционными ручными методами. Где он используется? В высокотехнологичных мастерских, на промышленных производственных линиях и в мастерских ремесленников, где качество и повторяемость имеют первостепенное значение. Когда он применяется? На протяжении всех современных производственных циклов — от разработки прототипа до крупносерийного производства — обеспечивая неизменное мастерство каждый раз. Почему это важно? Потому что он оптимизирует производство, минимизирует отходы и повышает качество продукции за счет снижения человеческих ошибок и выполнения точных, детальных разрезов древесины. Как это работает? Интерпретируя цифровые чертежи с помощью сложного программного интерфейса, фрезерный станок с ЧПУ по дереву следует запрограммированным траекториям инструмента для выполнения одновременных многоосевых движений, превращая необработанную древесину в точно детализированные, изготовленные на заказ изделия, соответствующие строгим отраслевым стандартам.

Фрезерный станок с ЧПУ по дереву — это современный фрезерный станок с числовым программным управлением (ЧПУ), который изменил сферу цифрового производства древесины. Этот инновационный деревообрабатывающий станок сочетает в себе передовые технологии CAD/CAM с высокоточным управлением движением для получения исключительных результатов в области изготовления корпусной мебели с ЧПУ, резьбы по дереву, изготовления мебели на заказ и фрезерования с ЧПУ. Благодаря бесшовной интеграции цифрового проектирования с автоматизированным удалением материала этот станок обеспечивает точную гравировку и создание сложных узоров, что позволяет современным производителям и ремесленникам достигать исключительного качества и эффективности.

Кто использует фрезерный станок по дереву с ЧПУ?

Профессиональные столяры, мебельщики, производители мебели, изготовители вывесок и преданные своему делу энтузиасты полагаются на фрезерные станки с ЧПУ для дерева, чтобы добиться стабильных, высококачественных результатов. В частности, отрасли, которые фокусируются на изготовлении мебели с ЧПУ и изготовлении мебели на заказ, выигрывают от точности и повторяемости, предлагаемых этими системами.

Что такое фрезерный станок по дереву с ЧПУ?

Фрезерный станок с ЧПУ по дереву — это передовое, управляемое компьютером режущее устройство, разработанное для сложных операций, таких как резьба по дереву, фрезерование с ЧПУ и точная гравировка. Преобразуя подробные цифровые чертежи в точные траектории инструментов, этот станок автоматизирует процесс формовки, резьбы и фрезерования древесины с необычайной точностью. Интегрированный контроллер ЧПУ управляет движениями по нескольким осям (обычно X, Y и Z), что позволяет производить сложные объекты, такие разнообразные, как декоративные панели, компоненты шкафов и художественная резьба по дереву.

Где это используется?

Фрезерные станки с ЧПУ по дереву используются в широком диапазоне условий, включая промышленные производственные цеха, специализированные деревообрабатывающие цеха и домашние мастерские. Они играют ключевую роль в:

Промышленное деревообрабатывающее производство: массовое производство шкафов, мебели и предметов интерьера.

Изготовление мебели на заказ: создание индивидуальных изделий с детальной резьбой по дереву и точной гравировкой.

Изготовление вывесок и декоративных изделий: вырезание сложных узоров и логотипов для коммерческих вывесок.

Образовательные и прототипные лаборатории: где передовые методы цифрового производства оптимизируют эксперименты и мелкосерийное производство.

Когда фрезерные станки с ЧПУ по дереву стали незаменимыми?

Быстрое развитие цифровых технологий производства и автоматизации в конце 20-го века стало катализатором широкого внедрения ЧПУ-фрезерных станков по дереву. Поскольку спрос на инновационные разработки в производстве мебели на заказ и производстве шкафов с ЧПУ резко возрос, эти станки быстро стали незаменимыми для производителей и мастеров, стремящихся как к большим объемам производства, так и к детальным проектам резьбы по дереву.

Почему важен фрезерный станок с ЧПУ по дереву?

Повышенная точность и повторяемость: способность фрезерного станка с ЧПУ последовательно выполнять предварительно запрограммированные траектории движения инструмента значительно снижает вероятность человеческих ошибок, что делает его идеальным для операций фрезерования с ЧПУ, резьбы по дереву и точной гравировки.

Повышение эффективности и производительности: автоматизация позволяет сократить производственные циклы, свести к минимуму ручное вмешательство и сократить время наладки — ключевые преимущества при изготовлении мебели на заказ и крупносерийном производстве шкафов на станках с ЧПУ.

Универсальное применение: этот современный деревообрабатывающий станок подходит для широкого спектра проектов: от художественных разработок до точных промышленных компонентов, будь то изготовление тонких изгибов, необходимых при резьбе по дереву, или линейных разрезов на фрезерном станке с ЧПУ.

Экономическая эффективность: оптимизируя производственный процесс и сокращая отходы материалов, фрезерные станки с ЧПУ обеспечивают высокую окупаемость инвестиций, что делает их популярным выбором как в коммерческих, так и в любительских областях цифрового производства.

Как работает фрезерный станок по дереву с ЧПУ?

Этап проектирования: Детальные проекты разрабатываются с использованием программного обеспечения САПР, создавая сложные конструкции — будь то предмет мебели, резная вывеска или изготовленная на заказ мебель.

Программирование CAM: проект CAD импортируется в программное обеспечение CAM, которое преобразует проект в ряд траекторий инструмента, выраженных в виде G-кода или M-кода. Этот код определяет точные движения по осям X, Y и Z для процесса фрезерования с ЧПУ.

Установка заготовки: Деревянный материал закрепляется на вакуумном столе или верстаке с Т-образными пазами, что обеспечивает устойчивость во время высокоточных операций резки, резьбы или гравировки.

Процесс обработки: управляемый встроенным контроллером ЧПУ, шпиндель станка систематически движется вдоль нескольких осей. Это скоординированное движение облегчает как резьбу по дереву, так и точную гравировку, производя чистые, детальные разрезы, которые соответствуют строгим стандартам качества.

Финишные операции: После первичной обработки может применяться последующая обработка, такая как шлифование, снятие заусенцев или герметизация, для придания заготовке безупречного вида.