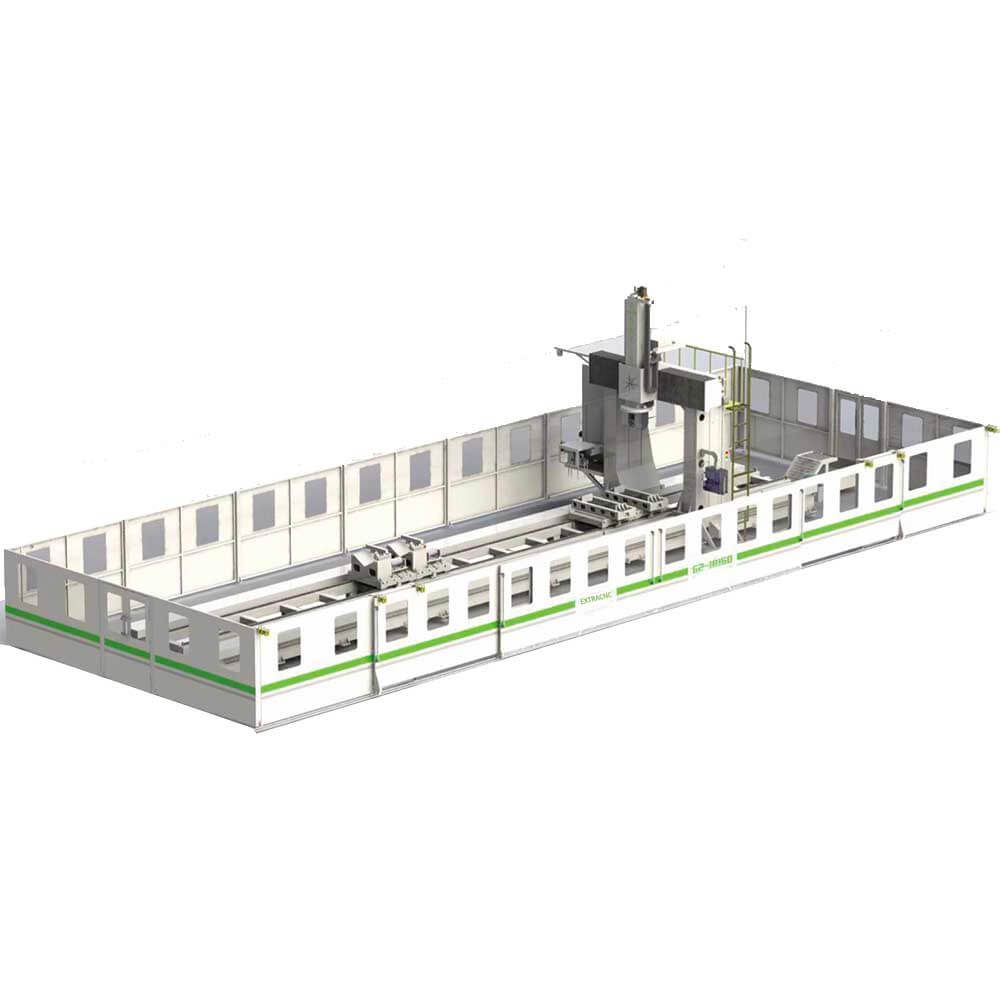

3D фрезерный станок с ЧПУ

ChatGPT сказал:

А 3D фрезерный станок с ЧПУ — это усовершенствованный, управляемый компьютером обрабатывающий инструмент, предназначенный для вырезания, фрезерования и формования сложных трехмерных объектов с высокой точностью из таких материалов, как дерево, пенопласт, пластик, МДФ и цветные металлы. Широко используемый в таких отраслях, как деревообработка, изготовление пресс-форм, изготовление мебели на заказ, вывесок и скульптуры, этот универсальный станок преобразует цифровые проекты в физические продукты с исключительной точностью и эффективностью. Автоматизируя производство подробных трехмерных форм, 3D-фрезерный станок с ЧПУ повышает производительность, сокращает отходы материала и обеспечивает безупречные результаты, что делает его незаменимым решением для предприятий и дизайнеров, стремящихся к высококачественному мастерству и быстрым срокам выполнения работ.

А 3D фрезерный станок с ЧПУ — это передовой, управляемый компьютером обрабатывающий инструмент, специально разработанный для производства сложных трехмерных форм с исключительной точностью и эффективностью. Это передовое оборудование стало неотъемлемой частью современного производства, деревообработки, прототипирования, изготовления форм и художественных отраслей, позволяя компаниям быстро и точно превращать сложные цифровые проекты в физические продукты.

Кто использует 3D-фрезерный станок с ЧПУ?

3D фрезерные станки с ЧПУ широко используются в таких отраслях, как изготовление мебели на заказ, изготовление пресс-форм, производство вывесок, мастерские резьбы по дереву, изготовление прототипов из металла, архитектурное моделирование и студии креативной скульптурыНезависимо от того, являетесь ли вы крупным производителем или независимым проектировщиком, 3D-фрезерный станок с ЧПУ позволяет вам эффективно преобразовывать цифровые модели в безупречные физические компоненты.

Что такое 3D-фрезерный станок с ЧПУ?

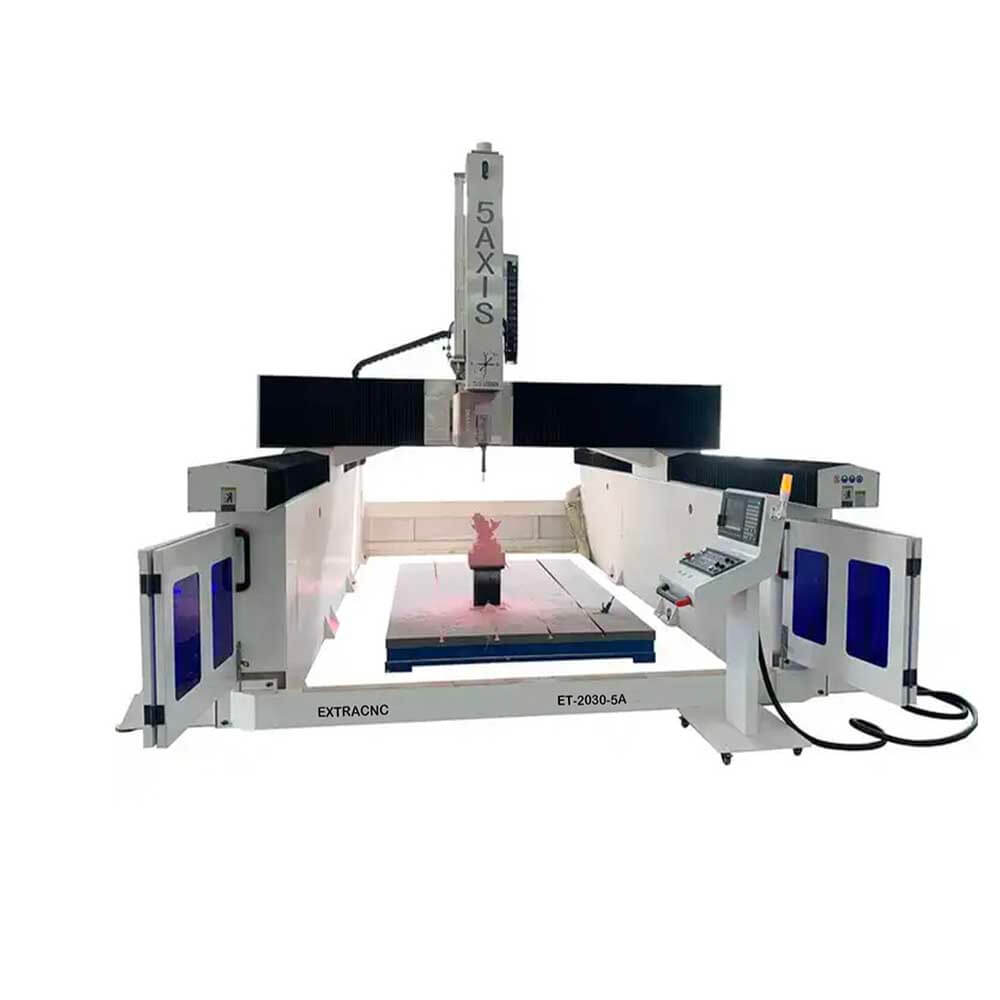

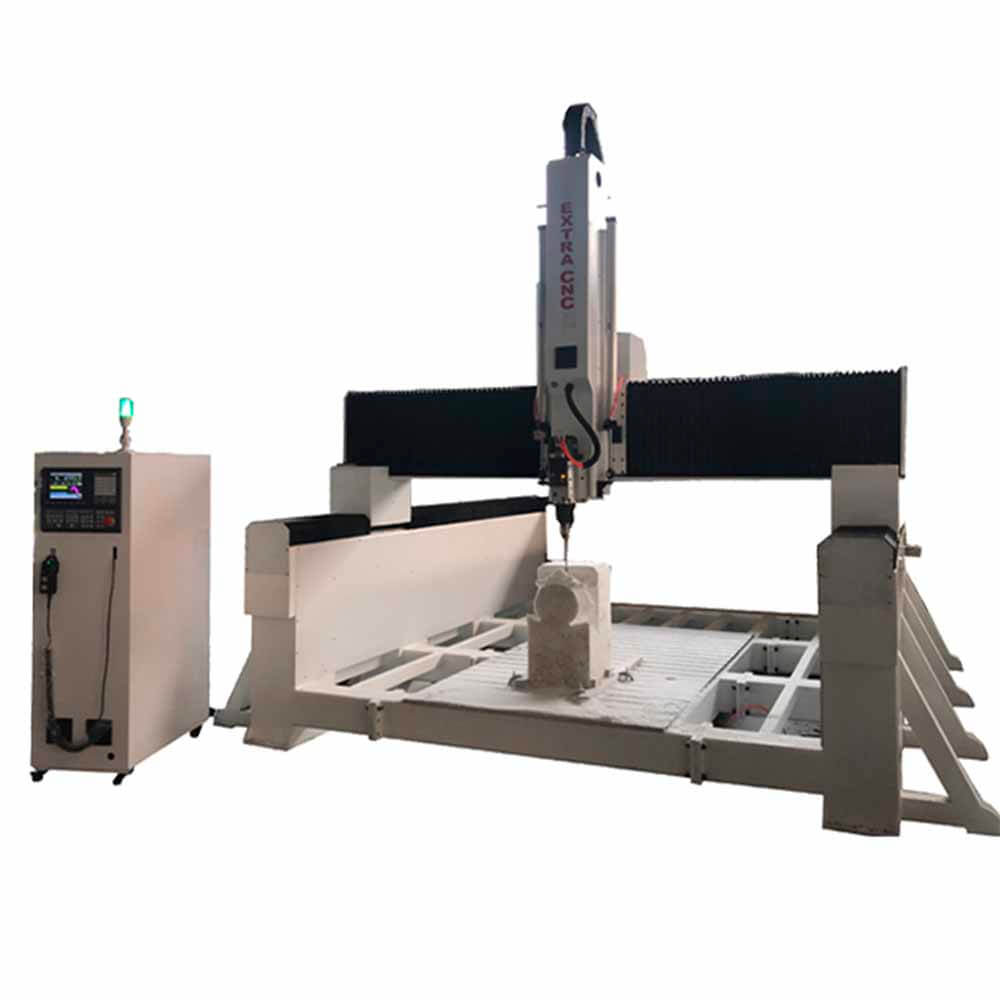

А 3D фрезерный станок с ЧПУ это тип станок с числовым программным управлением (ЧПУ) Разработан для резки, резьбы и формовки различных материалов — включая дерево, пластик, пену, цветные металлы и композиты — в сложные трехмерные формы. Оснащенный многоосевой системой, мощными шпиндельными двигателями и передовой совместимостью с программным обеспечением CAD/CAM, этот станок обеспечивает исключительную детализацию и качество поверхности как для художественных, так и для промышленных применений.

Где используется 3D-фрезерный станок с ЧПУ?

3D фрезерные станки с ЧПУ применяются в различных секторах, в том числе:

Столярные мастерские для современной резьбы по дереву и производства декоративных панелей.

Изготовление мебели на заказ для изготовления изогнутых и сложных элементов мебели.

Архитектурно-дизайнерские студии для изготовления масштабных моделей и декоративных элементов.

Рекламный и вывесочный бизнес для создания 3D-логотипов, скульптур и инсталляций.

Отрасли производства форм для прототипирования и создания точных производственных форм.

Когда 3D-фрезерные станки с ЧПУ стали незаменимыми?

Поскольку спрос на точность, индивидуализация и эффективность вырос в производственных и творческих отраслях, 3D фрезерный станок с ЧПУ появился как незаменимый инструмент в конце 20 века. Его способность автоматизировать производство подробных и сложных конструкций произвела революцию в рабочих процессах для отраслей, стремящихся к масштабируемому производству без ущерба для мастерства или точности.

Почему важен 3D-фрезерный станок с ЧПУ?

А 3D фрезерный станок с ЧПУ имеет решающее значение, поскольку оно:

Обеспечивает точную и повторяемую 3D-резьбу, фрезеровку и гравировку как для художественных, так и для промышленных изделий.

Сокращение ручного труда и человеческих ошибок, экономя время и повышая производительность.

Поддерживает универсальность использования различных материалов, позволяющий обрабатывать дерево, пенопласт, пластик, МДФ и металлы.

Увеличивает творческую свободу, что позволяет легко воплощать в жизнь сложные конструкции, скульптуры и функциональные детали.

Как работает 3D-фрезерный станок с ЧПУ?

А 3D фрезерный станок с ЧПУ работает, считывая цифровые чертежи из программного обеспечения CAD и преобразуя их в машиночитаемые траектории инструмента с помощью программного обеспечения CAM. Шпиндель маршрутизатора, управляемый многоосевой системой управления движением, перемещается по осям X, Y и Z — или даже больше в усовершенствованных 4-осевых и 5-осевых моделях — для вырезания дизайна слой за слоем. Этот точный автоматизированный процесс обеспечивает безупречную отделку поверхности, точность размеров и возможность воспроизводить сложные формы в масштабе.

Подводя итог, можно сказать, что 3D фрезерный станок с ЧПУ это оптимальное решение для любого бизнеса или дизайнера, ориентированного на резьба по дереву, изготовление форм, изготовление мебели на заказ, цифровое производство, точная гравировка и сложное прототипирование. Его способность автоматизировать производство детализированных 3D-фигур помогает компаниям повышать качество продукции, сокращать сроки выполнения заказов и расширять творческие горизонты, сохраняя при этом экономическую эффективность.