CNC EXTRA oferece um conjunto completo de soluções de fabricação avançadas e controladas por computador — apresentando roteadores CNC multieixos, máquinas de corte a plasma de alta definição, sistemas de corte a laser de fibra de precisão e máquinas de marcação de fibra duráveis — projetadas para processar madeira, metal, pedra, espuma e materiais compostos com precisão e velocidade excepcionais; confiável por fabricantes de móveis, marcenarias, fabricantes de metal, estúdios de sinalização e oficinas de fabricação de moldes, o software CAD/CAM integrado da EXTRA CNC, opções de trocador de ferramentas automatizado e recursos de encaixe otimizados maximizam a utilização do material, reduzem o desperdício e agilizam os fluxos de trabalho, fornecendo resultados consistentes e de alta qualidade e retorno rápido para protótipos personalizados e produção em larga escala.

Fornecedor profissional de fábrica de máquinas CNC EXTRA

CNC EXTRA fornece soluções de fabricação de ponta, controladas por computador — incluindo roteadores CNC, cortadores de plasma, cortadores a laser de fibra e marcadores a laser de fibra — que capacitam os fabricantes a alcançar precisão, eficiência e utilização de materiais superiores em madeira, metal, pedra, espuma e compósitos.

Quem confia nas máquinas CNC EXTRA?

Desde construtores de móveis personalizados e oficinas de marcenaria até fabricantes de automóveis, fabricantes de modelos arquitetônicos e produtores de eletrônicos, CNC's EXTRAS Nossos clientes abrangem setores que exigem precisão automatizada e repetível, além de alta produtividade. Oficinas de sinalização, especialistas em fabricação de moldes, acabamento de interiores e laboratórios de prototipagem dependem desses sistemas para transformar conceitos digitais em produtos finais impecáveis.

O que a EXTRA CNC oferece?

CNC EXTRA fornece:

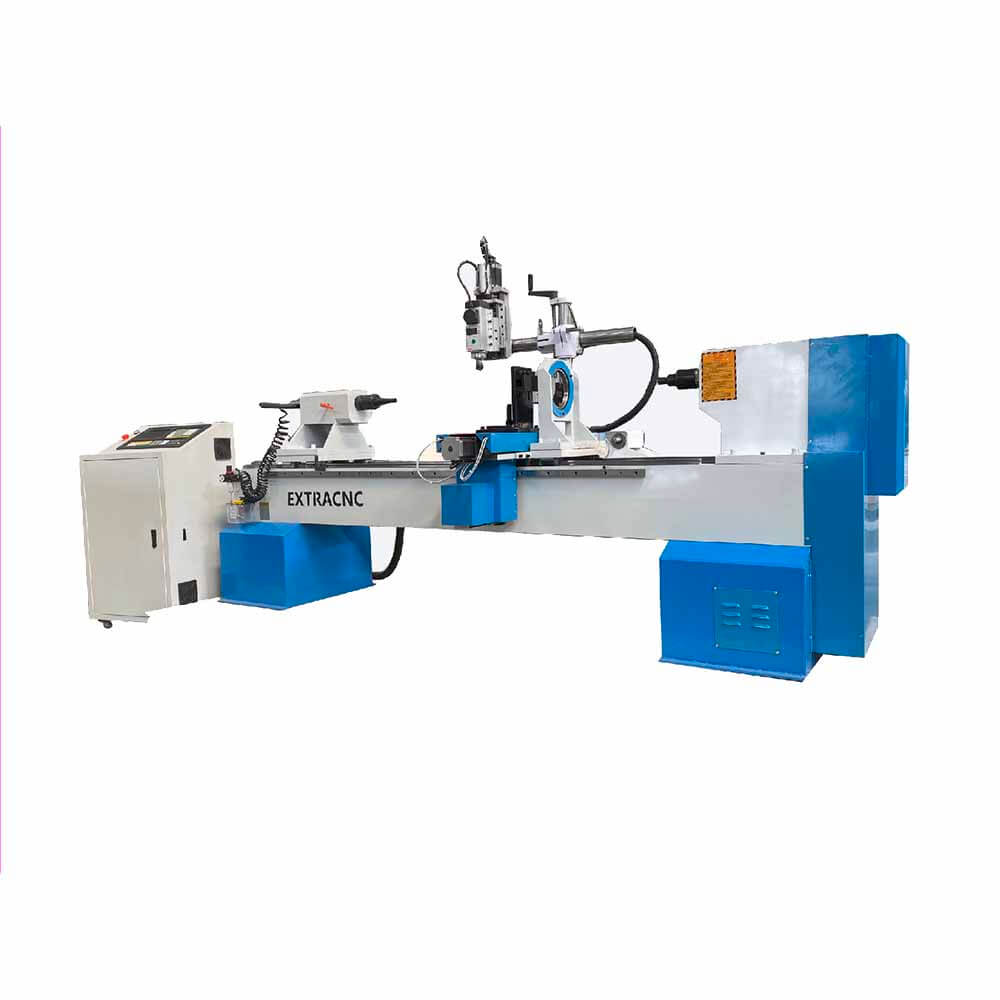

Roteadores CNC multieixos para fresamento, entalhe e perfuração complexos de madeira, plásticos e metais não ferrosos.

Cortadores de Plasma de Alta Definição que cortam aço, alumínio e ligas com corte mínimo e tempos de ciclo rápidos.

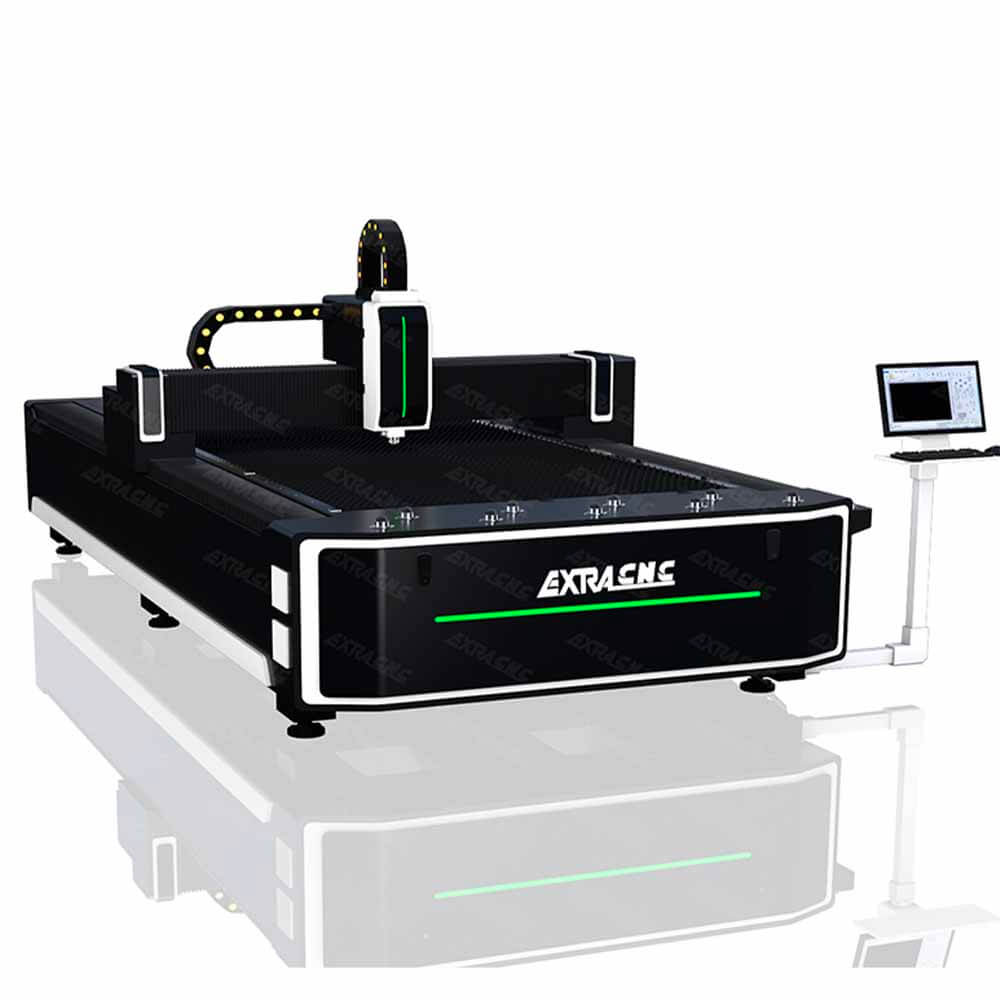

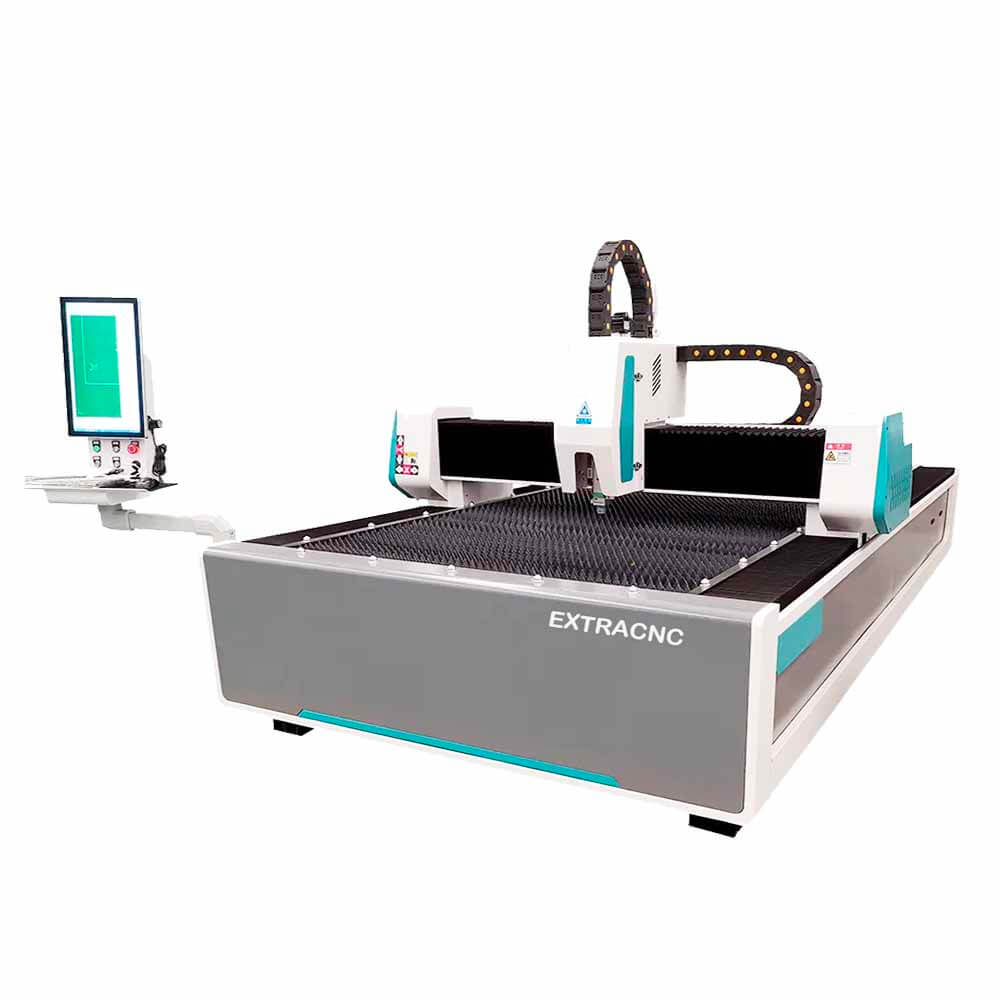

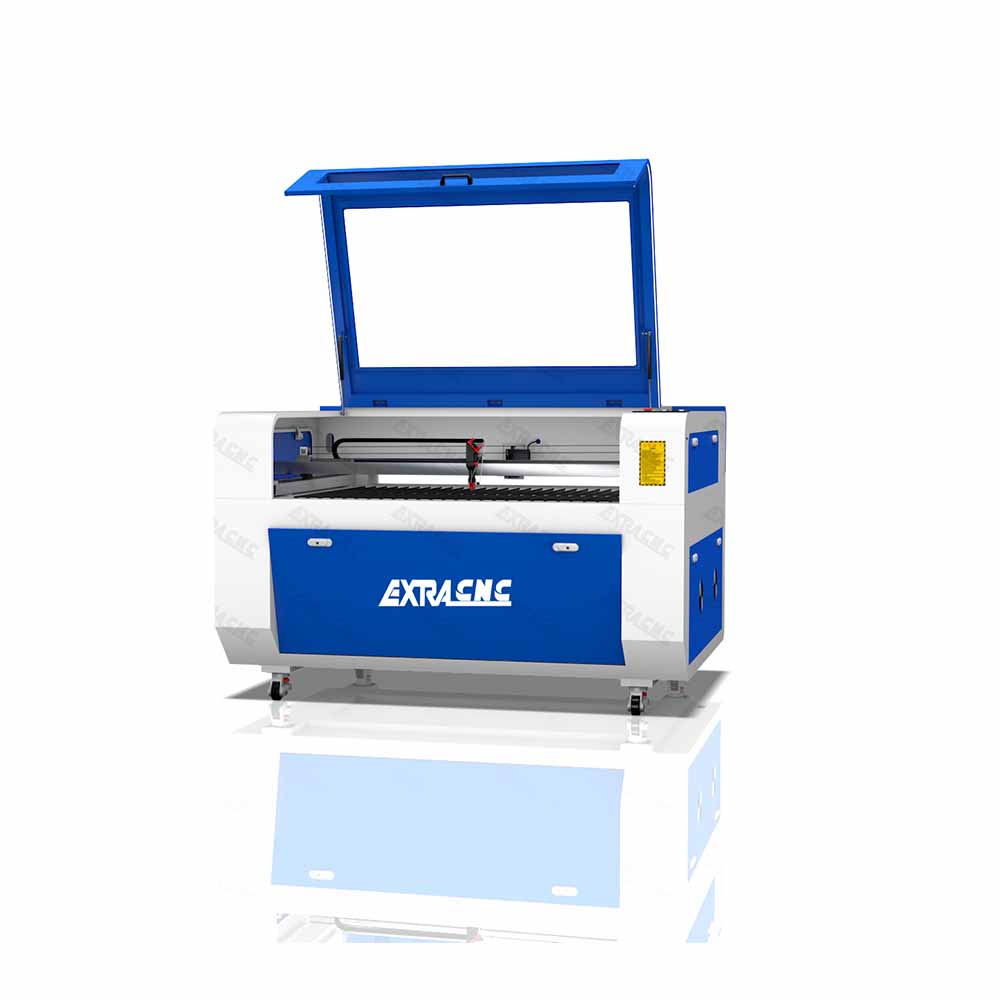

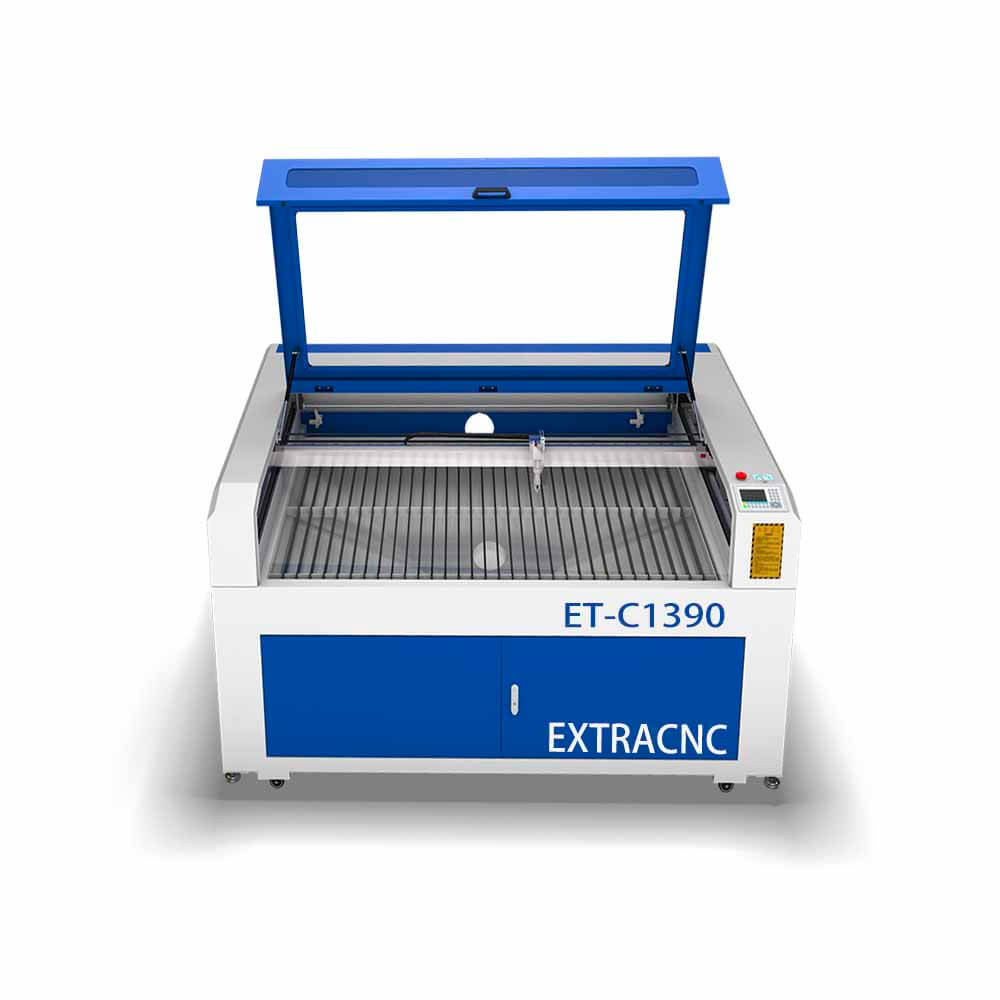

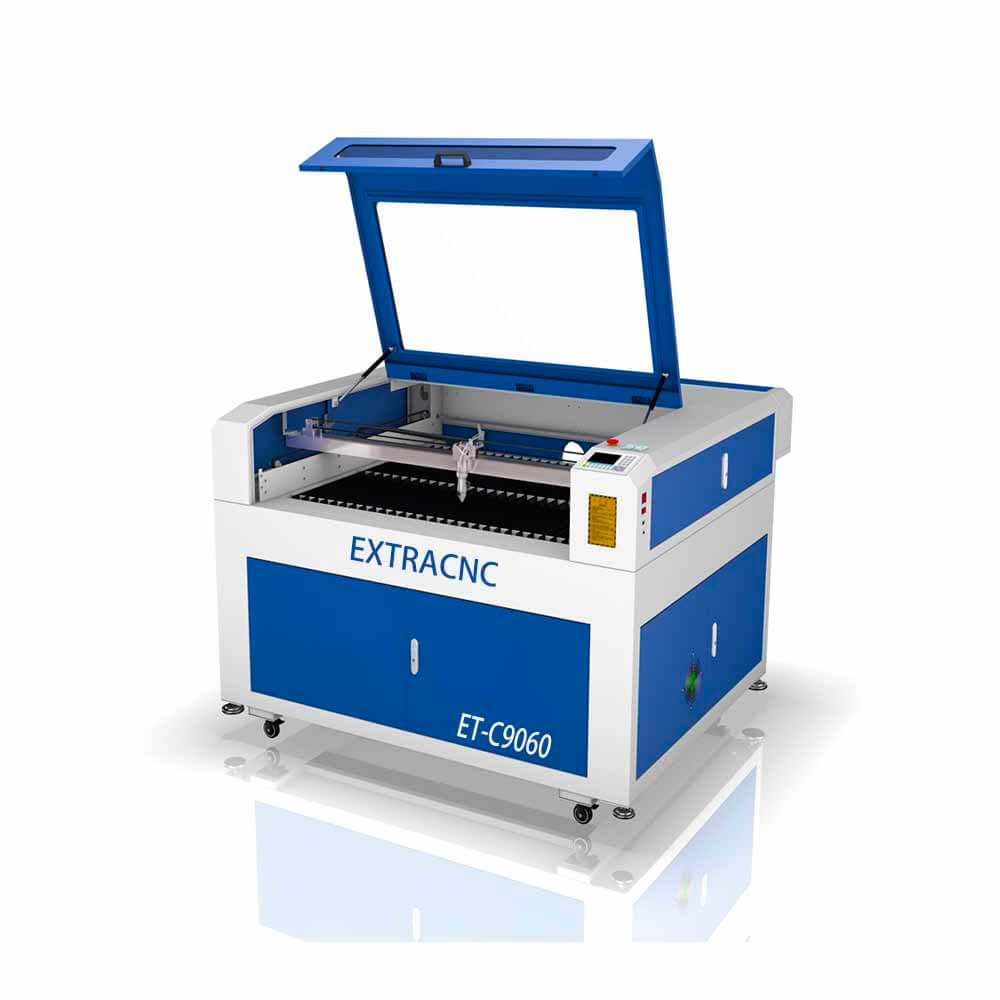

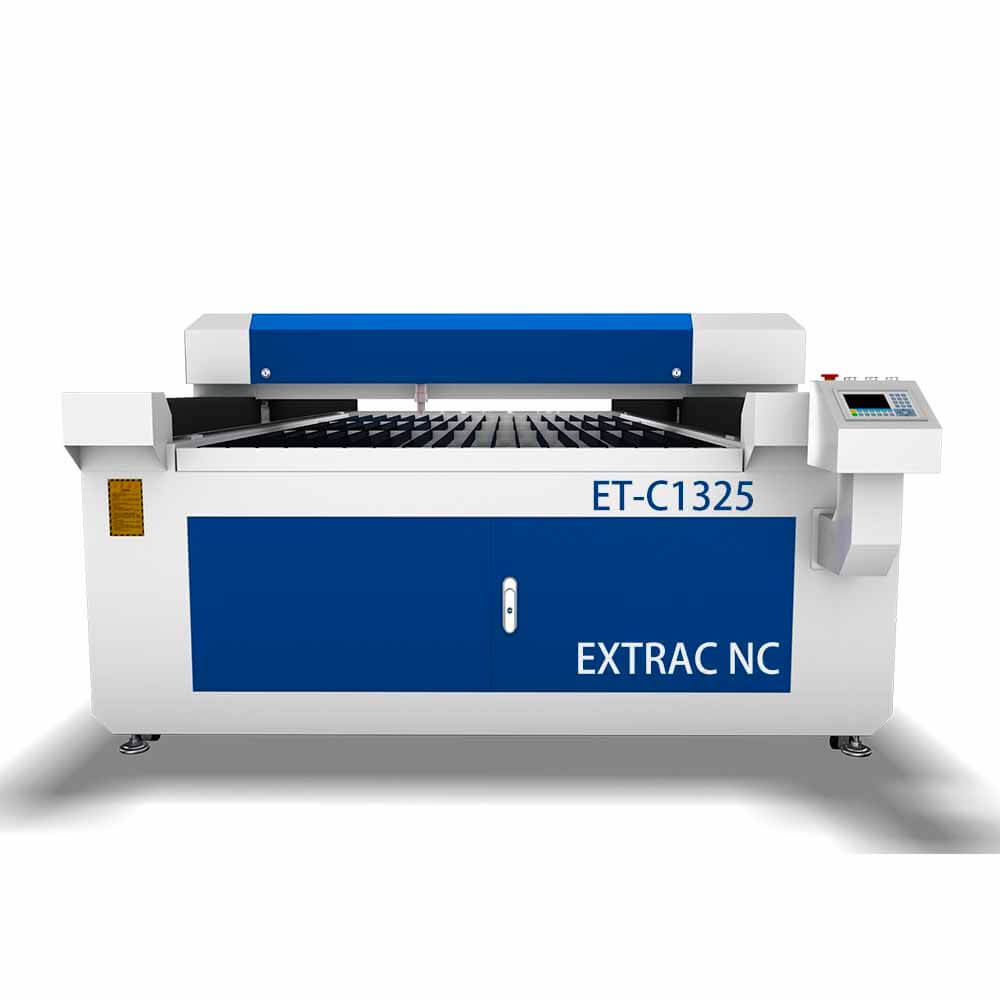

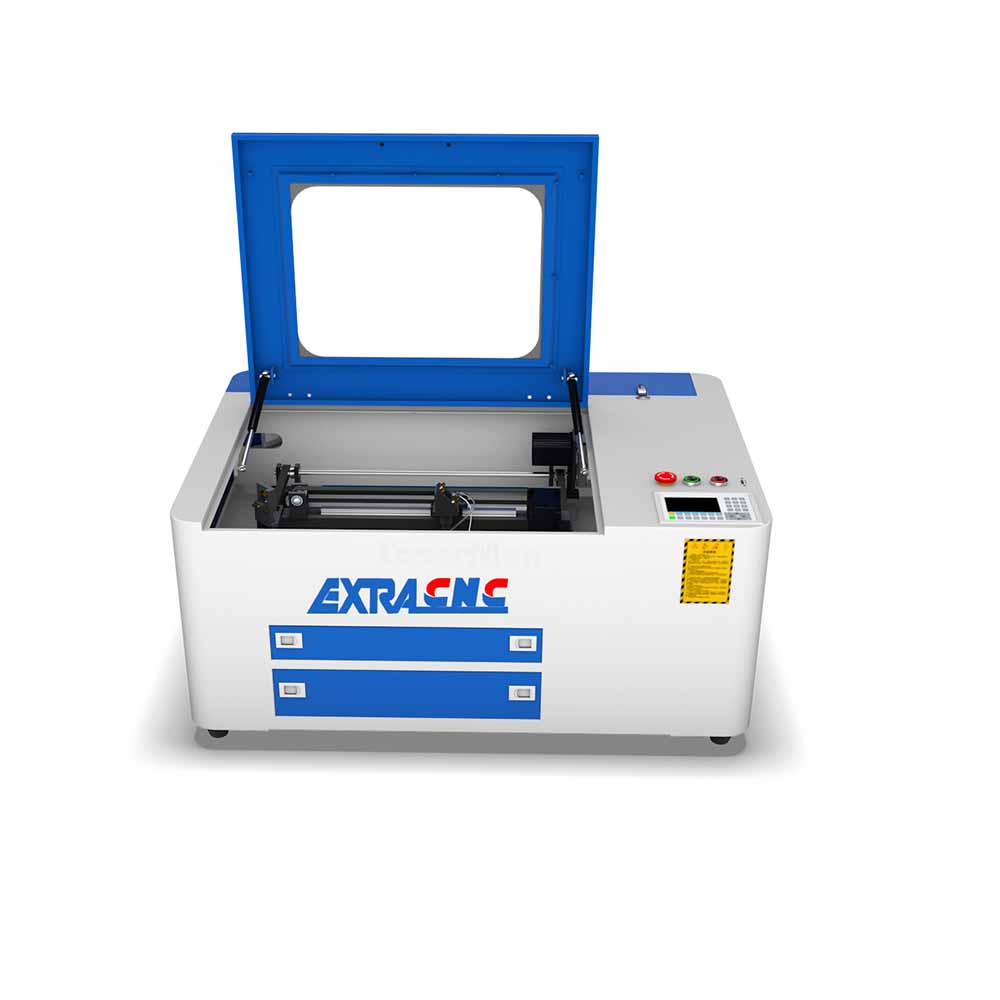

Sistemas de corte a laser de fibra aproveitando o fornecimento de feixe de alta potência para perfis de metal e corte de chapas sem rebarbas.

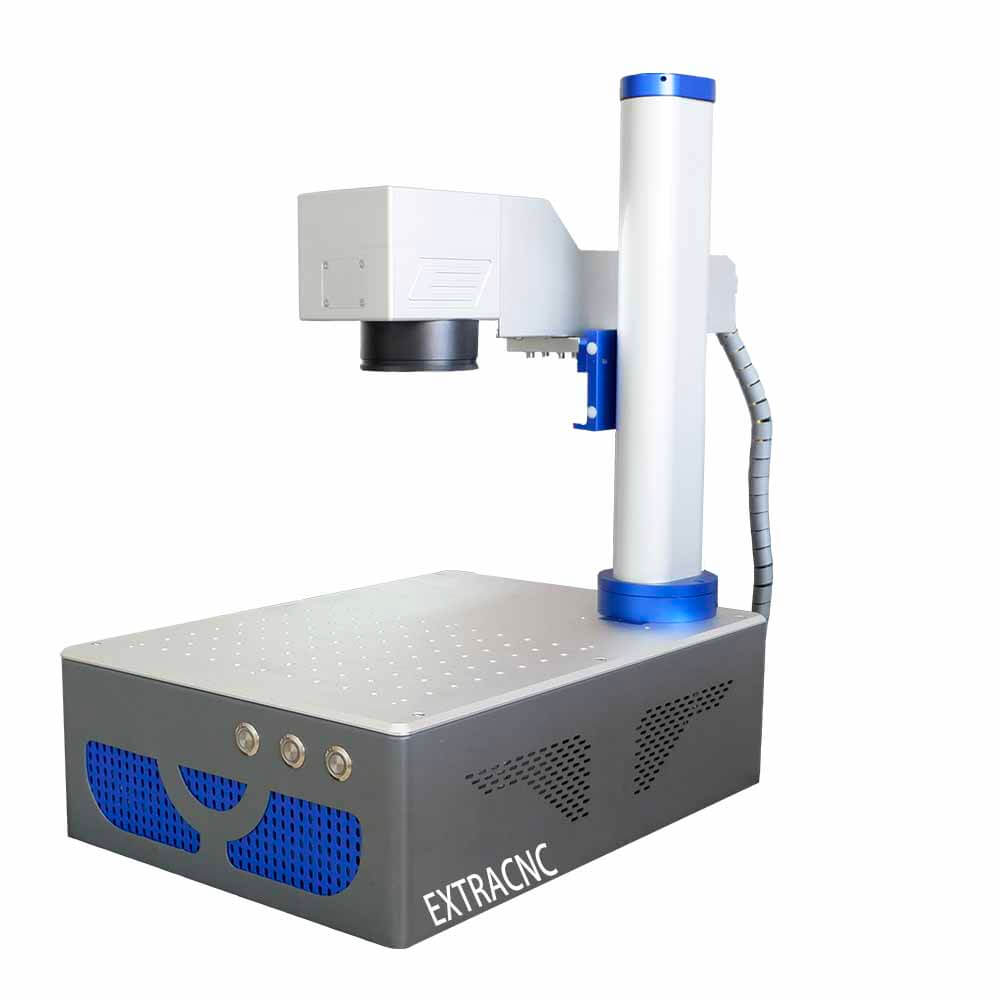

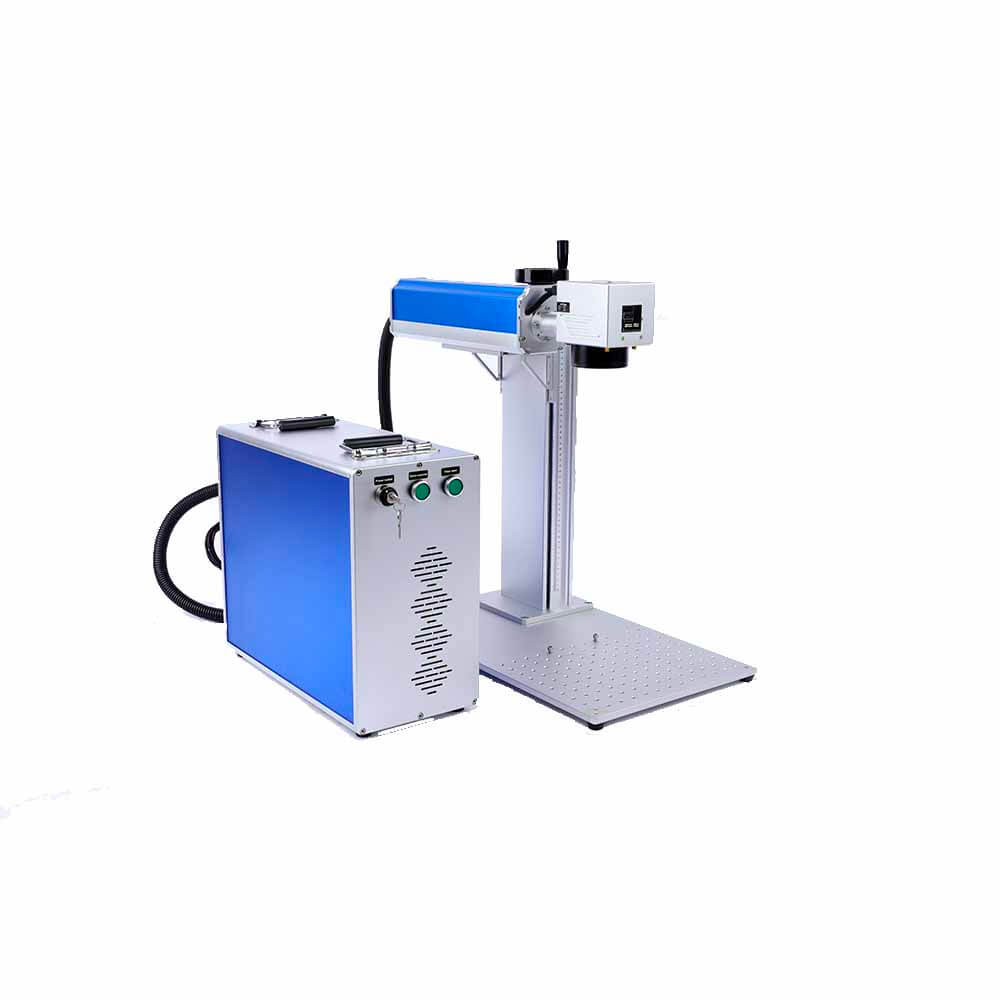

Unidades de marcação a laser de fibra que gravam, recozem ou marcam superfícies com cores para rastreabilidade e marcação.

Onde os sistemas CNC EXTRA são implantados?

Essas máquinas são parte integrante das linhas de produção em marcenarias, metalúrgicas, estúdios de escultura em pedra e oficinas de sinalização. Elas também atendem centros de pesquisa, espaços de criação e instituições educacionais onde a usinagem flexível e de alta precisão é essencial.

Quando a tecnologia EXTRA CNC se tornou indispensável?

Com base na evolução da CNC desde a década de 1970, CNC EXTRA introduziu modelos de última geração na última década — alinhando inovações de laser de fibra da década de 2000 e algoritmos de aninhamento avançados da década de 2010 — para atender à demanda atual por fabricação sob demanda e de nível personalizado.

Por que escolher a EXTRA CNC?

Produtividade aprimorada: Trocas automatizadas de ferramentas e aninhamento otimizado maximizam a produtividade e reduzem o tempo de inatividade.

Economia de custos: Corte preciso e desperdício mínimo reduzem custos de material e despesas de mão de obra.

Qualidade consistente: Tolerâncias rigorosas e fluxos de trabalho controlados por CNC garantem resultados repetíveis e de alta qualidade.

Versatilidade: Uma única plataforma lida com diversas tarefas — desde escultura 3D e corte de metal em alta velocidade até marcação e gravação finas.

Como funcionam as máquinas CNC EXTRA

Design digital e configuração CAM: Engenheiros criam modelos em software CAD e geram código G ou layouts de aninhamento otimizados.

Execução de controle CNC: O controlador integrado aciona fusos, tochas ou cabeçotes de laser ao longo de vários eixos, seguindo trajetórias de ferramentas precisas.

Gestão Avançada de Processos: Os sistemas de plasma regulam o fluxo de gás e os parâmetros do arco; os lasers de fibra modulam a potência e o foco do feixe; os roteadores ajustam as taxas de alimentação e as velocidades do eixo.

Trocas automatizadas de ferramentas e cabeçotes: Mecanismos ATC ou de troca rápida integrados simplificam as transições entre brocas, cortadores e marcadores sem intervenção manual.

Pós-processamento e inspeção de qualidade: As peças acabadas passam por operações secundárias mínimas, com sondas integradas ou sistemas de visão verificando a precisão dimensional.

Ao escolher CNC EXTRA, as empresas desbloqueiam uma plataforma de fabricação pronta para uso que simplifica os fluxos de trabalho, minimiza o desperdício e pode ser dimensionada sem esforço, desde execuções de protótipos até volumes de produção completos, impulsionando a excelência operacional no competitivo ambiente de fabricação atual.