Roteador CNC de encaixe

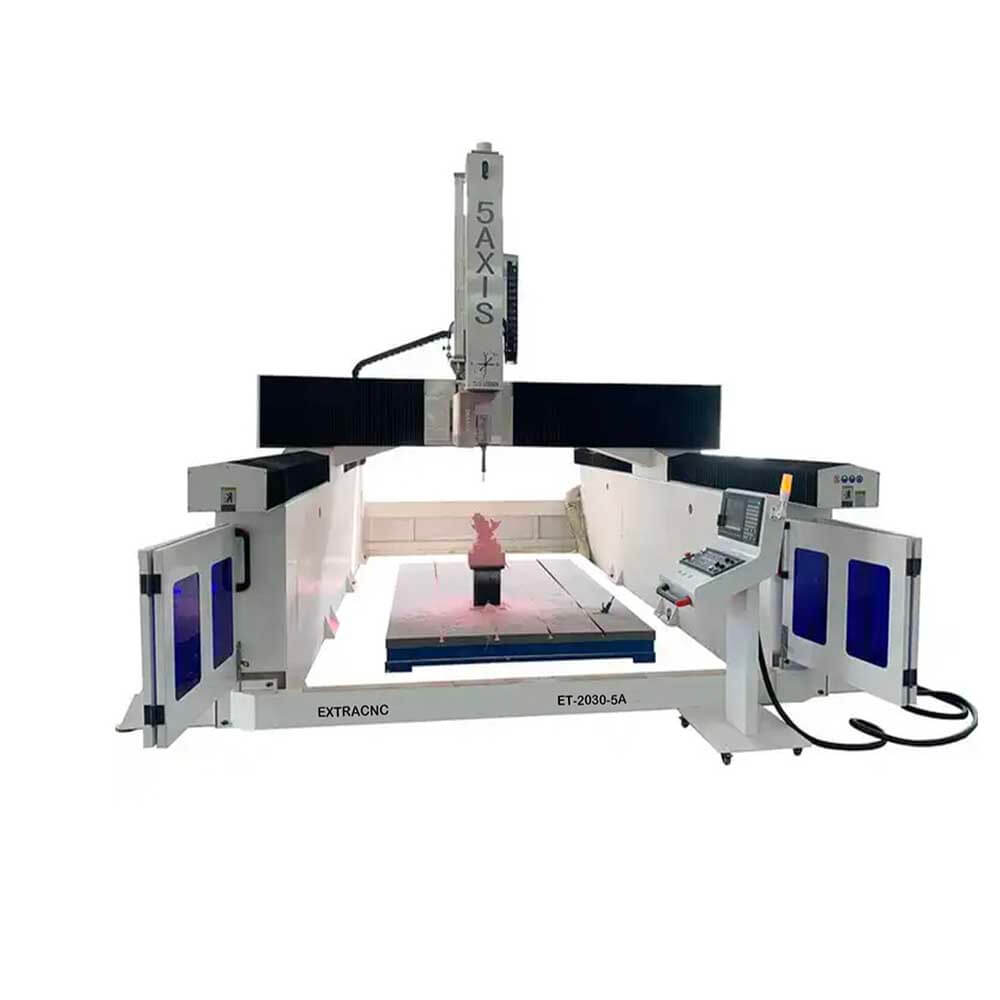

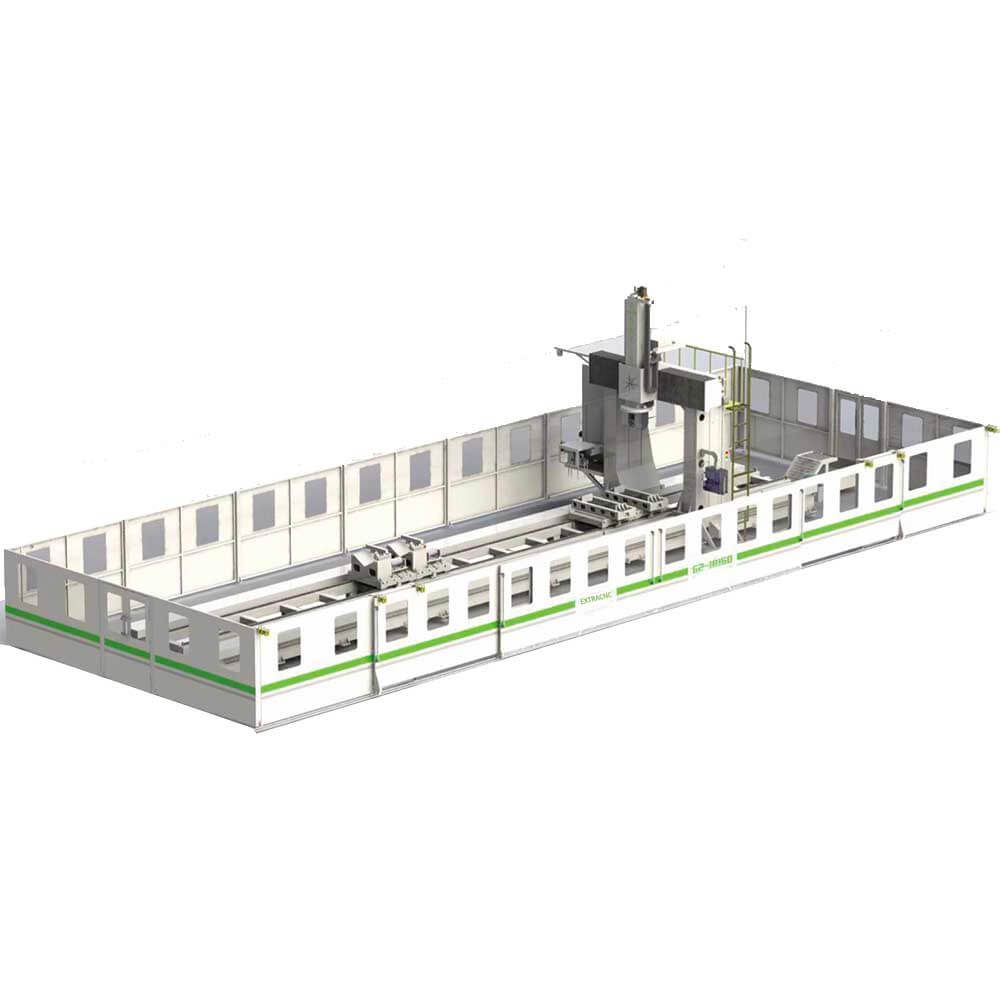

UM Roteador CNC de encaixe é uma máquina de corte avançada, controlada por computador, projetada para otimização eficiente de materiais nos setores de marcenaria, marcenaria, produção de móveis e decoração de interiores. Utilizando um software de encaixe inteligente, esta fresadora CNC organiza múltiplas peças em uma única chapa para minimizar o desperdício e maximizar a produtividade. Seja cortando MDF, compensado, aglomerado ou painéis compostos, uma fresadora CNC de encaixe garante uma produção precisa, repetível e de alta velocidade, tornando-se a solução ideal para empresas que buscam reduzir custos, melhorar a precisão do corte e otimizar o fluxo de trabalho em ambientes de produção personalizada e em massa.

UM Roteador CNC de encaixe é uma máquina de corte de alta precisão controlada por computador, projetada especificamente para otimizar o uso de materiais e agilizar processos de produção em setores como fabricação de móveis, marcenaria, marcenaria e decoração de interiores. Conhecida por sua eficiência excepcional no corte e encaixe de múltiplas peças a partir de uma única chapa, esta solução CNC avançada ajuda as empresas a minimizar o desperdício e, ao mesmo tempo, maximizar a produtividade.

Quem usa uma fresadora CNC aninhada?

Roteadores CNC aninhados são amplamente utilizados por fabricantes de móveis, marcenarias personalizadas, profissionais de marcenaria, designers de interiores e empresas de sinalização. Esses usuários dependem da tecnologia de encaixe para automatizar o corte de formas complexas de grandes materiais em folha, como MDF, compensado, aglomerado, acrílico e painéis compostos, com precisão e desperdício mínimo.

O que é um roteador CNC aninhado?

UM Roteador CNC de encaixe é uma máquina de corte CNC especializada, equipada com software avançado e sistemas de otimização de trajetória de ferramentas que permitem aos usuários "aninhar" ou organizar múltiplas peças em uma única folha de material para máxima eficiência de espaço. Ela não apenas realiza cortes precisos, como também realiza furação, ranhura, gravação e abertura de cavidades, tornando-se um recurso versátil tanto para produção em massa quanto para fluxos de trabalho de projetos personalizados.

Onde um roteador CNC de encaixe é utilizado?

Essas máquinas são utilizadas principalmente em:

Oficinas de fabricação de armários para cortar painéis e componentes.

Fábricas de móveis para produção de peças de móveis embaladas em embalagens planas.

Negócios de decoração de interiores para painéis personalizados, portas e elementos decorativos de parede.

Indústrias de marcenaria e sinalização para criar componentes funcionais e estéticos.

Quando os roteadores CNC aninhados se tornaram essenciais?

Roteadores CNC aninhados tornou-se essencial à medida que a demanda por móveis personalizados, soluções de embalagem plana e produção eficiente de marcenaria cresceu no final da década de 1990 e início dos anos 2000. À medida que a fabricação digital e a otimização automatizada de materiais evoluíram, essas máquinas ofereceram uma solução para reduzir custos de produção, desperdício de material e tempo de mão de obra, tornando-as indispensáveis para empresas que buscam alta eficiência e precisão.

Por que uma fresadora CNC aninhada é importante?

UM Roteador CNC de encaixe é vital porque ajuda as empresas a:

Maximizar a utilização do material organizando as peças com precisão para reduzir sobras e desperdícios.

Melhore a eficiência da produção por meio de fluxos de trabalho de corte, perfuração e gravação totalmente automatizados.

Aumente a precisão e a qualidade minimizando erros humanos e garantindo precisão repetível em grandes lotes de produção.

Menores custos de mão de obra e materiais simplificando as operações e otimizando cada folha utilizada no processo de corte.

Como funciona uma fresadora CNC aninhada?

A operação de um Roteador CNC de encaixe começa com a criação de um layout digital em um software especializado em nesting. O software organiza automaticamente as formas ou peças desejadas na chapa de matéria-prima para maximizar a eficiência do corte. Uma vez otimizado o projeto, a máquina CNC segue o caminho da ferramenta programado, utilizando seu fuso de alta velocidade e sistema de controle de precisão para cortar, fresar, furar e gravar cada peça diretamente da chapa. Esse processo contínuo reduz significativamente o tempo de preparação e o desperdício, oferecendo velocidade e precisão superiores.

Em resumo, um Roteador CNC de encaixe é a solução perfeita para qualquer empresa que pretenda melhorar produtividade, precisão e eficiência de materiais nos campos de marcenaria, marcenaria, produção de móveis personalizados e fabricação digital. Não importa se você fabrica móveis desmontáveis ou componentes internos personalizados, esta máquina potencializará seu fluxo de trabalho com uso otimizado de folhas, tempos de resposta rápidos e precisão de nível profissional.