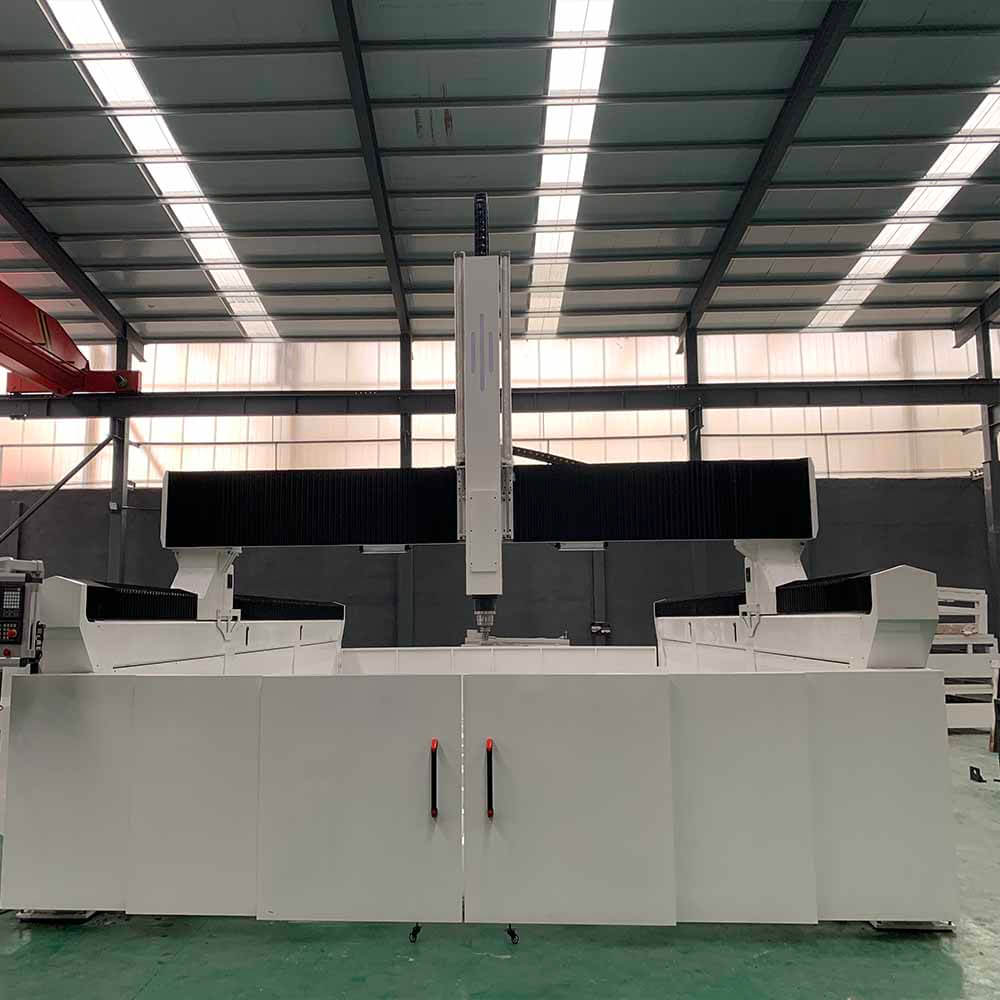

Roteador CNC ATC

Um Roteador CNC ATC é uma máquina automatizada de alta precisão projetada para usinagem eficiente e versátil de madeira e materiais compósitos. Ao integrar a avançada tecnologia de Trocador Automático de Ferramentas (ATC), este sistema de ponta elimina as trocas manuais de ferramentas, permitindo processos contínuos e multioperacionais, como fresamento, gravação, entalhe e furação em indústrias como marcenaria, fabricação de móveis personalizados, marcenaria e fabricação digital. A Fresadora CNC ATC aumenta a produtividade e a precisão ao alternar rapidamente entre diferentes ferramentas, reduzindo o tempo de inatividade e minimizando o erro humano. Amplamente utilizada em ambientes de produção em larga escala, ela garante resultados de alta qualidade, tolerâncias rigorosas e tempos de resposta mais rápidos, tornando-se um recurso essencial para fabricantes profissionais que buscam otimizar suas operações. Como resultado, essa tecnologia proporciona um retorno significativo sobre o investimento, otimizando a eficiência, melhorando o acabamento da superfície e aprimorando a precisão geral da fabricação, tornando-a indispensável em aplicações modernas de roteamento CNC.

Um Roteador CNC ATC é uma máquina de controle numérico computadorizado de última geração com Trocador Automático de Ferramentas (ATC), projetada especificamente para otimizar a usinagem de madeira e materiais compósitos de alto volume e precisão. Ao integrar a tecnologia ATC avançada com recursos robustos de roteamento, esta máquina é um recurso essencial em ambientes de manufatura modernos, desde marcenaria industrial e marcenaria até fabricação de móveis personalizados e projetos complexos de fabricação digital.

Quem usa uma fresadora CNC ATC?

Marceneiros profissionais, fabricantes de móveis e fabricantes industriais confiam na fresadora CNC ATC para aumentar a produtividade e manter resultados consistentes e de alta qualidade. Seu recurso de troca automatizada de ferramentas é particularmente benéfico para indústrias que exigem tempos de resposta rápidos com intervenção manual mínima, como a produção em massa na marcenaria e a usinagem multi-operação complexa na fabricação de móveis personalizados.

O que é um roteador CNC ATC?

Uma fresadora CNC ATC é um sistema de usinagem sofisticado, controlado por computador, que conta com um trocador automático de ferramentas. Este sistema permite que a fresadora alterne rapidamente entre diferentes ferramentas de corte durante um único ciclo de usinagem, melhorando assim a eficiência e a precisão. Ela é projetada para tarefas como fresamento, gravação, entalhe e furação, essenciais para operações de fabricação digital e marcenaria de ponta.

Onde é utilizado?

As fresadoras CNC ATC são amplamente utilizadas em instalações de produção, oficinas mecânicas profissionais e unidades de fabricação em larga escala. São ideais para ambientes onde tarefas complexas de usinagem são comuns — por exemplo, na produção de armários personalizados, painéis decorativos de madeira e componentes cortados com precisão para móveis e projetos arquitetônicos.

Quando se tornou essencial?

A integração da tecnologia ATC em sistemas de roteamento CNC evoluiu nas últimas décadas, à medida que as empresas buscam cada vez mais reduzir o tempo de inatividade da produção e aprimorar a precisão da fabricação. Com o rápido avanço dos softwares CAD/CAM e a crescente demanda por projetos complexos de madeira, a fresadora CNC ATC emergiu como uma ferramenta indispensável tanto na fabricação comercial de alto volume quanto em ambientes avançados de prototipagem.

Por que um roteador CNC ATC é importante?

A fresadora CNC ATC aumenta significativamente a produtividade, eliminando as frequentes trocas manuais de ferramentas, que tradicionalmente desaceleram os ciclos de produção e introduzem a possibilidade de erro humano. Sua capacidade de alternar rapidamente entre múltiplas ferramentas de corte permite transições mais suaves entre as operações de usinagem, resultando em melhor acabamento superficial, tolerâncias mais rigorosas e redução do tempo total de usinagem. Isso resulta em maior produtividade e um retorno superior sobre o investimento para empresas focadas em fabricação digital e marcenaria automatizada.

Como funciona um roteador CNC ATC?

A operação de uma fresadora CNC ATC começa com projetos detalhados criados em software CAD, que são então convertidos em trajetórias de ferramentas precisas por meio de software CAM. O controlador CNC da máquina segue essas instruções para mover seu fuso ao longo dos eixos X, Y e Z, enquanto um trocador de ferramentas automatizado — integrado ao sistema — troca as ferramentas de corte conforme necessário. Essa automação permite que processos de usinagem em várias etapas, como furação, fresamento e gravação, ocorram consecutivamente sem intervenção manual, garantindo alta precisão e consistência em todo o processo de produção.

Em resumo, a fresadora CNC ATC representa um avanço significativo na tecnologia de usinagem automatizada. Ao combinar os benefícios de um trocador automático de ferramentas com a precisão e a eficiência da fresagem CNC, ela oferece uma solução poderosa, sob medida para atender às rigorosas demandas dos setores modernos de marcenaria, marcenaria CNC e fabricação digital. Sua capacidade de gerenciar tarefas complexas em uma única configuração não só economiza tempo, como também proporciona consistência e qualidade incomparáveis, tornando-a um investimento essencial para fabricantes com visão de futuro.