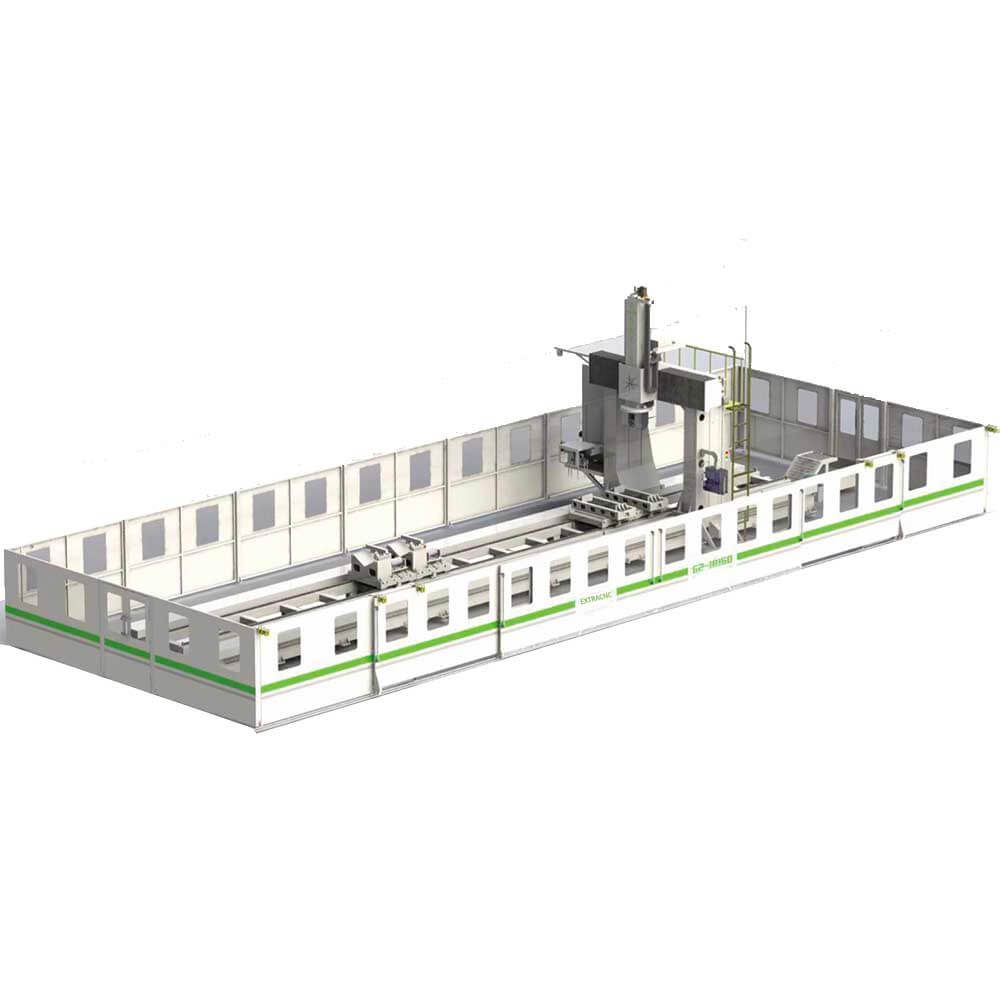

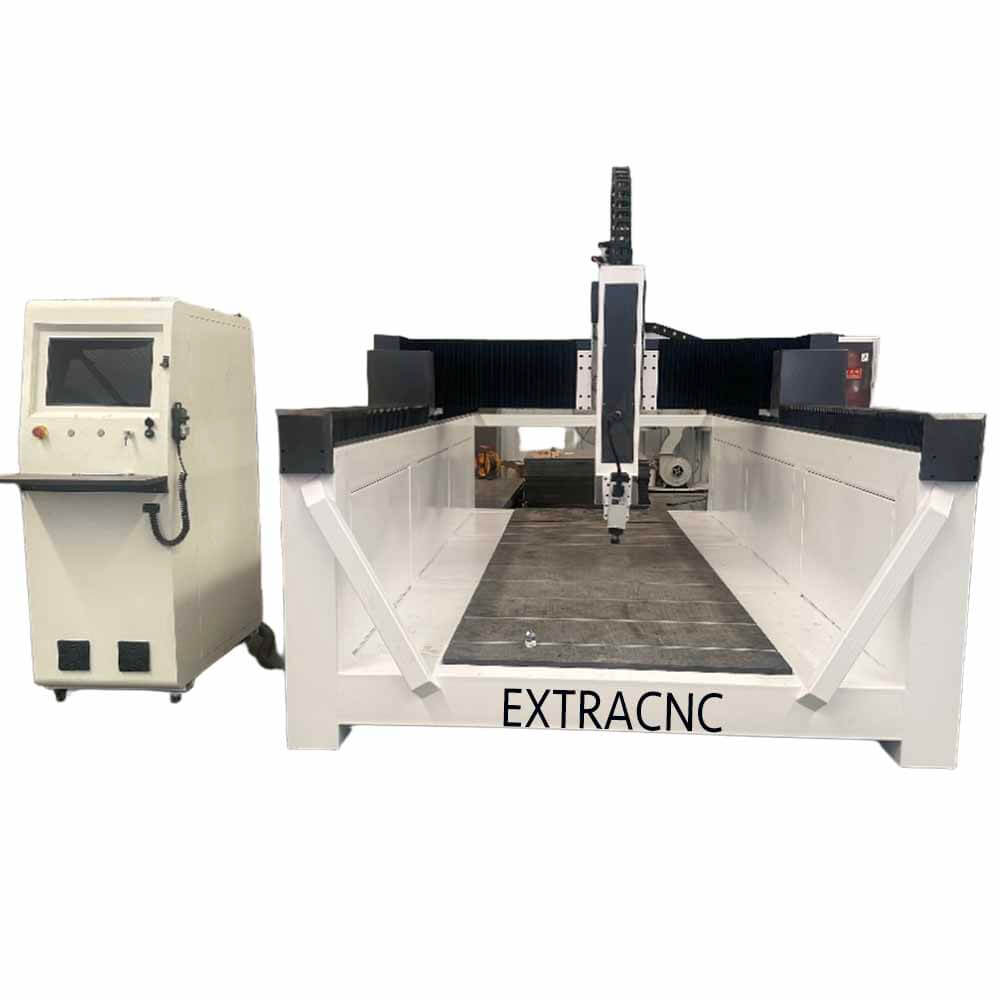

Roteador CNC de 4 eixos

Uma fresadora CNC de 4 eixos é um sistema de corte de alta precisão controlado por computador que integra um quarto eixo rotacional (comumente denominado eixo A) com os movimentos padrão X, Y e Z, permitindo que fabricantes — desde marcenaria e fabricação de moldes até publicidade e produção de móveis — produzam com eficiência designs complexos e multidimensionais em uma única configuração; essa tecnologia, que surgiu junto com os avanços nos sistemas de controle CAD/CAM e CNC, permite usinagem simultânea de vários lados que reduz o reposicionamento manual, minimiza erros e melhora a produtividade geral, tornando-se uma ferramenta essencial para indústrias modernas que buscam obter geometrias complexas, acabamentos de superfície superiores e tolerâncias rigorosas em um processo ininterrupto.

Uma fresadora CNC de 4 eixos é um sistema de corte automatizado de última geração que amplia a capacidade tradicional de usinagem de três eixos (X, Y, Z) com um eixo rotacional adicional, comumente denominado eixo A. Esse grau extra de liberdade permite a usinagem simultânea de vários lados, possibilitando a produção de superfícies curvas complexas, componentes cilíndricos e geometrias complexas com precisão e eficiência notáveis.

Quem usa?

Indústrias como marcenaria, publicidade, fabricação de moldes, fabricação de móveis e até mesmo engenharia de protótipos contam com roteadores CNC de 4 eixos. Elas são ideais para empresas e profissionais que exigem alta precisão e a capacidade de concluir projetos multifacetados em uma única configuração.

O que é?

Em sua essência, a fresadora CNC de 4 eixos integra um componente rotacional extra ao processo padrão de usinagem de três eixos. Este quarto eixo adicional permite que a peça gire, possibilitando a usinagem de múltiplas faces sem a necessidade de refixação manual. O resultado é a redução do tempo de produção, menos erros e a capacidade de obter designs 3D complexos que seriam difíceis ou impossíveis usando apenas movimentos lineares.

Onde é usado?

De pisos de produção industriais de ponta e oficinas profissionais à fabricação em pequena escala e instalações avançadas para amadores, essas máquinas são versáteis o suficiente para operar em diversos ambientes. São particularmente valorizadas em regiões com indústrias de manufatura em evolução e em instalações onde precisão e repetibilidade são essenciais.

Quando se tornou essencial?

A evolução de máquinas convencionais de 3 eixos para sistemas multieixos, como fresadoras CNC de 4 eixos, representa um marco significativo na manufatura moderna. À medida que as tecnologias CAD/CAM e os sistemas de controle numérico avançavam, a demanda por máquinas capazes de processar geometrias complexas em uma única operação ininterrupta cresceu, posicionando a fresadora de 4 eixos como uma ferramenta essencial para uma fabricação eficiente e inovadora.

Por que isso é importante?

Um dos principais benefícios da fresadora CNC de 4 eixos é a capacidade de usinar peças em vários lados com uma única instalação. Isso não só aumenta a produtividade, eliminando a necessidade de refixação e realinhamento repetidos, como também melhora a precisão das peças e o acabamento superficial. Além disso, seus recursos aprimorados abrem caminho para a flexibilidade de design, permitindo que os fabricantes executem projetos complexos — como entalhes em arco para portas, pernas de móveis personalizadas e sinalização detalhada — com facilidade.

Como funciona?

A máquina opera coordenando movimentos ao longo de três eixos lineares, combinados com o movimento rotacional proporcionado pelo eixo A. O controlador integrado processa trajetórias de ferramentas complexas geradas por CAM, que direcionam o fuso para executar operações multieixo simultâneas. Esse movimento sincronizado permite que a fresadora faça a transição perfeita de um lado da peça para o outro, alcançando uma usinagem verdadeiramente 3D sem comprometer a velocidade ou a precisão.

Em resumo, a fresadora CNC de 4 eixos representa um avanço significativo na usinagem automatizada, oferecendo flexibilidade, eficiência e precisão incomparáveis. Seu design e recursos não apenas otimizam os fluxos de trabalho de produção, mas também capacitam os fabricantes a explorar novas possibilidades criativas em design e fabricação, tornando-a um recurso valioso no competitivo mercado atual.