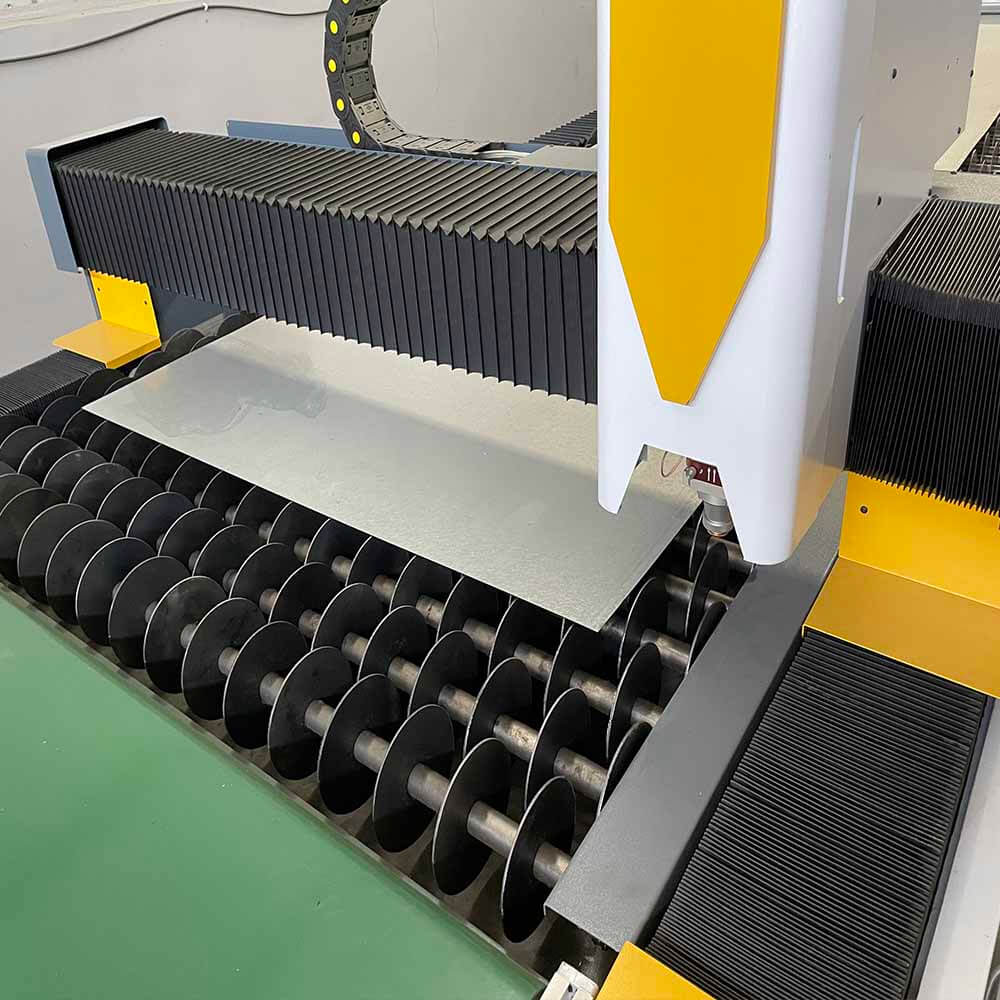

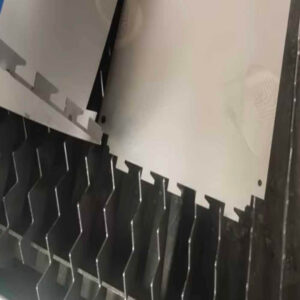

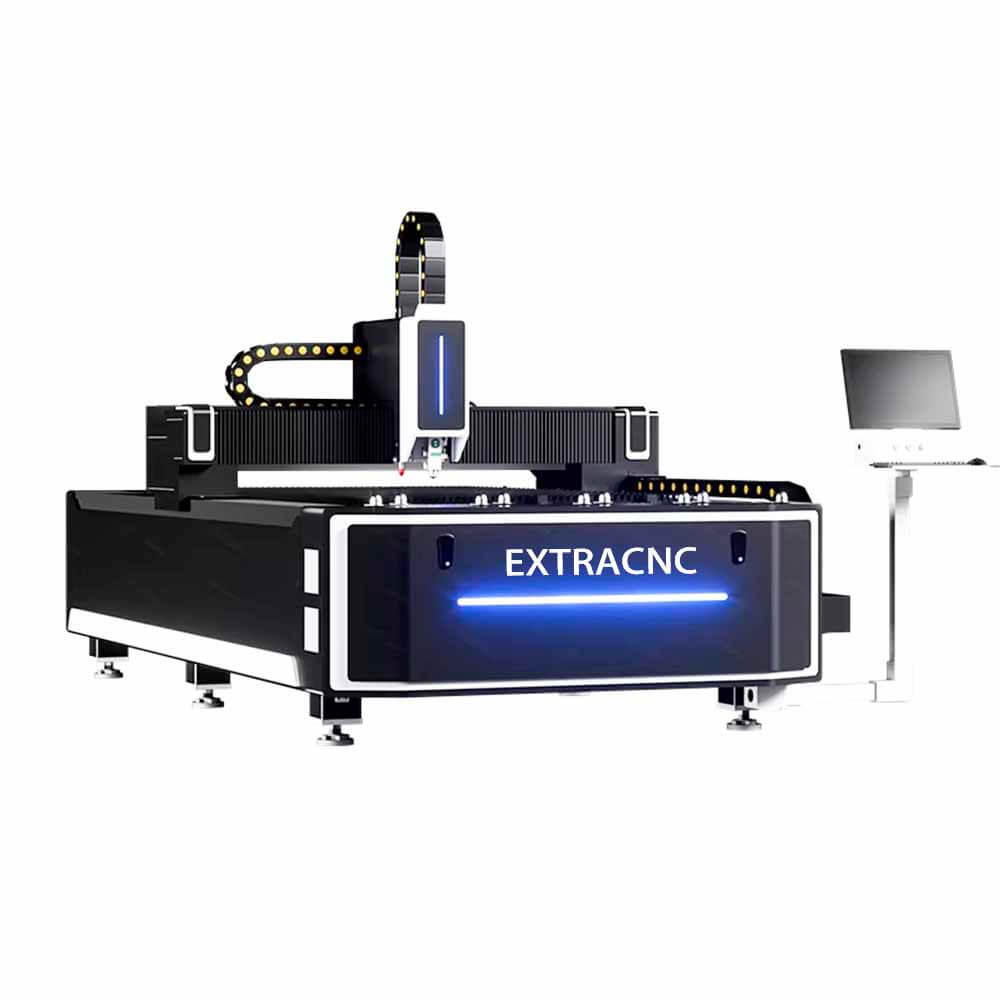

O Corte automático a laser de fibra alimentado por bobina Sistema É ideal para cortar bobinas metálicas como aço inoxidável, alumínio e aço carbono. É amplamente utilizado em indústrias como HVAC, automotivo, agricultura, equipamento médico, construção, e fabricação de metais, oferecendo corte eficiente e de alta qualidade para uma variedade de aplicações.