Schuim/EPS CNC-freesmachine

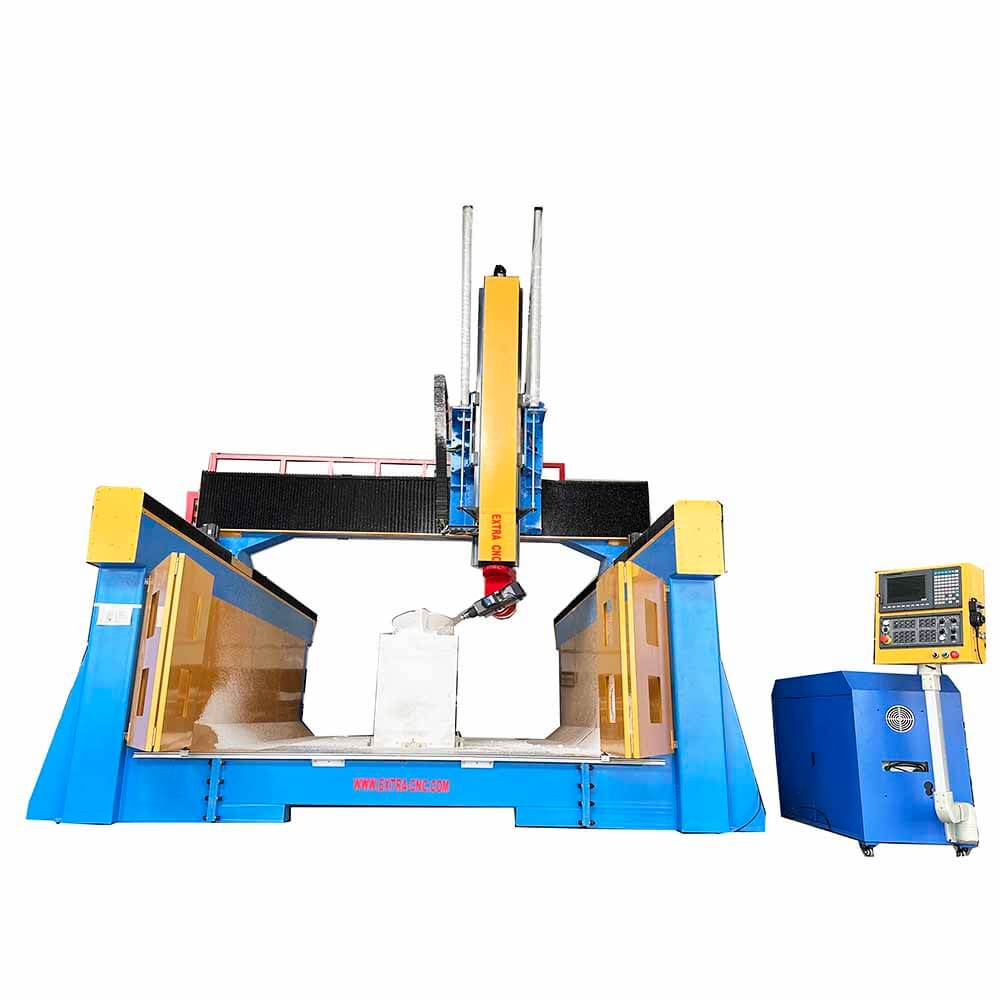

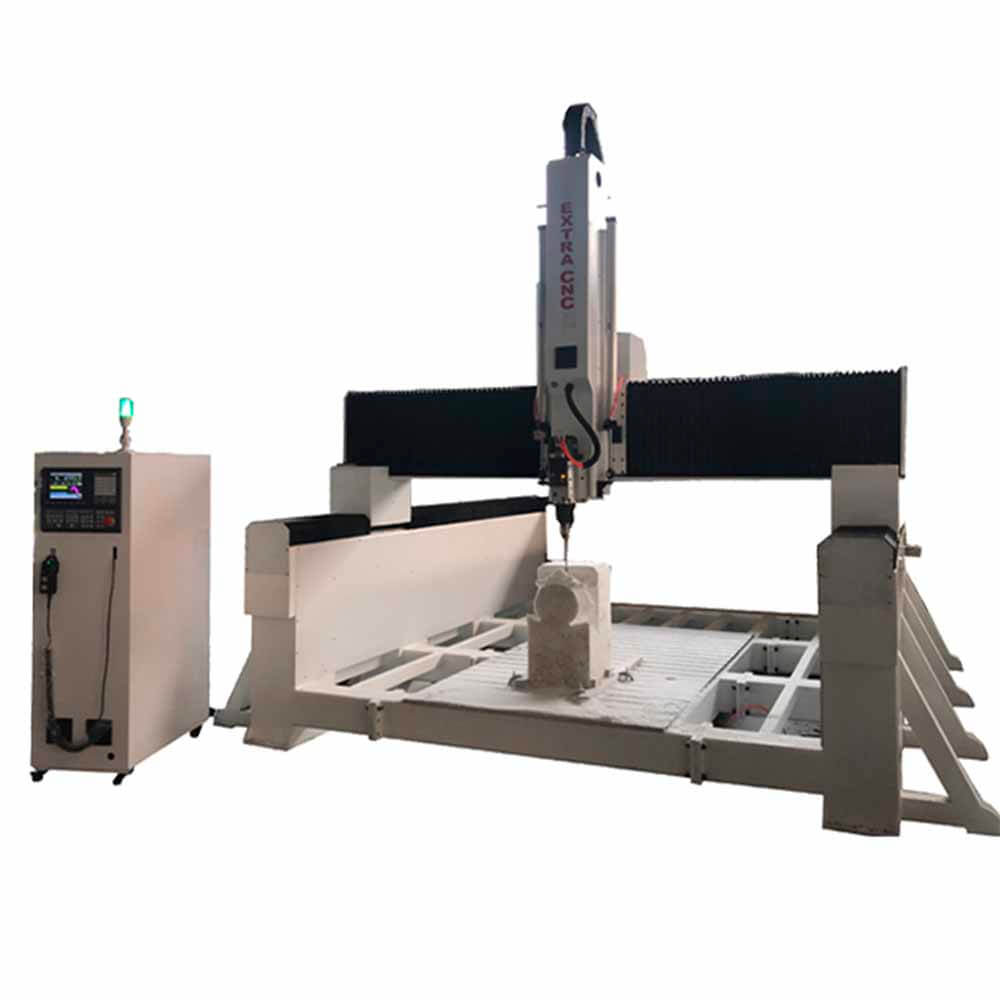

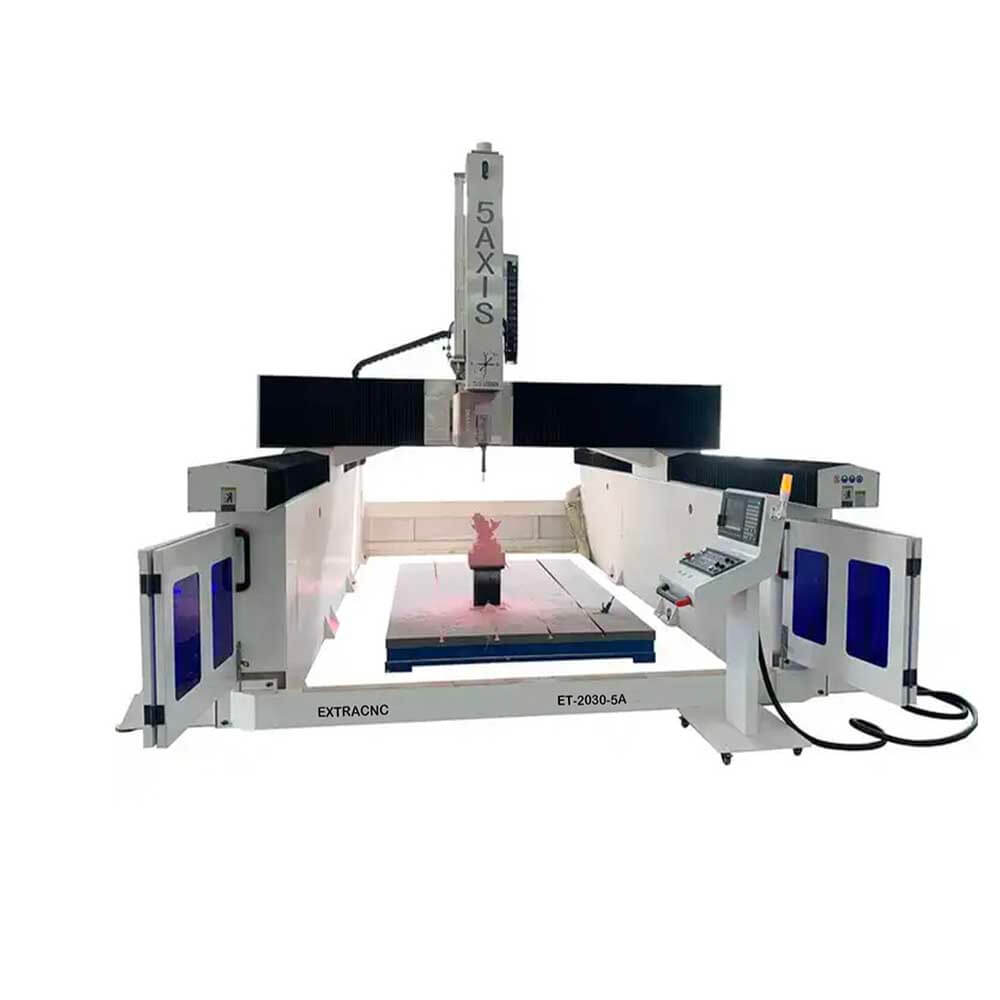

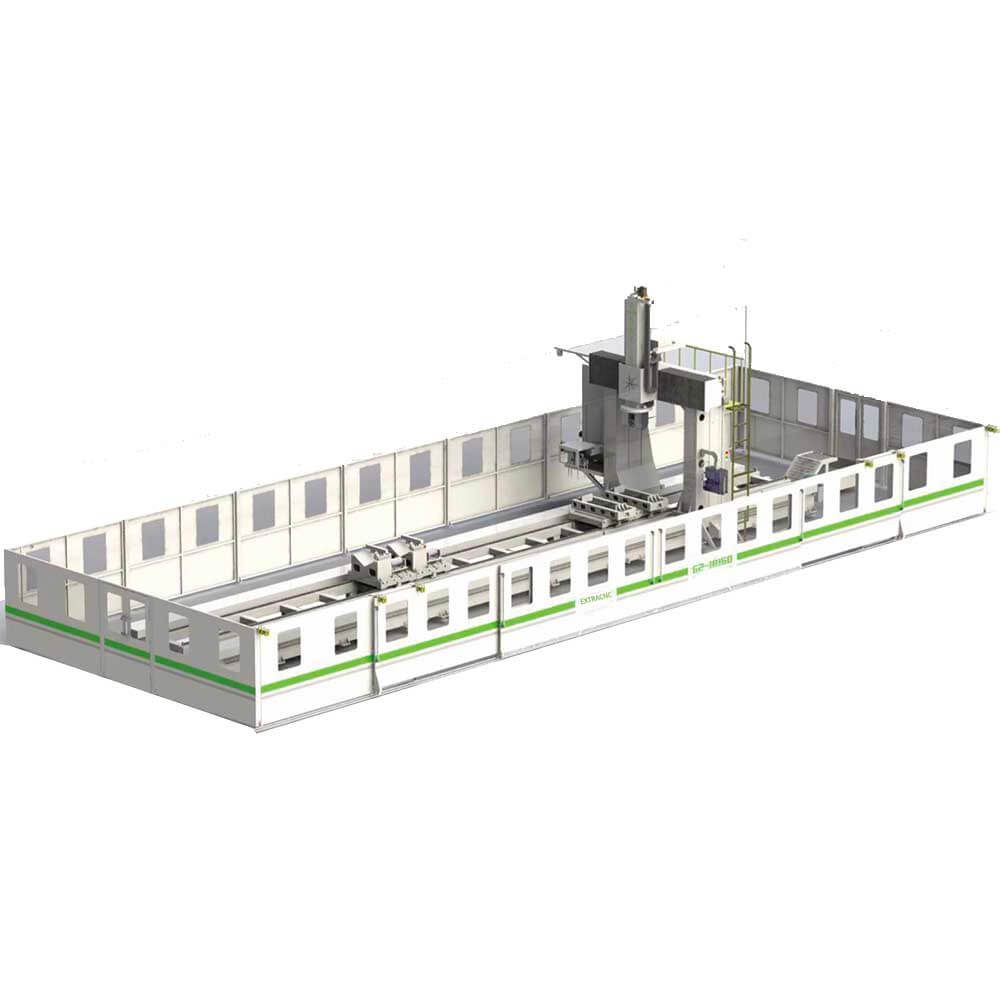

A Schuim/EPS CNC-freesmachine is een gespecialiseerde, computergestuurde snijmachine die is ontworpen voor het uiterst nauwkeurig bewerken van schuimmaterialen zoals EPS, XPS, polyurethaan en hardschuim. Het is een onmisbaar hulpmiddel in sectoren zoals bewegwijzering, beeldhouwkunst, verpakking, architectonische modellering en matrijzenbouw. Deze geavanceerde CNC-freesmachine wordt veel gebruikt door modelbouwers, signmakers, rekwisietfabrikanten en verpakkingsfabrikanten en biedt soepel en nauwkeurig snijden, snijden en vormen van zowel 2D- als complexe 3D-ontwerpen met een hoge herhaalbaarheid. Dankzij de lange Z-asverplaatsing, krachtige spindelmotoren en naadloze CAD/CAM-software-integratie zijn Foam/EPS CNC-freesmachines ideaal voor het leveren van gedetailleerde schaalmodellen, opvallende reclamedisplays, grootschalige rekwisieten, mallen op maat en beschermende verpakkingsoplossingen. Hun belang is sinds het begin van de jaren 2000 toegenomen, samen met de vraag naar lichtgewicht, kosteneffectieve materialen en nauwkeurige digitale fabricage, met voordelen zoals minder handmatige arbeid, minimaal materiaalverlies en een verbeterde productie-efficiëntie. Of het nu gaat om architectonische prototypes, artistieke sculpturen of industriële schuimcomponenten, een Foam/EPS CNC-router garandeert uitstekende kwaliteit, consistente nauwkeurigheid en betrouwbare prestaties. Daarmee is het een slimme investering voor bedrijven die de schuimverwerking willen stroomlijnen met professionele resultaten.

A Schuim/EPS CNC-freesmachine is een gespecialiseerde computergestuurde snijmachine die is ontworpen voor uiterst precieze bewerking van schuimmaterialen, waaronder geëxpandeerd polystyreen (EPS), polyurethaan en hardschuim. Deze geavanceerde CNC-oplossing wordt veel gebruikt in sectoren zoals bewegwijzering, beeldhouwkunst, verpakking, architectuurmodellering en matrijzenbouw en biedt ongeëvenaarde efficiëntie en nauwkeurigheid voor zowel prototyping als massaproductie.

Wie gebruikt een schuim-/EPS-CNC-freesmachine?

Schuim/EPS CNC-freesmachines worden gebruikt door professionals in diverse sectoren, zoals bouwers van architectonische modellen, reclameborden, rekwisietenfabrikanten, verpakkingsfabrikanten en fabrikanten van maatwerkmallen. Of u nu grootschalige reclamedisplays of gedetailleerde industriële mallen maakt, deze machine biedt de precisie en veelzijdigheid om te voldoen aan de specifieke eisen van de verwerking van schuimmateriaal.

Wat is een schuim/EPS CNC-router?

A Schuim/EPS CNC-freesmachine is een krachtige, computergestuurde machine die is ontworpen voor het snijden, kerven en vormen van lichtgewicht en poreuze materialen zoals EPS en hardschuim. Deze freesmachines zijn doorgaans uitgerust met een lange Z-as, krachtige maar soepele spindelmotoren en geavanceerde softwarecompatibiliteit, waardoor complexe 2D- en 3D-vormen naadloos kunnen worden uitgevoerd met een hoge herhaalbaarheid en fijne details.

Waar wordt een schuim/EPS CNC-freesmachine gebruikt?

Dit type CNC-freesmachine wordt veel gebruikt in:

Workshops over architectonische modellen voor het maken van gedetailleerde schaalmodellen.

Reclame- en bewegwijzeringsbedrijven voor het produceren van 3D-letters, logo's en displays.

Afdelingen theater- en filmrekwisieten voor het maken van grote rekwisieten en decors.

Fabrikanten van verpakkingen en isolatie Voor het snijden van schuimrubberen inzetstukken en beschermkappen.

Winkels voor op maat gemaakte mallen voor het maken van meesterpatronen en prototypes.

Sinds wanneer zijn CNC-freesmachines voor schuim/EPS essentieel?

Met de stijgende vraag naar lichtgewicht, aanpasbare en kosteneffectieve materialen in sectoren zoals de bouw, reclame en productie, Schuim/EPS CNC-freesmachines werden essentiële hulpmiddelen tijdens de uitbreiding van digitale fabricage in het begin van de jaren 2000. Hun vermogen om consistente kwaliteit en complexe 3D-vormen te leveren, versnelde hun toepassing in zowel creatieve als industriële toepassingen.

Waarom is een schuim/EPS CNC-freesmachine belangrijk?

A Schuim/EPS CNC-freesmachine is cruciaal omdat het het volgende mogelijk maakt:

Precisie en complexiteit: Maakt zeer gedetailleerde 3D-snedes en maakt zachte, delicate materialen glad zonder ze te beschadigen.

Verhoogde efficiëntie: Vermindert de hoeveelheid handmatige arbeid aanzienlijk, versnelt de productietijd en minimaliseert materiaalverspilling.

Veelzijdige toepassingen: Geschikt voor een breed scala aan schuimsoorten, zoals EPS, XPS, polyurethaan, EPP en meer. Hierdoor is het ideaal voor zowel artistieke als industriële toepassingen.

Kosteneffectieve productie: Automatiseert het maken van mallen, rekwisieten, borden en verpakkingscomponenten, waardoor zowel de insteltijd als de kans op menselijke fouten worden verminderd.

Hoe werkt een schuim-/EPS-CNC-freesmachine?

Het proces begint met een digitaal ontwerp, gemaakt in CAD-software, dat vervolgens via CAM-programmering wordt omgezet in een gereedschapspad. Zodra het materiaal op het machinebed is bevestigd, Schuim/EPS CNC-freesmachine Volgt het geprogrammeerde pad en beweegt de spindel langs meerdere assen om het schuim in de gewenste vorm te snijden, te kerven of te frezen. Speciale aandacht wordt besteed aan de spindelsnelheid, de voedingssnelheid en de snijgereedschappen om strakke randen en een onberispelijke afwerking te garanderen zonder de lichtgewicht structuur van het schuim te beschadigen.

Kortom, een Schuim/EPS CNC-freesmachine is een essentieel hulpmiddel voor moderne digitale fabricage en biedt nauwkeurige, efficiënte en veelzijdige oplossingen voor het werken met schuimmaterialen. Of u nu architectonische prototypes, creatieve sculpturen of industriële verpakkingen produceert, deze CNC-machine is ontworpen om uw productiecapaciteit te verhogen en tegelijkertijd de hoogste nauwkeurigheid en consistentie te behouden.