Related Blogs

Explore the world of 5-axis CNC routers! Discover their precision, key features, and applications in woodworking and manufacturing. Get tips for choosing the right machine for your projects!

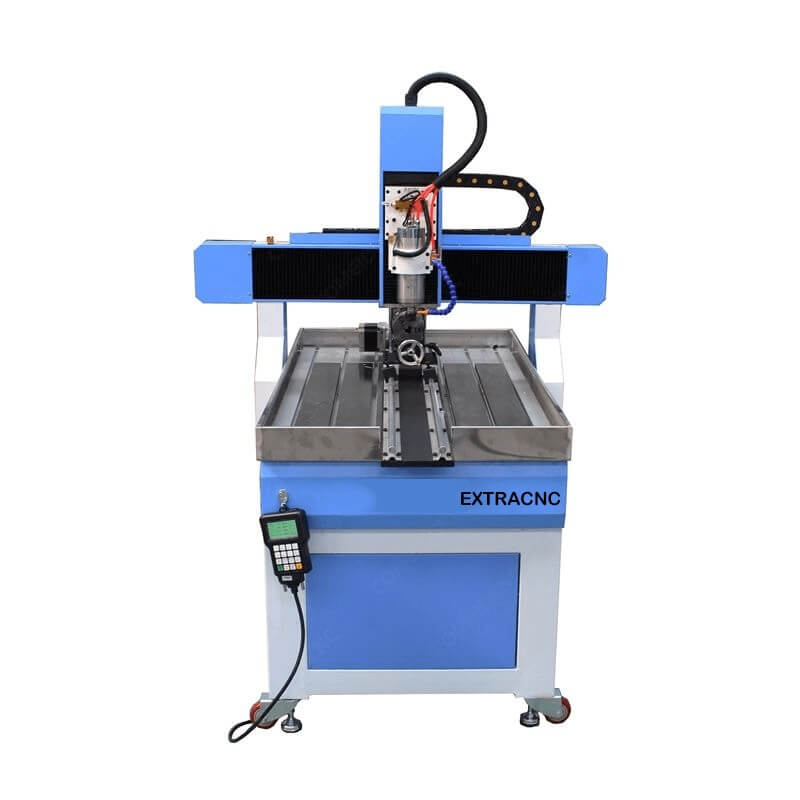

Enter the Mini CNC Milling Machine—a space-saving yet powerful solution perfect for workshops, schools, and small production facilities. Whether you’re looking for a CNC milling machine for metal or a versatile metal CNC router machine, this guide will help you understand your options and choose the right machine for your needs.

A mini CNC milling machine is a smaller version of a standard CNC mill, designed for precise cutting, drilling, and engraving operations—especially on metals. With a smaller footprint and user-friendly interface, it’s ideal for small-batch production, prototyping, and educational use.

Main Features:

A CNC milling machine for metal is engineered to deliver the high precision and torque needed to machine harder materials. These machines are built with reinforced frames, durable linear guides, and specialized cooling systems to manage the heat generated during metalworking.

Whether you’re crafting engine parts or metal molds, a CNC mill for metal ensures efficiency and consistent quality.

A metal CNC router machine often gets compared to milling machines. While both use similar technology, routers generally move faster and are better suited for softer materials. However, specially designed metal CNC router machines can also handle light metal tasks such as engraving aluminum sheets or cutting thin steel.

| Feature | CNC Milling Machine for Metal | Metal CNC Router Machine |

|---|---|---|

| Best for | Dense metals, complex parts | Thin metals, engraving |

| Speed | Slower, more torque | Faster, less torque |

| Spindle Power | 2.2kW–5.5kW | 1.5kW–3.0kW |

| Cooling Required | Yes (water/mist cooling) | Sometimes (optional) |

| Precision Level | Very high | Moderate to high |

When selecting your machine, consider:

Mini CNC milling machines and metal CNC routers are widely used in:

A Mini CNC Milling Machine, whether it’s used as a compact CNC milling machine for metal or a light-duty metal CNC router machine, can deliver remarkable precision and productivity. It’s a valuable asset for anyone needing accurate metal processing in a smaller format.

Explore the world of 5-axis CNC routers! Discover their precision, key features, and applications in woodworking and manufacturing. Get tips for choosing the right machine for your projects!

Send us your request for CNC machines and get an official price within 10 minutes!