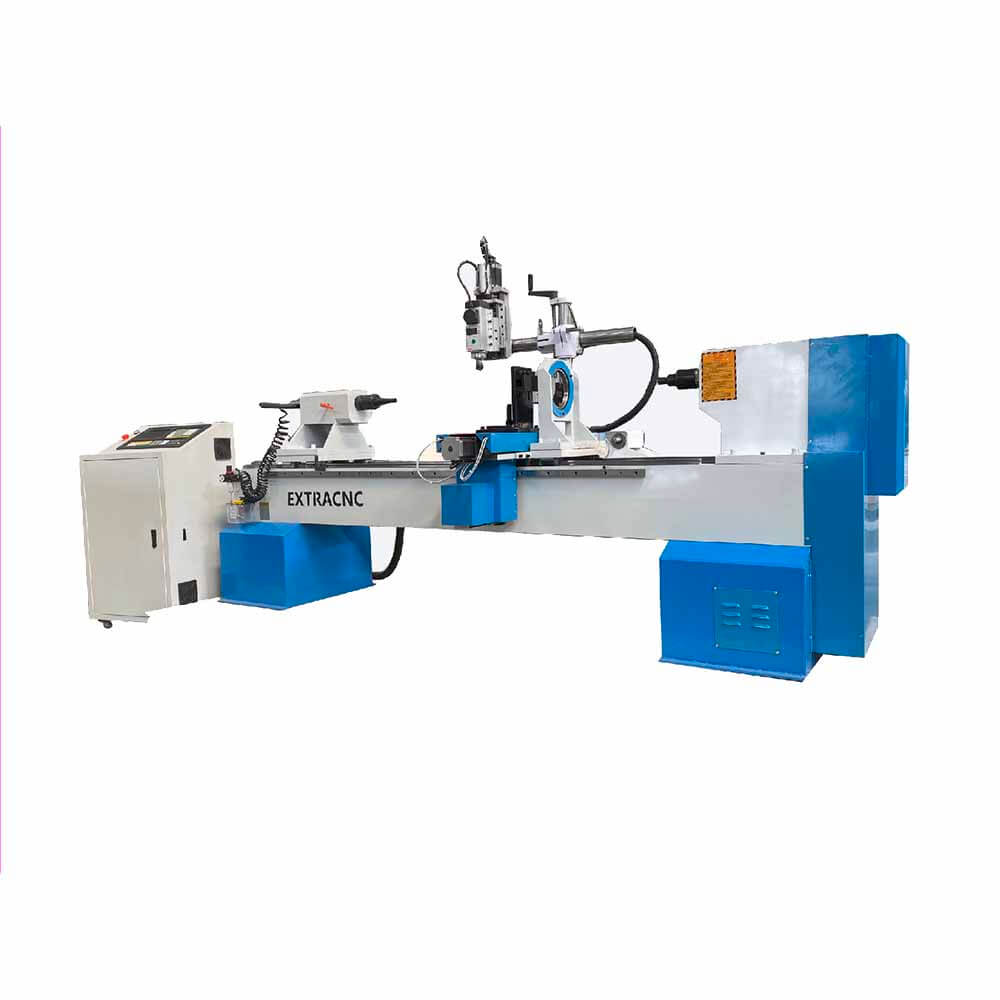

Tornio CNC per legno

UN Tornio CNC per legno È una macchina a controllo computerizzato progettata per la sagomatura e la lavorazione di materiali in legno con elevata precisione. Funziona ruotando il pezzo su un mandrino mentre un utensile da taglio viene applicato per rimuovere il materiale e creare la forma desiderata, come cilindrica, conica o motivi complessi. A differenza dei torni per legno tradizionali, i torni CNC per legno sono completamente automatizzati, consentendo tagli complessi e ripetibili senza intervento manuale. Sono dotati di funzionalità avanzate come un cambio utensile, un controllo preciso del mandrino e un software integrato per una facile programmazione e configurazione. Questi torni sono ideali per la produzione di componenti in legno come componenti per mobili, oggetti decorativi, mandrini e altri prodotti in legno di precisione. Grazie all'alta velocità e all'eccezionale precisione, i torni CNC per legno migliorano la produttività, riducono gli sprechi e offrono una qualità di finitura superiore, rendendoli uno strumento essenziale per l'industria della lavorazione del legno.

Tornio CNC per legno: precisione ed efficienza per la moderna lavorazione del legno

UN Tornio CNC per legno è uno strumento all'avanguardia che porta automazione, precisione e versatilità al processo di tornitura del legno. Combinando tecnologie avanzate Tecnologia CNC con alte prestazioni tornio, questo sistema automatizza le attività di modellatura, tornitura e intaglio del legno, consentendo ai falegnami di creare disegni intricati e prodotti di alta qualità con il minimo sforzo. Da produzione di mobili A tornitura artistica del legno E progetti di falegnameria personalizzatiI torni CNC per legno sono parte integrante di vari settori della lavorazione del legno.

Chi utilizza un tornio per legno CNC?

Torni CNC per legno sono utilizzati da una varietà di professionisti e settori, tra cui:

Produttori di mobili: Per creare dettagliati gambe di legno, fusi, E basi per tavoli con qualità e precisione costanti.

artigiani del legno:Per realizzare disegni intricati, pezzi di legno scultorei, E oggetti decorativi come ciotole, vasi e statue.

Tornitori in legno personalizzati: Per la produzione su misura prodotti in legno con forme, texture e finiture uniche.

Ebanisti: Per tornire alta qualità componenti del mobile ad esempio post, modanature, E ordinare.

Appassionati del fai da te e hobbisti: Per progetti personali di falegnameria che richiedono una tornitura di precisione.

Cos'è un tornio per legno CNC?

UN Tornio CNC per legno è un tornio controllato da computer Progettato specificamente per la tornitura e la sagomatura del legno con elevata precisione. A differenza dei tradizionali torni manuali per legno, il tornio CNC per legno è dotato di Controllori CNC che eseguono comandi pre-programmati per automatizzare il processo di tornitura. Questo permette all'operatore di concentrarsi sulla progettazione e sulla programmazione mentre la macchina si occupa del taglio, dell'intaglio e della sagomatura di precisione del legno.

La macchina opera lungo più assi (solitamente X, E, E Z) e utilizza il movimento rotatorio per intagliare e modellare il legno. Può creare un'ampia gamma di oggetti, da semplici forme cilindriche a motivi complessi e dettagliati.

Dove viene utilizzato?

I torni CNC per la tornitura del legno vengono utilizzati in numerose applicazioni e settori, tra cui:

Produzione di mobili: Creazione di contenuti coerenti e di alta qualità gambe di legno, balaustre, E componenti del mobile.

Tornitura artistica del legno: Per creare pezzi unici e scultorei, vasi, ciotolee altri oggetti ornamentali in legno.

Lavorazione del legno architettonica: Modellazione dettagliata colonne, modanature, E finiture in legno per progetti di interior design e costruzione.

Produzione di attrezzature sportive:Produzione di componenti quali mazze da hockey, mazze da baseball, E parti di strumenti musicali.

Modellismo: Realizzazione di modelli in legno precisi per prototipi e mostre.

Quando i torni CNC per la tornitura del legno sono diventati essenziali?

L'integrazione di Tecnologia CNC nel processo di tornitura del legno divenne significativo durante la fine del 20° secolo. Poiché la domanda di lavorazione del legno su misura, mobili pregiati, E produzione di massa di componenti complessi del legno aumentati, torni CNC per legno si sono affermate come strumenti essenziali per migliorare precisione, produttività ed efficienza. Queste macchine hanno permesso ai falegnami di replicare i progetti con una precisione e una coerenza ineguagliabili, riducendo il lavoro manuale e l'errore umano.

Perché è importante un tornio per legno CNC?

Precisione e accuratezza: I torni CNC per legno possono produrre forme estremamente dettagliate E dimensioni uniformi con elevata precisione. Questo è fondamentale per produzione di mobili E tornitura artistica del legno, dove coerenza e dettaglio sono essenziali.

Maggiore efficienza: L'automazione delle operazioni di tornitura del legno significa tempi di produzione più rapidi con tempi di fermo minimi. I torni CNC per legno possono lavorare in continuo, rendendoli ideali per entrambi produzione in piccoli lotti E produzione ad alto volume.

Flessibilità e versatilità:I torni per legno CNC sono estremamente versatili e in grado di creare un'ampia gamma di design, da forme cilindriche semplici A modelli complessi E elementi decorativiCiò li rende adatti a varie applicazioni, tra cui mobili su misura, lavorazione architettonica del legno, E progetti artistici.

Riduzione degli sprechi di materiale:I torni per legno CNC sono estremamente efficienti in termini di utilizzo dei materiali, poiché possono produrre parti con misure precise e sprechi minimi, il che li rende convenienti sia per i produttori su larga scala che per le piccole falegnamerie.

Personalizzazione: I torni per legno CNC consentono disegni personalizzati E modelli personalizzati, il che li rende una scelta eccellente per le aziende che offrono prodotti in legno su misura o pezzi unici nel loro genere.

Sicurezza migliorata:Poiché i torni per legno CNC sono completamente automatizzati, riducono la necessità di lavoro manuale e consentono agli operatori di lavorare da una distanza di sicurezza, riducendo al minimo il rischio di infortuni associato ai metodi tradizionali di tornitura del legno.

Come funziona un tornio per legno CNC?

Fase di progettazione:Il processo di tornitura del legno inizia con la creazione di un disegno digitale, in genere utilizzando CAD (progettazione assistita da computer) software. La progettazione può includere dettagli forme, modellie misurazioni.

Programmazione CAM: Il design viene importato in CAM (produzione assistita da computer) software, che genera i percorsi utensile necessari per la macchina CNC. Questo processo traduce il progetto in istruzioni per la macchina Controllore CNC.

Impostazione del materiale: Il pezzo in legno viene fissato sulla macchina mandrino rotante O mandrino, garantendo la stabilità durante il processo di tornitura. L'impostazione prevede anche la selezione degli utensili da taglio appropriati, come punte in carburo O frese diamantate.

Processo di tornitura: Guidato dal controllo CNC, il il mandrino ruota il pezzo in lavorazione mentre l'utensile da taglio si muove lungo più assi per modellare il legno. La macchina esegue operazioni come taglio grezzo, finitura, E intaglio di dettaglio, a seconda del design.

Operazioni di finitura: Dopo il completamento del processo di tornitura, potrebbe essere necessaria un'ulteriore post-elaborazione, come ad esempio levigatura, lucidatura, O sigillatura, per ottenere la finitura superficiale e la levigatezza desiderate.

Vantaggi di un tornio per legno CNC

Risultati di alta qualità: I torni CNC per la tornitura del legno offrono risultati costanti e di alta precisione, rendendoli ideali per produzione di massa O lavorazione del legno personalizzata progetti in cui l'attenzione ai dettagli è fondamentale.

Velocità ed efficienza: I torni CNC per legno possono funzionare in continuo, riducendo significativamente i tempi di produzione. I processi automatizzati garantiscono inoltre tempi di consegna più rapidi rispetto ai metodi manuali.

Gestione della complessità: Queste macchine possono creare geometrie complesse E modelli intricati, che sarebbe dispendioso in termini di tempo o impossibile da ottenere con i metodi tradizionali di tornitura del legno.

Risparmio sui costi:Riducendo gli sprechi di materiale, migliorando la velocità di produzione e riducendo al minimo i costi di manodopera, i torni CNC per legno offrono un elevato ritorno sull'investimento (ROI).

Funzionamento intuitivo:I moderni torni CNC per legno sono dotati di comandi intuitivi e interfacce touch-screen, che li rendono accessibili sia ai falegnami esperti che ai principianti.

Conclusione

UN Tornio CNC per legno è uno strumento fondamentale nella moderna lavorazione del legno, offrendo precisione, velocità e versatilità senza pari. Che tu stia producendo oggetti di alta qualità mobilia, intricato sculture in legno, o personalizzato progetti di tornitura del legnoIl tornio per legno CNC semplifica il processo di produzione e garantisce che ogni pezzo soddisfi i più elevati standard di artigianalità. Automatizzando il processo di tornitura, questa macchina consente ai falegnami di concentrarsi su creatività e innovazione, spingendo i confini del possibile nella lavorazione del legno.

Per le aziende che mirano ad aumentare la produttività, ridurre gli sprechi e ottenere risultati costanti e di alta qualità, investire in un tornio per legno CNC è una scelta intelligente che offre vantaggi a lungo termine.