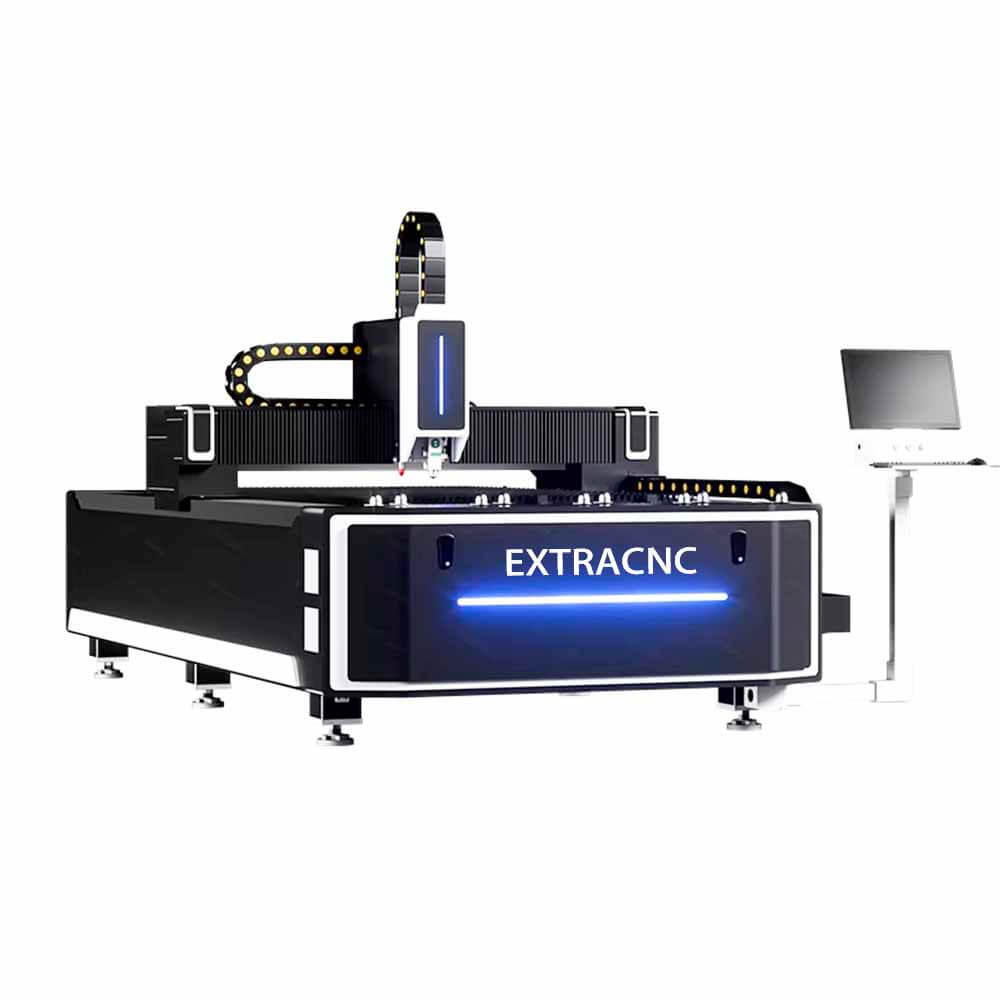

Le découpe laser à fibre automatique système est idéal pour les industries qui nécessitent une découpe précise de matériaux tels que acier au carbone, aluminium, cuivre, et acier inoxydableIl est largement utilisé dans fabrication métallique, production de pièces automobiles, fabrication de machines, signalisation publicitaire, composants électriques, et ustensiles de cuisineCe système améliore l’efficacité de la production, réduit les coûts de main-d’œuvre et garantit des coupes précises et de haute qualité pour une variété de matériaux métalliques.