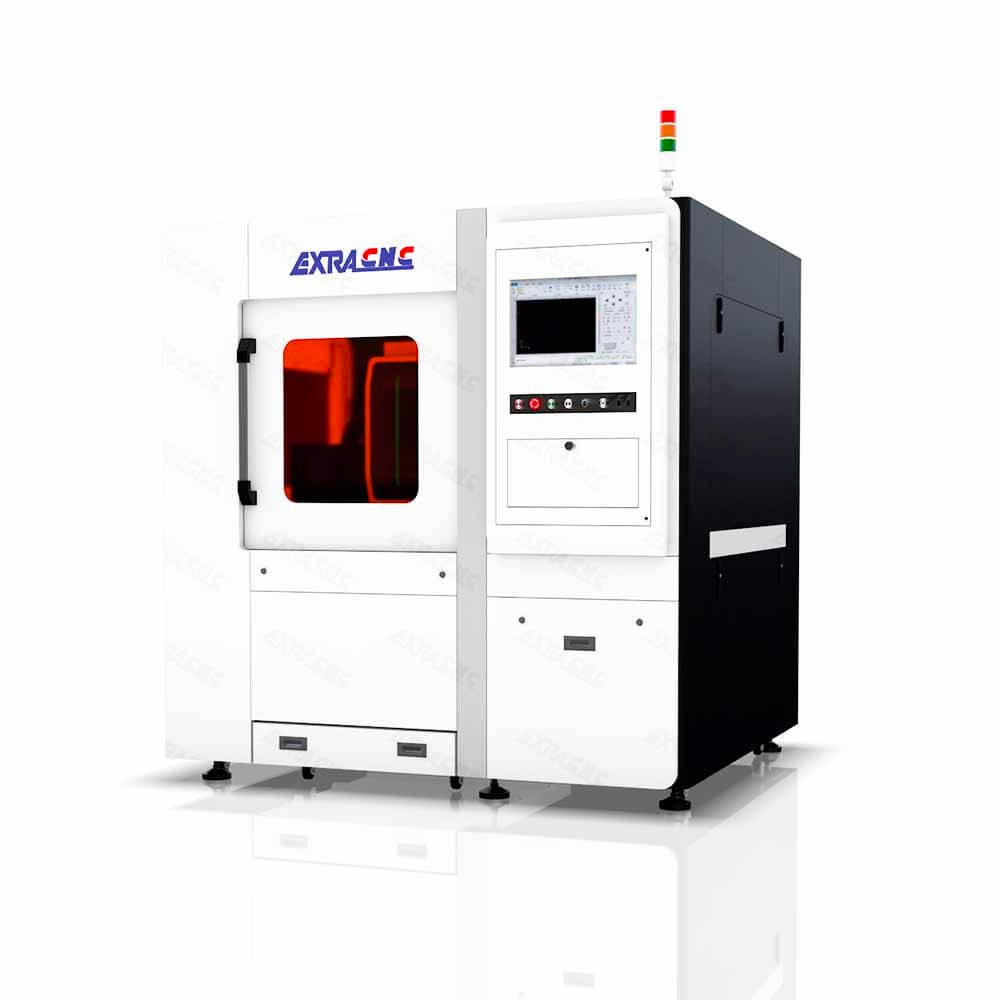

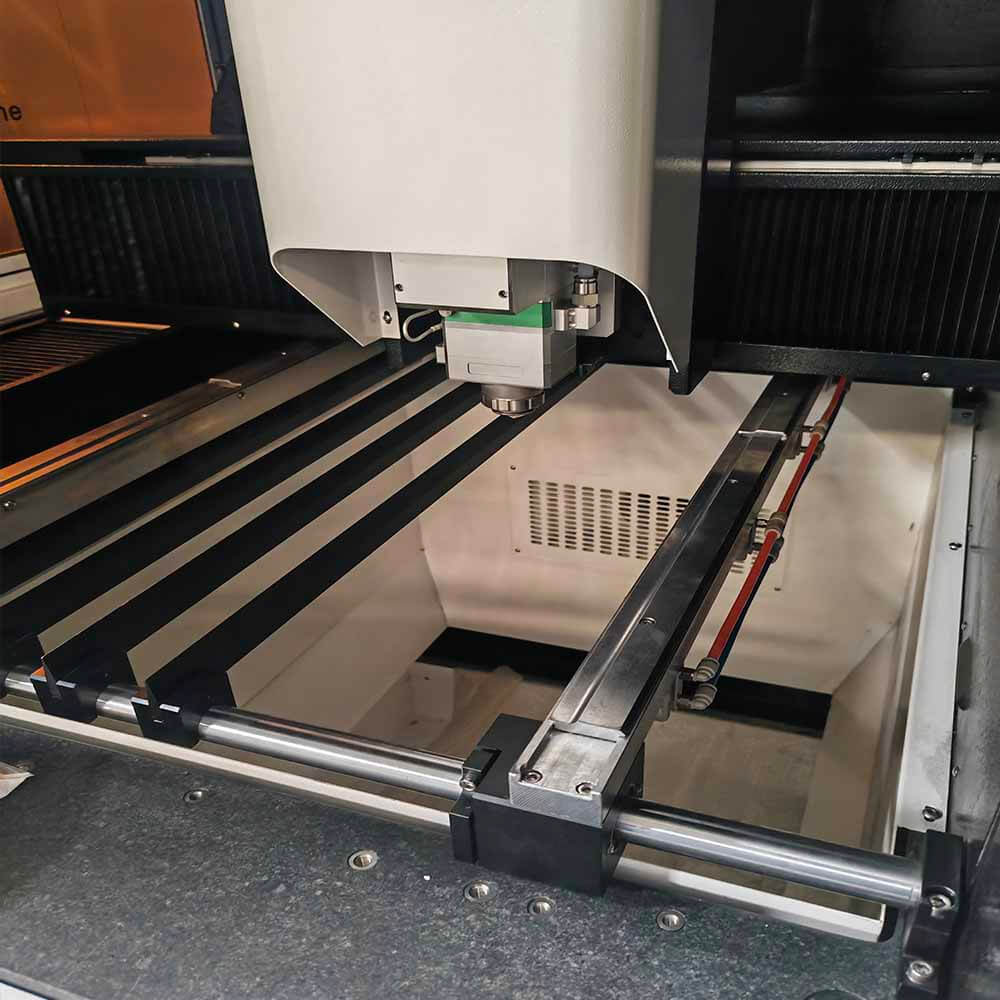

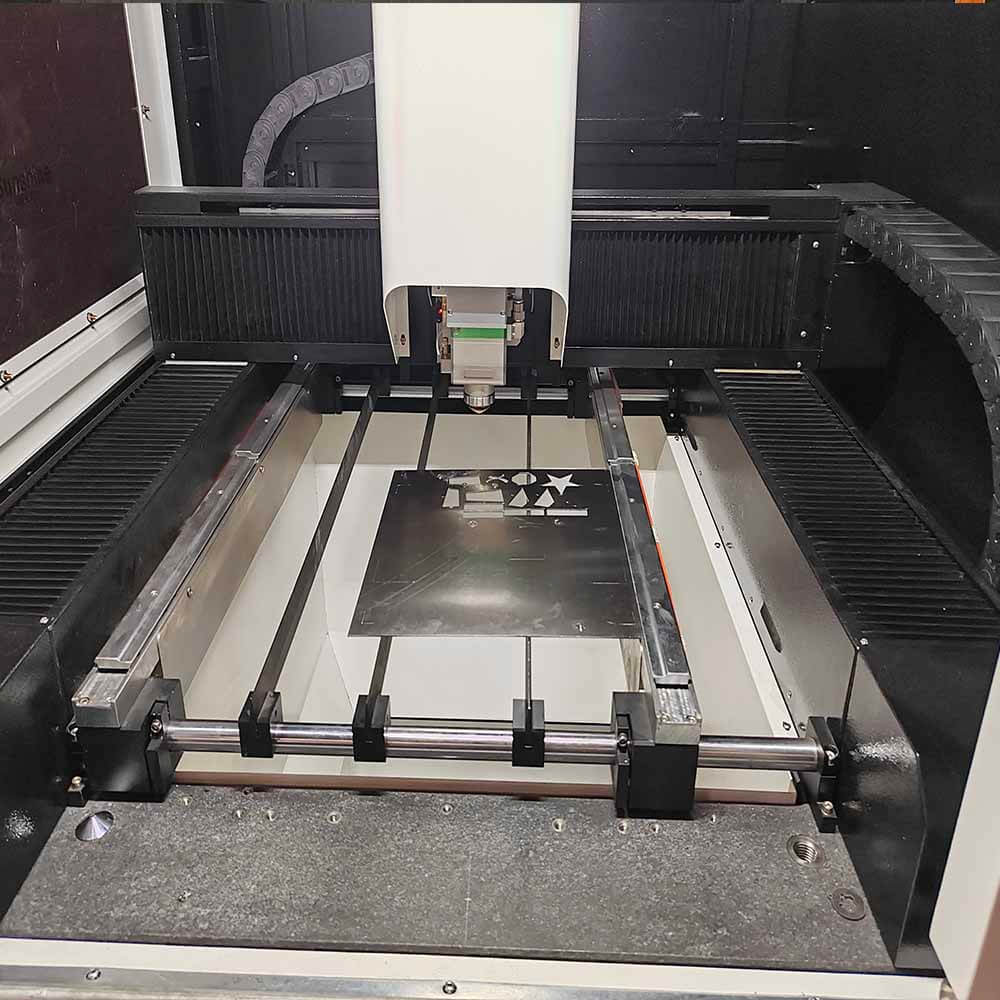

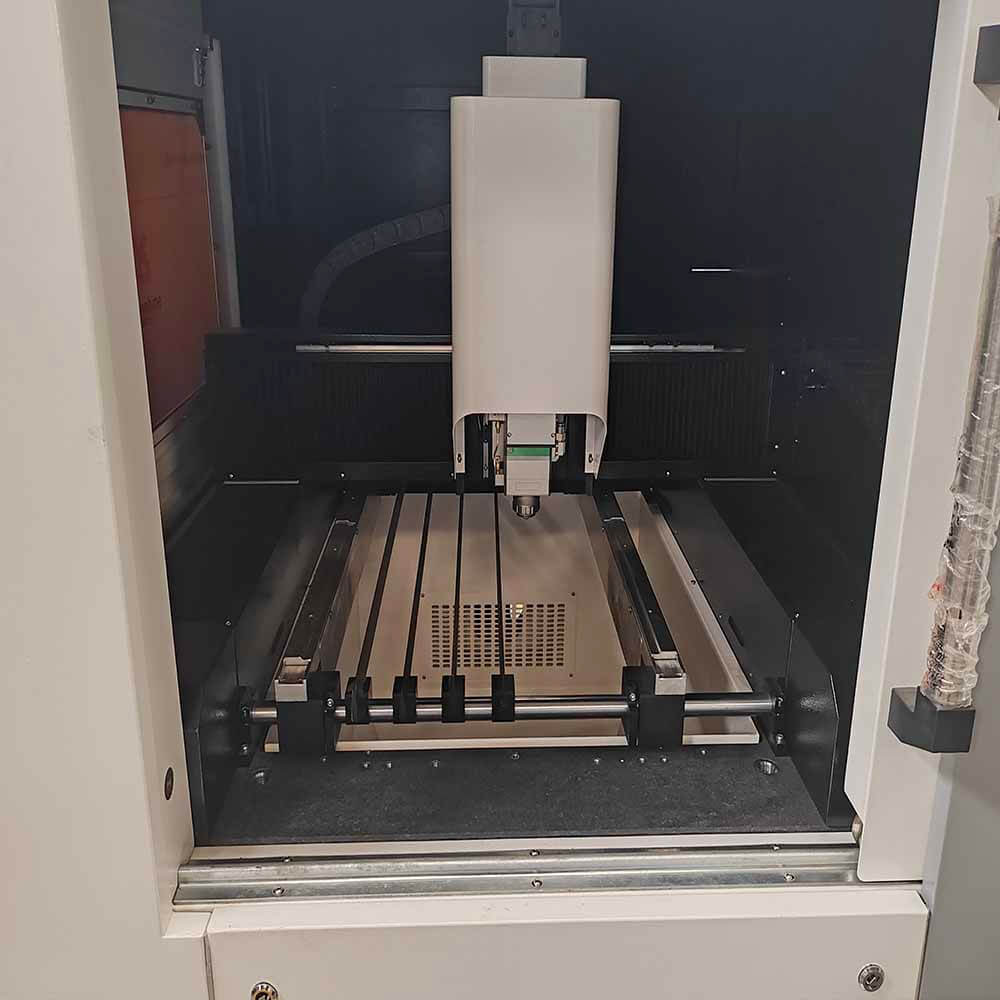

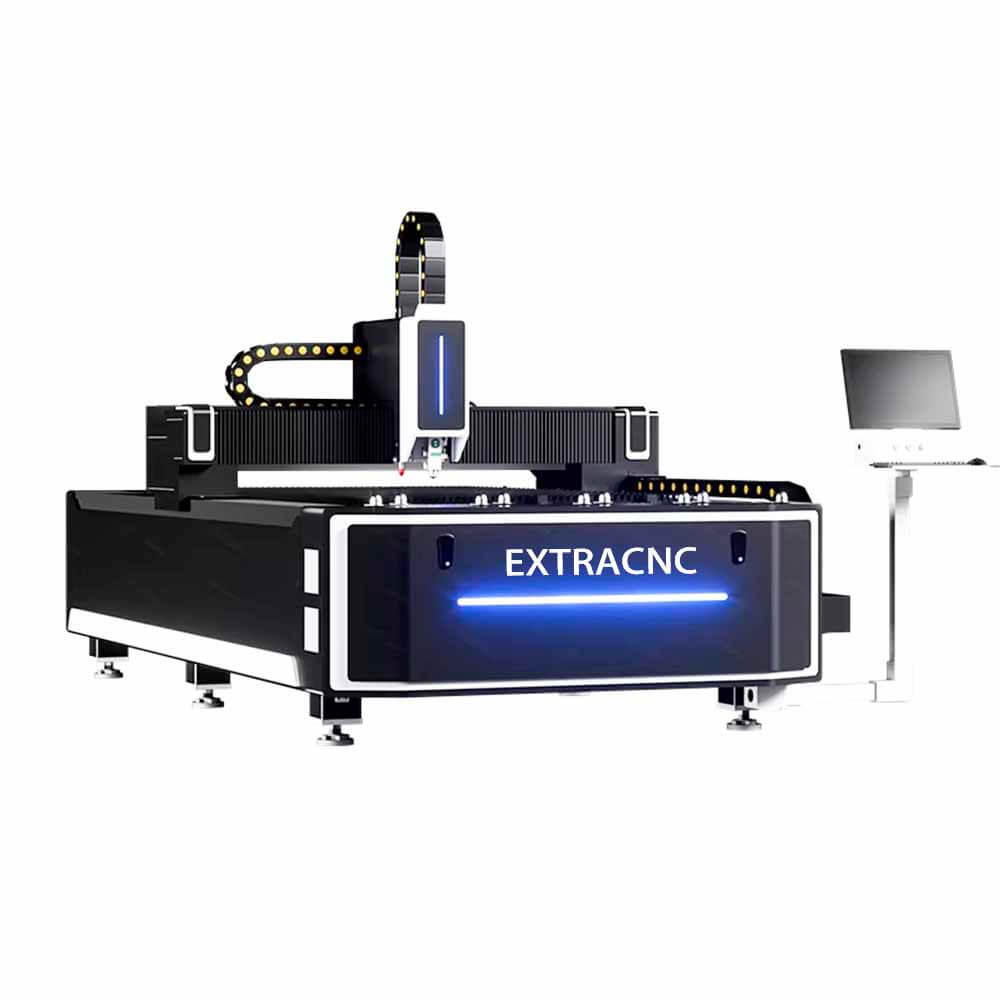

El Cortadora láser de fibra asequible ofertas corte de alta precisión para acero al carbono, acero inoxidable, aluminio, cobre, latón, titanio y otros metales delgados. Con tecnología avanzada de láser de fibra, asegura Bordes suaves, eficiencia y rendimiento rentable, lo que lo hace ideal para industrias de fabricación de metales.