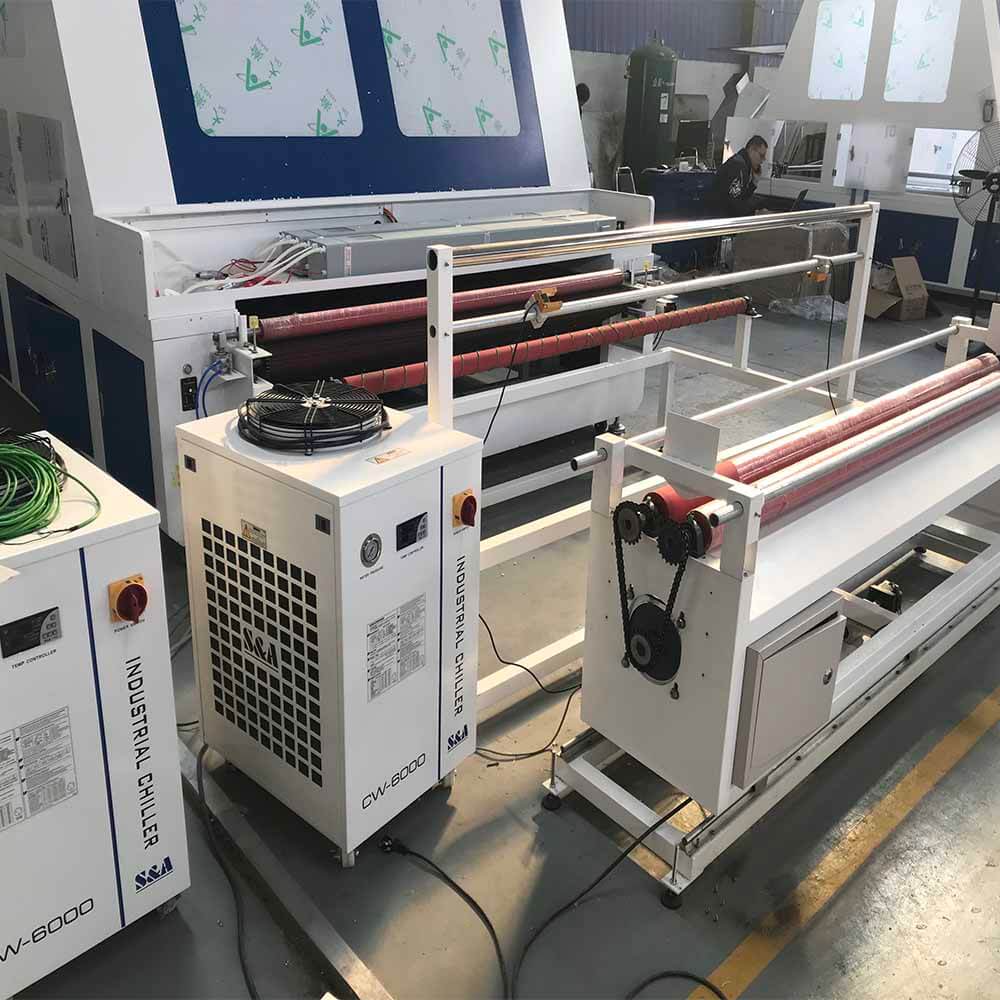

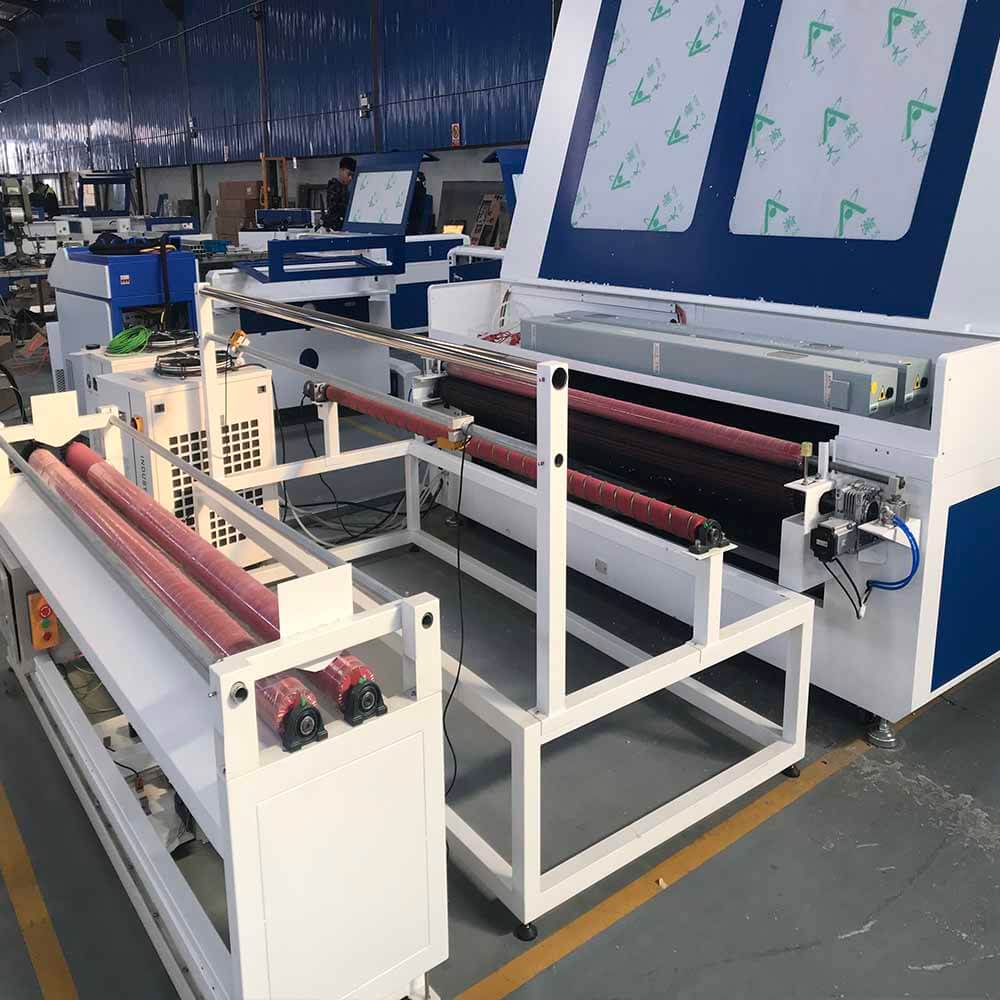

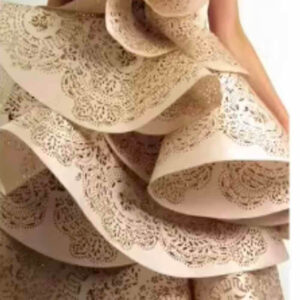

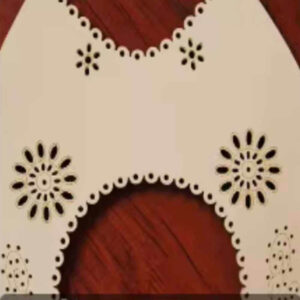

Αυτό το μηχάνημα χρησιμοποιείται ευρέως στις βιομηχανίες εσωτερικού αυτοκινήτου, κλωστοϋφαντουργίας, αποσκευών και οικιακής επίπλωσης. Προσφέρει κοπή υψηλής ακρίβειας για μια ποικιλία υλικών, όπως μαξιλάρια καθισμάτων, καλύμματα καθισμάτων, πατάκια αυτοκινήτου, συνθετικό δέρμα, EVA και σύνθετα υφάσματα. Ιδανικό για την παραγωγή ταπετσαριών αυτοκινήτων, πατακιών δαπέδου και διακοσμητικών ενθέτων, και επίσης υπερέχει στην κοπή υφασμάτων για ρούχα σκι, μαγιό, προστατευτικό εξοπλισμό, καναπέδες, κουρτίνες, σκηνές και άλλα μαλακά έπιπλα. Η ευελιξία και η ακρίβειά του το καθιστούν ένα πολύτιμο εργαλείο για τους κατασκευαστές που αναζητούν αποτελεσματικές και συνεπείς λύσεις κοπής.