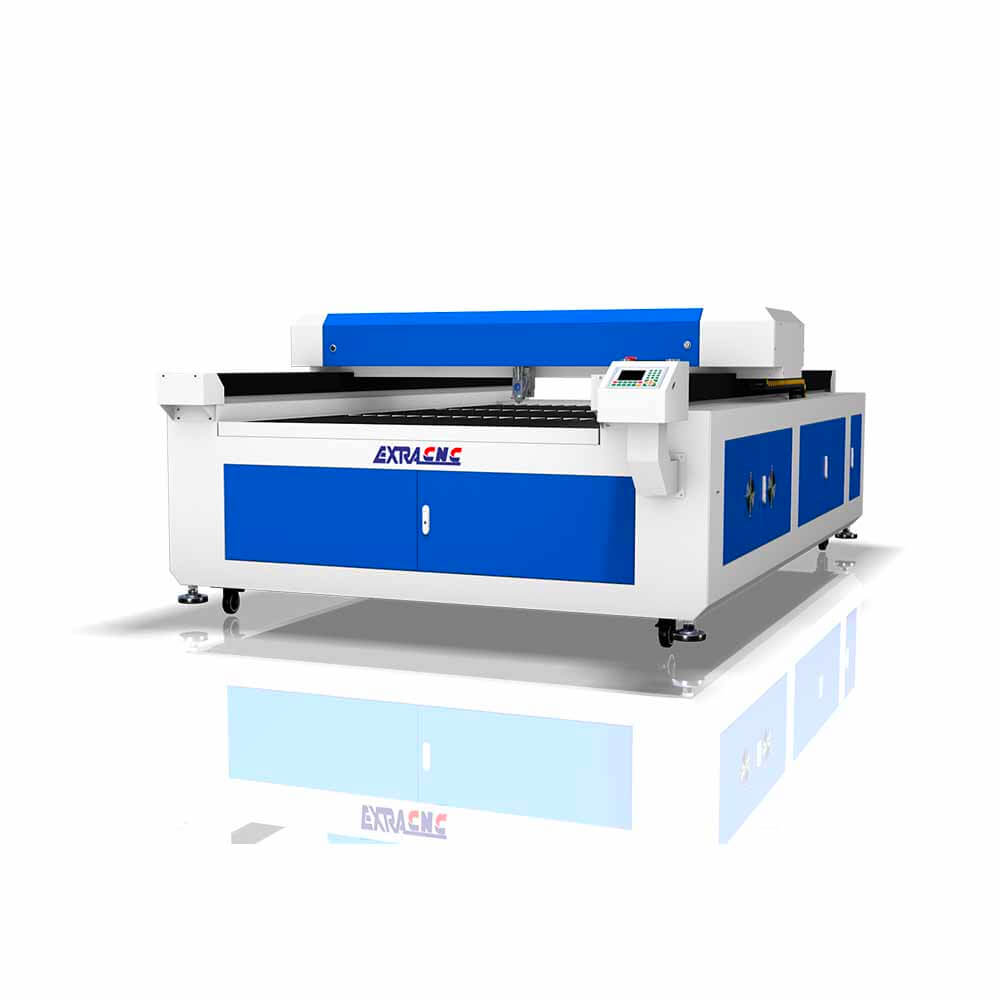

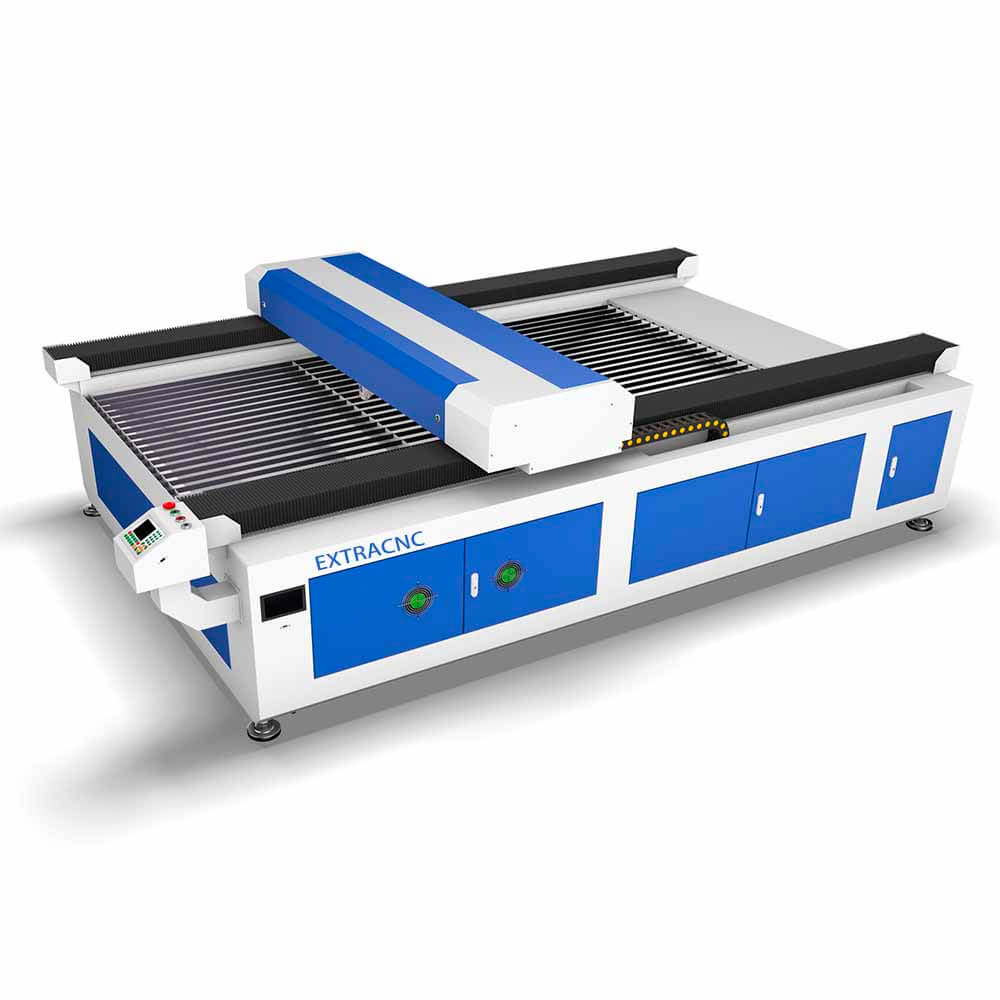

Μικτή μηχανή κοπής λέιζερ

ΕΝΑ Μικτή μηχανή κοπής λέιζερ Συνδυάζει τις δυνατότητες των τεχνολογιών λέιζερ οπτικών ινών και CO2, προσφέροντας μεγαλύτερη ευελιξία και αποτελεσματικότητα στην κοπή μιας ευρείας ποικιλίας υλικών. Αυτός ο τύπος μηχανής κοπής λέιζερ επιτρέπει βέλτιστη απόδοση κοπής σε μέταλλα, πλαστικά, ξύλο και άλλα υλικά, εναλλάσσοντας μεταξύ λέιζερ οπτικών ινών και CO2 ανάλογα με το υλικό και το πάχος. Το λέιζερ οπτικών ινών παρέχει κοπές υψηλής ταχύτητας και υψηλής ακρίβειας σε μέταλλα όπως χάλυβας και αλουμίνιο, ενώ το λέιζερ CO2 είναι ιδανικό για την κοπή μη μετάλλων όπως ξύλο, ακρυλικό και κεραμικά. Ενσωματώνοντας και τις δύο τεχνολογίες, οι μηχανές κοπής μικτών λέιζερ μπορούν να χειριστούν πιο ποικίλες εργασίες, βελτιώνοντας την παραγωγικότητα και μειώνοντας την ανάγκη για πολλαπλές μηχανές. Αυτές οι μηχανές χρησιμοποιούνται συνήθως σε βιομηχανίες όπως η αυτοκινητοβιομηχανία, η αεροδιαστημική, η σήμανση και η κατασκευή, όπου η ευελιξία, η ακρίβεια και η αποτελεσματικότητα είναι απαραίτητες για παραγωγή υψηλής ποιότητας.

Μηχανή κοπής μεικτών λέιζερ: Μια ευέλικτη λύση για κοπή ακριβείας

Ο Μικτή μηχανή κοπής λέιζερ είναι μια καινοτόμος λύση σχεδιασμένη να συνδυάζει διαφορετικές τεχνολογίες λέιζερ, όπως κοπή με λέιζερ ινών και Κοπή με λέιζερ CO2, σε ένα ενιαίο σύστημα. Αυτή η ευέλικτη μηχανή κοπής μπορεί να χειριστεί ένα ευρύ φάσμα υλικών, όπως μέταλλα, πλαστικά, ξύλο, ακόμη και γυαλί, προσφέροντας εξαιρετική ακρίβεια και ταχύτητα σε διάφορους κλάδους. Με την ικανότητά της να εναλλάσσεται μεταξύ διαφορετικών πηγών λέιζερ ανάλογα με το υλικό που υποβάλλεται σε επεξεργασία, το μικτή μηχανή κοπής λέιζερ αποτελεί ιδανική επιλογή για επιχειρήσεις που αναζητούν υψηλή ευελιξία και αποτελεσματικότητα στις εργασίες κοπής τους.

Ποιος χρησιμοποιεί μια μηχανή κοπής μεικτού λέιζερ;

Ο Μικτή μηχανή κοπής λέιζερ χρησιμοποιείται από βιομηχανίες που απαιτούν ευέλικτες και αποτελεσματικές λύσεις κοπής για διαφορετικά υλικά. Οι βασικοί τομείς περιλαμβάνουν:

Μεταλλικές κατασκευέςΓια κοπή μετάλλων όπως ανοξείδωτο ατσάλι, ανθρακούχος χάλυβας, αλουμίνιο, και ορείχαλκος.

Επιχειρήσεις κατασκευής πινακίδωνΓια κοπή και χάραξη πινακίδων κατασκευασμένων από μια ποικιλία υλικών, συμπεριλαμβανομένων μετάλλων και πλαστικών.

Αυτοκινητοβιομηχανίες και αεροδιαστημικές βιομηχανίεςΓια ακριβή κοπή μετάλλου και κατασκευή εξαρτημάτων κατά παραγγελία.

Κατασκευή επίπλωνΓια κοπή και χάραξη ξύλινων και μεταλλικών εξαρτημάτων κατά τη δημιουργία επίπλων κατά παραγγελία.

Βιομηχανία ηλεκτρονικών ειδώνΓια ακριβή κοπή πλακετών και εξαρτημάτων PCB.

Βιομηχανίες τέχνης και γλυπτικήςΓια τη δημιουργία περίπλοκων σχεδίων και γλυπτών από μια ποικιλία υλικών, όπως ξύλο και μέταλλο.

Τι είναι μια μηχανή κοπής μεικτού λέιζερ;

ΕΝΑ Μικτή μηχανή κοπής λέιζερ συνδυάζει δύο ή περισσότερες τεχνολογίες λέιζερ, συνήθως λέιζερ οπτικών ινών και Λέιζερ CO2, σε ένα μηχάνημα. Αυτό επιτρέπει απρόσκοπτες μεταβάσεις μεταξύ διαφορετικών τύπων λέιζερ ανάλογα με το υλικό και την εφαρμογή. Τα λέιζερ οπτικών ινών είναι ιδανικά για την κοπή μετάλλων, ενώ Λέιζερ CO2 διαπρέπουν στην κοπή μη μεταλλικών υλικών όπως ξύλο, πλαστικά είδη, και ακρυλικόΣυνδυάζοντας και τους δύο τύπους λέιζερ, το μικτή μηχανή κοπής λέιζερ προσφέρει απαράμιλλη ευελιξία για επιχειρήσεις που εργάζονται με ένα ευρύ φάσμα υλικών.

Το μηχάνημα λειτουργεί χρησιμοποιώντας ένα σύστημα CNC (Computer Numerical Control - Αριθμητικός Έλεγχος Υπολογιστή) που ελέγχει με ακρίβεια την κίνηση του λέιζερ κατά μήκος πολλαπλών αξόνων (συνήθως X, Y και Z). Αυτό το σύστημα διασφαλίζει ότι το λέιζερ μπορεί να κόβει περίπλοκα σχέδια και μοτίβα με υψηλή ακρίβεια.

Πού χρησιμοποιούνται οι μικτές μηχανές κοπής με λέιζερ;

Μηχανές κοπής με λέιζερ μικτών διαστάσεων χρησιμοποιούνται σε διάφορους κλάδους όπου απαιτείται κοπή ακριβείας και ευελιξία. Αυτές περιλαμβάνουν:

Κατασκευή μετάλλου και λαμαρίνας: Κοπή μεταλλικά φύλλα για δομικά στοιχεία και εξαρτήματα εξοπλισμού.

Ξυλουργικές εργασίες και ντουλάπιαΧάραξη και κοπή ξύλινων εξαρτημάτων επίπλων, πινακίδων και διακοσμητικών στοιχείων.

Κοπή πλαστικού και ακρυλικούΓια τη δημιουργία εξαρτημάτων ακριβείας κοπής για βιτρίνες, πινακίδες και συσκευασίες.

Κλωστοϋφαντουργικές και βιομηχανίες μόδαςΚοπή υφασμάτων και υφασμάτων για ενδύματα και αξεσουάρ.

Τέχνη και γλυπτικήΓια κοπή και χάραξη περίπλοκων σχεδίων σε διάφορα υλικά όπως ξύλο, μέταλλο και γυαλί.

Πότε απέκτησαν δημοτικότητα οι μικτές μηχανές κοπής με λέιζερ;

Η ιδέα του συνδυασμού διαφορετικών τεχνολογιών λέιζερ σε ένα μηχάνημα κέρδισε δημοτικότητα τη δεκαετία του 2000, καθώς οι κατασκευαστές αναζητούσαν τρόπους για να βελτιώσουν την ευελιξία και να αυξήσουν την παραγωγικότητα. Η εισαγωγή του μηχανές κοπής με λέιζερ ινών έφερε επανάσταση στον κλάδο προσφέροντας ταχύτερες ταχύτητες κοπής και μεγαλύτερη απόδοση, ιδιαίτερα για κοπή μετάλλου. Λέιζερ CO2, από την άλλη πλευρά, έχουν προτιμηθεί εδώ και καιρό για την κοπή μη μετάλλων. μικτή μηχανή κοπής λέιζερ αναδείχθηκε ως μια λύση για τον συνδυασμό αυτών των δύο τεχνολογιών, προσφέροντας στις βιομηχανίες τα καλύτερα και των δύο κόσμων.

Γιατί είναι σημαντική μια μηχανή κοπής μεικτού λέιζερ;

Βελτιωμένη ευελιξία: Η δυνατότητα εναλλαγής μεταξύ λέιζερ οπτικών ινών για κοπή μετάλλου και Λέιζερ CO2 Η χρήση μη μετάλλων καθιστά τη μηχανή κοπής μεικτών λέιζερ ένα απίστευτα ευέλικτο εργαλείο. Επιτρέπει στους κατασκευαστές να εργάζονται με μια μεγάλη ποικιλία υλικών χρησιμοποιώντας ένα μηχάνημα, βελτιώνοντας την απόδοση και μειώνοντας την ανάγκη για πολλαπλές μηχανές.

Αυξημένη Αποδοτικότητα: Με ένα μικτή μηχανή κοπής λέιζερ, οι κατασκευαστές μπορούν να βελτιστοποιήσουν τις διαδικασίες κοπής τους, να μειώσουν τους χρόνους εγκατάστασης και να βελτιστοποιήσουν τις ροές εργασίας παραγωγής. Η ικανότητα του μηχανήματος να χειρίζεται πολλαπλά υλικά με ελάχιστες προσαρμογές βοηθά στην επιτάχυνση της παραγωγής.

Υψηλή ακρίβεια και ποιότηταΤο μηχάνημα προσφέρει κοπές υψηλής ποιότητας με ελάχιστη παραμόρφωση, καθιστώντας το ιδανικό για βιομηχανίες που απαιτούν ακρίβεια, όπως π.χ. αυτοκινητοβιομηχανία και αεροδιαστημική βιομηχανίες.

Οικονομική αποδοτικότηταΕξαλείφοντας την ανάγκη για ξεχωριστά μηχανήματα για διαφορετικά υλικά, οι επιχειρήσεις μπορούν να μειώσουν τις κεφαλαιουχικές τους επενδύσεις και το λειτουργικό κόστος. μικτή μηχανή κοπής λέιζερ μειώνει επίσης τη σπατάλη υλικών παρέχοντας ακριβείς κοπές, συμβάλλοντας στην εξοικονόμηση κόστους.

Ευέλικτη εφαρμογή: Από μεταλλική κατασκευή να ξυλουργική και πλαστικά είδη, η μηχανή κοπής μεικτού λέιζερ μπορεί να χειριστεί ένα ευρύ φάσμα υλικών και εφαρμογών, καθιστώντας την μια εξαιρετική λύση για βιομηχανίες με ποικίλες ανάγκες κοπής.

Πώς λειτουργεί μια μηχανή κοπής μεικτού λέιζερ;

Φάση Σχεδιασμού: Η διαδικασία ξεκινά με ένα σχέδιο που δημιουργείται χρησιμοποιώντας CAD (Σχεδίαση με τη βοήθεια υπολογιστή) λογισμικό. Στη συνέχεια, το σχέδιο εισάγεται στο CAM (Υποβοηθούμενη από Υπολογιστή Κατασκευή) Λογισμικό για τη δημιουργία οδηγιών κοπής.

Επιλογή λέιζερ: Το Ελεγκτής CNC επιλέγει τον κατάλληλο τύπο λέιζερ με βάση το υλικό που κόβεται. Λέιζερ οπτικών ινών χρησιμοποιούνται για μέταλλα, ενώ Λέιζερ CO2 Χρησιμοποιούνται για μη μέταλλα όπως ξύλο, πλαστικό και ακρυλικό.

Ρύθμιση ΥλικούΤο υλικό που πρόκειται να κοπεί τοποθετείται στην πλατφόρμα κοπής και το σύστημα διασφαλίζει την σωστή ευθυγράμμιση και την ασφαλή στερέωση, συχνά χρησιμοποιώντας ένα τραπέζι κενού ή σύστημα σύσφιξης.

Διαδικασία κοπής με λέιζερΗ δέσμη λέιζερ εστιάζεται στο υλικό, όπου είτε λιώνει, είτε καίγεται, είτε εξατμίζεται, ανάλογα με τον τύπο του λέιζερ. Σύστημα CNC κινεί την κεφαλή λέιζερ κατά μήκος των προγραμματισμένων διαδρομών κοπής με υψηλή ακρίβεια.

Μετα-επεξεργασίαΜετά τη διαδικασία κοπής, τα εξαρτήματα ενδέχεται να υποβληθούν σε πρόσθετα βήματα μετεπεξεργασίας, όπως αφαίρεση γρεζιών, χαρακτική, ή τρίψιμο για να εξασφαλίσετε ένα καθαρό και γυαλιστερό φινίρισμα.

Οφέλη από τη χρήση μιας μηχανής κοπής μεικτού λέιζερ

Ευρεία συμβατότητα υλικώνΗ δυνατότητα κοπής μετάλλων και μη μετάλλων καθιστά αυτό το μηχάνημα ιδανικό για επιχειρήσεις που απαιτούν ευελιξία στη διαχείριση υλικών.

Κοπή υψηλής ταχύτητας: Και τα δύο λέιζερ οπτικών ινών και Λέιζερ CO2 προσφέρουν γρήγορες ταχύτητες κοπής, επιτρέποντας στις επιχειρήσεις να αυξήσουν την παραγωγικότητα και να τηρήσουν αυστηρές προθεσμίες.

Ακρίβεια και Ορθότητα: Με προηγμένο Συστήματα ελέγχου CNC, οι μικτές μηχανές κοπής με λέιζερ παρέχουν υψηλή ακρίβεια, διασφαλίζοντας ότι κάθε εξάρτημα κόβεται σύμφωνα με τις ακριβείς προδιαγραφές.

Χαμηλότερο λειτουργικό κόστοςΣυνδυάζοντας τις δυνατότητες και των δύο τεχνολογιών λέιζερ σε ένα μηχάνημα, οι επιχειρήσεις μπορούν να μειώσουν το κόστος εξοπλισμού και τα τέλη συντήρησης, αυξάνοντας παράλληλα την επιχειρησιακή αποδοτικότητα.

Προσαρμογή και ΕυελιξίαΤο μηχάνημα μπορεί να χειριστεί εύκολα προσαρμοσμένα σχέδια και υλικά, καθιστώντας το κατάλληλο για βιομηχανίες όπως προσαρμοσμένη σήμανση, κατασκευή επίπλων, και κατασκευή ακριβείας.

Σύναψη

Ο Μικτή μηχανή κοπής λέιζερ είναι ένα εξαιρετικά ευέλικτο και αποτελεσματικό εργαλείο για επιχειρήσεις που απαιτούν υψηλή ακρίβεια και την ικανότητα κοπής διαφόρων υλικών, συμπεριλαμβανομένων μέταλλο, ξύλο, πλαστικά είδη, και ακρυλικάΕίτε βρίσκεστε μέσα μεταλλική κατασκευή, κατασκευή πινακίδων, κατασκευή επίπλων, ή καλλιτεχνική γλυπτική, αυτό το μηχάνημα μπορεί να προσφέρει σημαντικά πλεονεκτήματα όσον αφορά την ταχύτητα, την ευελιξία και την οικονομική αποδοτικότητα.

Συνδυάζοντας τα δυνατά σημεία του λέιζερ οπτικών ινών και Κοπή με λέιζερ CO2 τεχνολογίες, η μηχανή κοπής μεικτού λέιζερ παρέχει την ιδανική λύση για βιομηχανίες που επιθυμούν να βελτιώσουν τις δυνατότητες κοπής τους και να βελτιστοποιήσουν τις διαδικασίες παραγωγής τους.