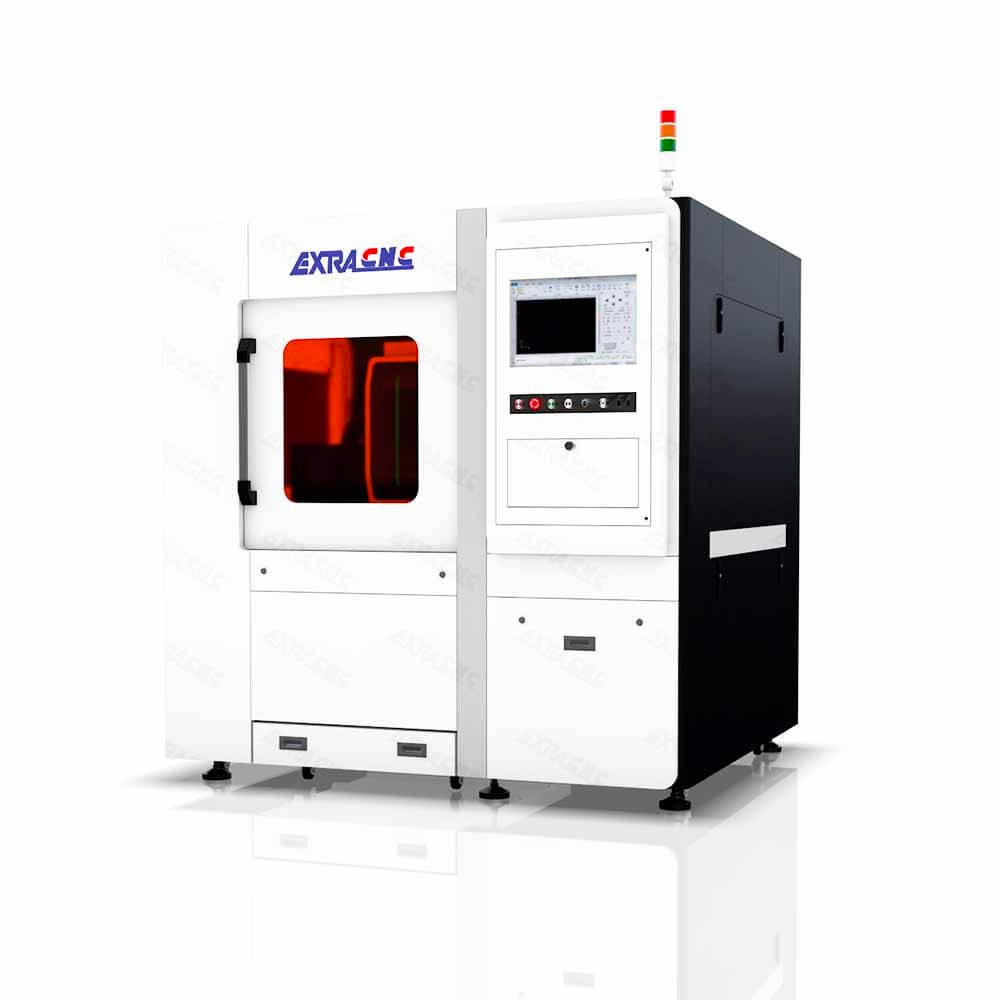

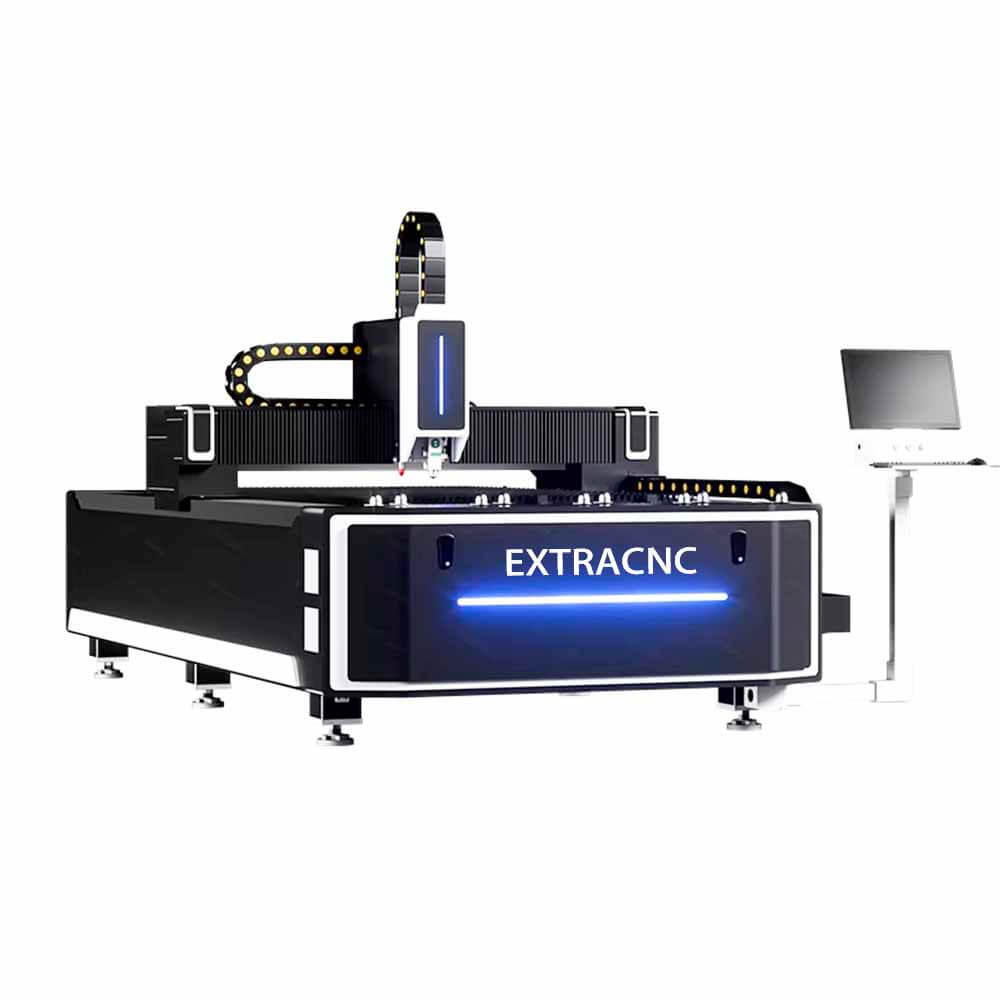

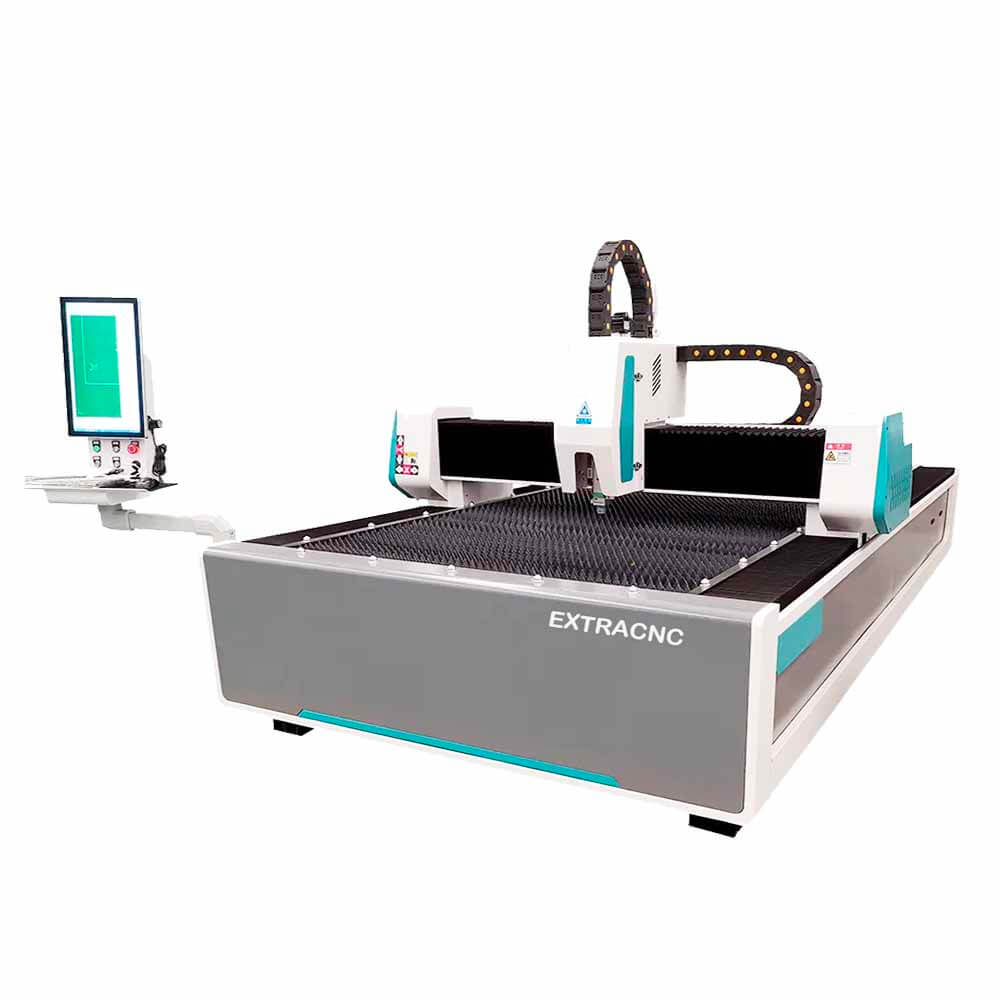

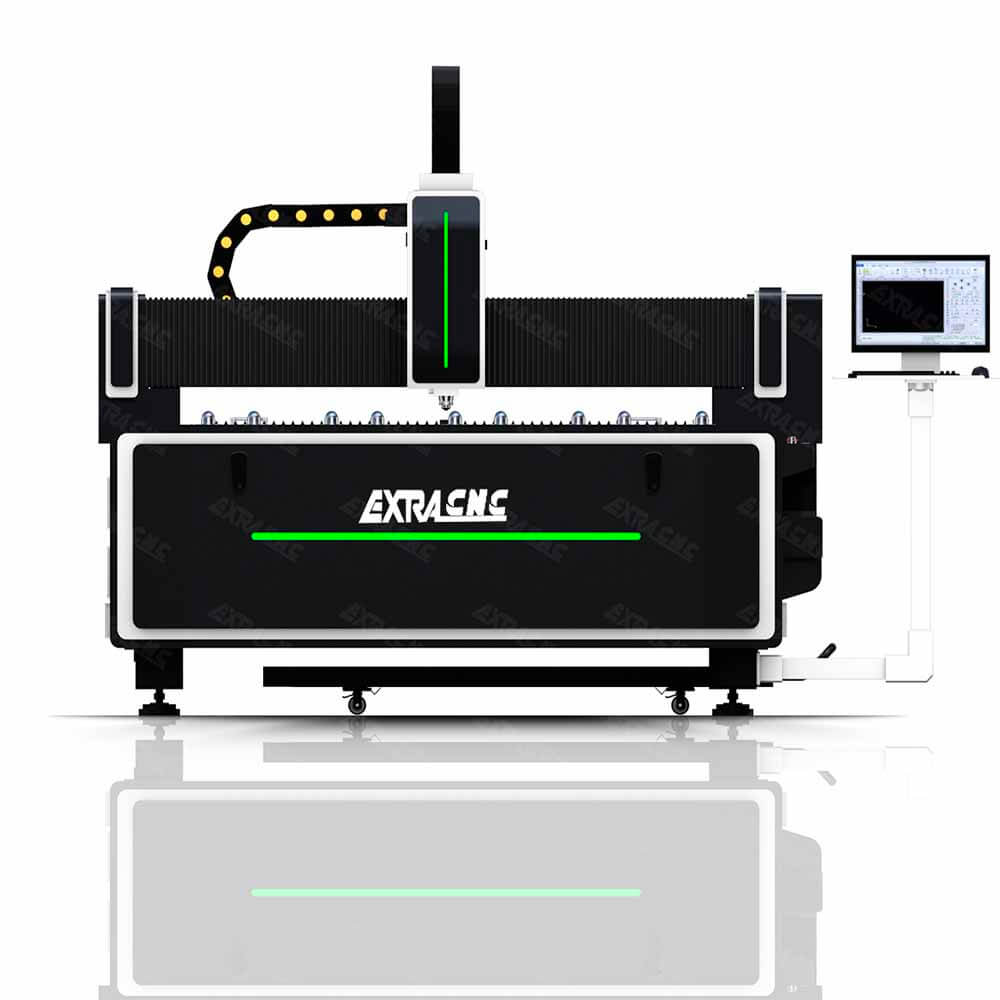

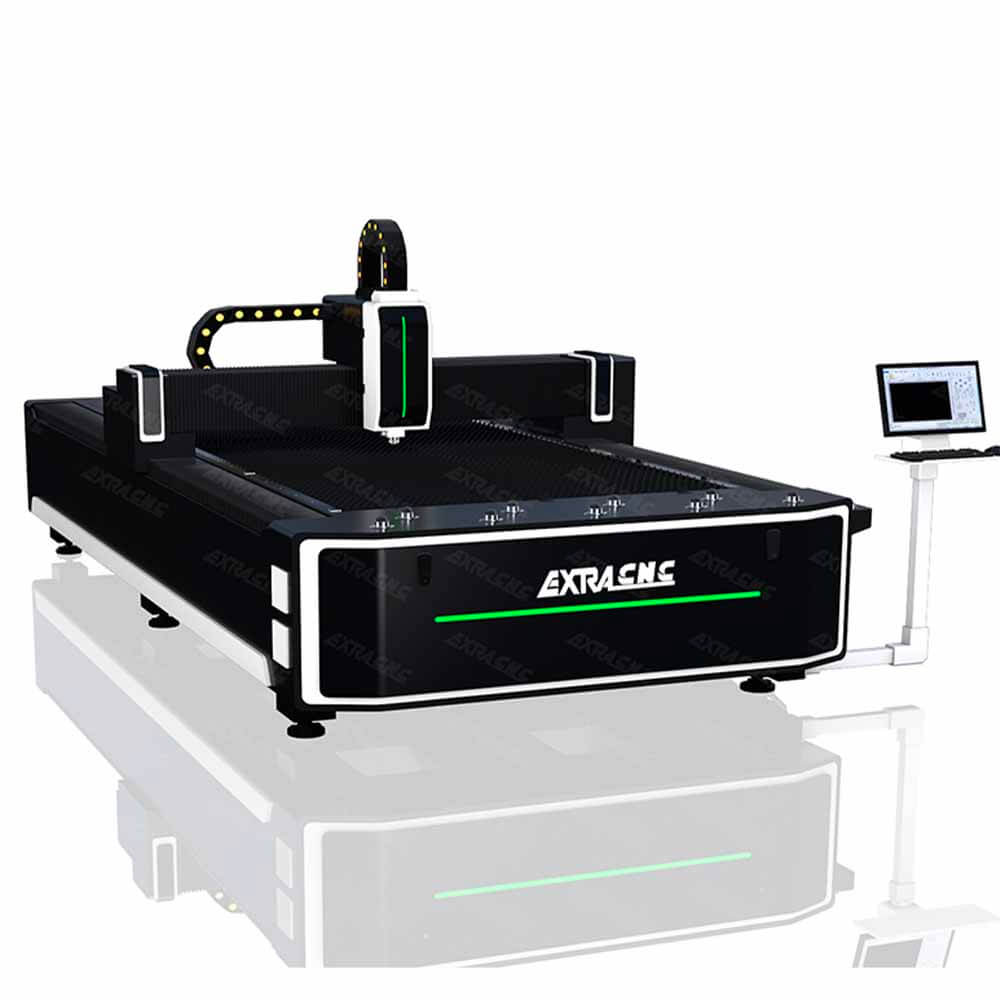

Μηχανή κοπής λέιζερ ινών

ΕΝΑ Μηχανή κοπής λέιζερ ινών είναι ένα εργαλείο κοπής υψηλής ακρίβειας που χρησιμοποιεί λέιζερ ινών για την τήξη, την καύση ή την εξάτμιση υλικού κατά μήκος μιας καθορισμένης διαδρομής κοπής. Γνωστό για την ταχύτητα, την ακρίβεια και την αποτελεσματικότητά του, είναι ιδανικό για την κοπή μιας ευρείας γκάμας μετάλλων, όπως χάλυβα, αλουμίνιο, ορείχαλκο και χαλκό, με ελάχιστη θερμική παραμόρφωση. Η τεχνολογία λέιζερ ινών επιτρέπει λεπτότερες δέσμες λέιζερ, με αποτέλεσμα καθαρές, ακριβείς κοπές με φινίρισμα υψηλής ποιότητας. Αυτά τα μηχανήματα είναι εξαιρετικά αποδοτικά, καθώς η πηγή λέιζερ ινών καταναλώνει λιγότερη ενέργεια και απαιτεί λιγότερη συντήρηση σε σύγκριση με τα παραδοσιακά λέιζερ CO2. Οι μηχανές κοπής λέιζερ ινών χρησιμοποιούνται συνήθως σε βιομηχανίες όπως η αυτοκινητοβιομηχανία, η αεροδιαστημική, η μεταλλουργία και η ηλεκτρονική, όπου η ακρίβεια και οι γρήγοροι χρόνοι παραγωγής είναι κρίσιμοι. Με προηγμένα συστήματα ελέγχου και την ικανότητα κοπής τόσο παχιών όσο και λεπτών υλικών, αποτελούν απαραίτητα εργαλεία για σύγχρονες κατασκευαστικές και βιομηχανικές εφαρμογές.

Μηχανή κοπής με λέιζερ ινών: Το μέλλον της ακριβούς κοπής μετάλλου

Ο Μηχανή κοπής λέιζερ ινών είναι ένα εργαλείο αιχμής που χρησιμοποιείται για κοπή μετάλλων υψηλής ακρίβειας. Χρησιμοποιώντας ένα λέιζερ οπτικών ινών ως πηγή ενέργειας, αυτό το μηχάνημα προσφέρει εξαιρετική ποιότητα κοπής, ταχύτητα και αποτελεσματικότητα για μια ποικιλία υλικών, συμπεριλαμβανομένων ανοξείδωτο ατσάλι, ανθρακούχος χάλυβας, αλουμίνιο, ορείχαλκος, και χαλκόςΜε τις εξελίξεις στο τεχνολογία κοπής με λέιζερ, κόφτες λέιζερ ινών έχουν γίνει η ιδανική λύση για βιομηχανίες που απαιτούν γρήγορες, ακριβείς και καθαρές κοπές.

Ποιος χρησιμοποιεί μηχανή κοπής με λέιζερ ινών;

Μηχανές κοπής με λέιζερ ινών χρησιμοποιούνται ευρέως σε βιομηχανίες που απαιτούν κοπή υψηλής ακρίβειας για την κατασκευή μετάλλων, όπως:

Εταιρείες κατασκευής μετάλλωνΓια την κοπή μεταλλικών φύλλων και εξαρτημάτων που χρησιμοποιούνται σε βιομηχανικές εφαρμογές.

Αυτοκινητοβιομηχανίες και αεροδιαστημικές βιομηχανίεςΓια την παραγωγή εξαρτημάτων όπως στηρίγματα, πάνελ και δομικά στοιχεία με περιορισμένες ανοχές.

Επιχειρήσεις κατασκευής πινακίδωνΓια την κοπή περίπλοκων σχεδίων και λογότυπων από μέταλλο για προσαρμοσμένες πινακίδες.

Κατασκευαστές εργαλείων και μήτρωνΓια τη δημιουργία εργαλείων και καλουπιών ακριβείας.

Κατασκευές και μεταποίησηΓια την κοπή μεγάλων φύλλων χάλυβα ή αλουμινίου που χρησιμοποιούνται σε κατασκευαστικά έργα και βιομηχανικό εξοπλισμό.

Καταστήματα κατασκευής κατά παραγγελίαΓια την παραγωγή μικρών παρτίδων ή μεταλλικών εξαρτημάτων κατά παραγγελία με οικονομικά αποδοτικό τρόπο.

Τι είναι μια μηχανή κοπής με λέιζερ ινών;

ΕΝΑ μηχανή κοπής λέιζερ ινών είναι ένα εξαιρετικά προηγμένο σύστημα που χρησιμοποιεί λέιζερ οπτικών ινών για κοπή μετάλλου και άλλων υλικών με υψηλή ακρίβεια και ταχύτητα. Σε αντίθεση με τις παραδοσιακές μηχανές κοπής με λέιζερ, οι οποίες χρησιμοποιούν λέιζερ CO2, κόφτες λέιζερ ινών χρησιμοποιήστε ένα λέιζερ οπτικών ινών στερεάς κατάστασης, το οποίο προσφέρει πολλά πλεονεκτήματα όσον αφορά την απόδοση, την ποιότητα κοπής και το λειτουργικό κόστος.

Το λέιζερ οπτικών ινών εστιάζει σε μια συγκεντρωμένη δέσμη που μπορεί να λιώσει, να κάψει ή να εξατμίσει υλικό, καθιστώντας το ιδανικό για την κοπή μεταλλικών φύλλων, σωλήνων και άλλων εξαρτημάτων. Τεχνολογία κοπής με λέιζερ ινών επιτρέπει εξαιρετικά λεπτές κοπές, επεξεργασία υψηλής ταχύτητας και ελάχιστη παραμόρφωση υλικού.

Πού χρησιμοποιούνται οι μηχανές κοπής με λέιζερ ινών;

Οι μηχανές κοπής με λέιζερ ινών χρησιμοποιούνται σε διάφορες βιομηχανίες λόγω της ευελιξίας και της ικανότητάς τους να κόβουν ένα ευρύ φάσμα υλικών. Αυτές περιλαμβάνουν:

Κοπή μετάλλου: Χρησιμοποιείται κυρίως για κοπή ανοξείδωτο ατσάλι, ανθρακούχος χάλυβας, αλουμίνιο, και ορείχαλκος σε βιομηχανίες όπως αυτοκινητοβιομηχανία, αεροδιαστημική, και κατασκευή εργαλείων.

Κατασκευή λαμαρίνας: Χρησιμοποιείται για κοπή μεταλλικά φύλλα σε εξαρτήματα για μηχανήματα, κατασκευές και συσκευές.

Κατασκευή πινακίδωνΔημιουργία προσαρμοσμένων πινακίδων και διακοσμητικών από μέταλλο ή ανοξείδωτο ατσάλι.

Ακριβής κατασκευήΙδανικό για κοπή εξαρτημάτων με περίπλοκα σχήματα, υψηλή ακρίβεια και επαναληψιμότητα.

Πρωτότυπα και κατασκευή κατά παραγγελίαΧρησιμοποιείται σε ταχεία πρωτοτυποποίηση για μεταλλικά μέρη κατά παραγγελία, καλούπια, και άλλα προϊόντα.

Πότε έγιναν δημοφιλείς οι μηχανές κοπής με λέιζερ ινών;

Οι μηχανές κοπής με λέιζερ ινών έγιναν ολοένα και πιο δημοφιλείς τη δεκαετία του 2000, καθώς η τεχνολογία λέιζερ ινών ωρίμασε και έγινε πιο προσιτή για βιομηχανική χρήση. κόπτης λέιζερ ινών έφερε επανάσταση στην κοπή μετάλλων προσφέροντας ταχύτερες ταχύτητες κοπής, καλύτερη ακρίβεια και χαμηλότερο λειτουργικό κόστος σε σύγκριση με τις παραδοσιακές Μηχανές κοπής με λέιζερ CO2Η στροφή στην τεχνολογία κοπής με λέιζερ ινών επέτρεψε σε βιομηχανίες όπως αυτοκινητοβιομηχανία, αεροδιαστημική, και κατασκευή ηλεκτρονικών ειδών για να καλύψουν την αυξανόμενη ζήτηση για υψηλής ποιότητας, σύνθετα μεταλλικά εξαρτήματα.

Γιατί είναι σημαντικές οι μηχανές κοπής με λέιζερ ινών;

Υψηλή ακρίβεια και ακρίβειαΟι μηχανές κοπής με λέιζερ ινών προσφέρουν απίστευτα ακριβείς και καθαρές κοπές, με υψηλή επαναληψιμότητα. Αυτό είναι κρίσιμο για τις βιομηχανίες που απαιτούν ακριβή, σύνθετα εξαρτήματα με περιορισμένες ανοχές.

Ταχύτητα και Αποδοτικότητα: Το λέιζερ οπτικών ινών Η διαδικασία κοπής είναι ταχύτερη από τις παραδοσιακές μεθόδους, επιτρέποντας υψηλότερη απόδοση και μειωμένους χρόνους παραγωγής. Αυτή η αυξημένη ταχύτητα είναι επωφελής για την κατασκευή μεγάλου όγκου και την κοπή μετάλλου κατά παραγγελία.

Ελάχιστη παραμόρφωση υλικούΗ συγκεντρωμένη ενέργεια της δέσμης λέιζερ οπτικών ινών ελαχιστοποιεί τις ζώνες που επηρεάζονται από τη θερμότητα (HAZ), μειώνοντας την παραμόρφωση του υλικού κατά την κοπή. Αυτό έχει ως αποτέλεσμα καλύτερη ποιότητα εξαρτήματος και λιγότερη ανάγκη για μετεπεξεργασία.

Οικονομικά Αποδοτική ΛειτουργίαΟι μηχανές κοπής με λέιζερ ινών απαιτούν λιγότερη συντήρηση και ενέργεια από Κόφτες λέιζερ CO2, καθιστώντας τα μια πιο οικονομικά αποδοτική λύση για εταιρείες που επιδιώκουν να βελτιστοποιήσουν τις λειτουργίες τους.

Ευέλικτες δυνατότητες κοπήςΑυτά τα μηχανήματα μπορούν να κόψουν ένα ευρύ φάσμα υλικών, συμπεριλαμβανομένων παχύ ανοξείδωτο ατσάλι, αλουμίνιο, χαλκός, και ορείχαλκος, καθώς και μη μεταλλικά υλικά σαν πλαστική ύλη και σύνθετα υλικά.

Χαμηλές απαιτήσεις συντήρησης: Ο σχεδιασμός στερεάς κατάστασης του λέιζερ οπτικών ινών απαιτεί λιγότερη συντήρηση σε σύγκριση με τα παραδοσιακά συστήματα κοπής με λέιζερ, μειώνοντας τον χρόνο διακοπής λειτουργίας και το λειτουργικό κόστος.

Πώς λειτουργεί μια μηχανή κοπής με λέιζερ οπτικών ινών;

Φάση Σχεδιασμού: Δημιουργείται ένα λεπτομερές σχέδιο χρησιμοποιώντας CAD (Σχεδίαση με τη βοήθεια υπολογιστή) λογισμικό. Ο σχεδιασμός καθορίζει τις διαστάσεις, τα σχήματα και τις διαδρομές κοπής που απαιτούνται για το εξάρτημα.

Προγραμματισμός CAM: Το σχέδιο CAD στη συνέχεια μετατρέπεται σε ένα CAM (Υποβοηθούμενη από Υπολογιστή Κατασκευή) αρχείο. Αυτό το αρχείο περιέχει οδηγίες κοπής με τη μορφή Κώδικας G, το οποίο καθοδηγεί τη μηχανή κοπής με λέιζερ ινών.

Ρύθμιση ΥλικούΤο μεταλλικό φύλλο ή το εξάρτημα που πρόκειται να κοπεί τοποθετείται στην πλατφόρμα κοπής. Συχνά ασφαλίζεται χρησιμοποιώντας τραπέζια κενού αέρος, σφιγκτήρες, ή ράγες για να εξασφαλιστεί η σταθερότητα κατά τη διαδικασία κοπής.

Διαδικασία κοπής με λέιζερΤο λέιζερ οπτικών ινών εστιάζει στην επιφάνεια του υλικού. Η δέσμη λέιζερ λιώνει, εξατμίζεται ή καίγεται διαμέσου του υλικού καθώς η κεφαλή κοπής κινείται κατά μήκος των προγραμματισμένων διαδρομών. Χρησιμοποιείται ένα αέριο (όπως άζωτο ή οξυγόνο) για να βοηθήσει στη διαδικασία κοπής, απομακρύνοντας το τηγμένο υλικό.

Μετα-επεξεργασίαΜετά τη διαδικασία κοπής, τα εξαρτήματα ενδέχεται να υποστούν εργασίες φινιρίσματος όπως αφαίρεση γρεζιών, τρίψιμο, ή καθάρισμα για να αφαιρέσετε τυχόν υπολείμματα υλικού ή αιχμηρές άκρες.

Πλεονεκτήματα των μηχανών κοπής με λέιζερ ινών

Εξαιρετική ταχύτητα κοπήςΤα λέιζερ οπτικών ινών προσφέρουν ταχύτερες ταχύτητες κοπής σε σύγκριση με τα παραδοσιακά λέιζερ CO2, αυξάνοντας την αποδοτικότητα της παραγωγής και την απόδοση.

Ακρίβεια και ΛεπτομέρειαΗ λεπτή, συμπυκνωμένη δέσμη λέιζερ επιτρέπει ακριβείς, καθαρές κοπές με ελάχιστες ζώνες που επηρεάζονται από τη θερμότητα και ελάχιστα έως καθόλου γρέζια.

Μειωμένο Λειτουργικό ΚόστοςΤα λέιζερ οπτικών ινών είναι γνωστά για τα μεγάλη διάρκεια ζωής, χαμηλές απαιτήσεις συντήρησης, και μειωμένη κατανάλωση ενέργειας, κάτι που βοηθά τις εταιρείες να εξοικονομούν χρήματα μακροπρόθεσμα.

Ευστροφία: Ικανότητα κοπής διαφόρων υλικών, από μέταλλο να πλαστικά είδη και σύνθετα υλικά, οι μηχανές κοπής με λέιζερ ινών είναι ιδανικές για εφαρμογές που κυμαίνονται από μεταλλική κατασκευή κατά παραγγελία να κατασκευή πινακίδων και αεροδιαστημική κατασκευή.

Ελάχιστη σπατάλη υλικώνΗ ακρίβεια του λέιζερ οπτικών ινών ελαχιστοποιεί την ανάγκη για επιπλέον υλικό και μειώνει τη σπατάλη, καθιστώντας το μια οικολογική επιλογή.

Χαμηλότερο κόστος λειτουργίαςΤα λέιζερ οπτικών ινών είναι γνωστά για τα χαμηλό λειτουργικό κόστος, καθιστώντας τα μια οικονομικά αποδοτική επιλογή για παραγωγή μεγάλου όγκου.

Σύναψη

Ο μηχανή κοπής λέιζερ ινών είναι μια προηγμένη και οικονομικά αποδοτική λύση για βιομηχανίες που απαιτούν ακριβή και γρήγορη κοπή μετάλλου. Είτε βρίσκεστε σε μεταλλική κατασκευή, αυτοκινητοβιομηχανία, αεροδιαστημική, ή παραγωγή μεταλλικών εξαρτημάτων κατά παραγγελία, μια μηχανή κοπής με λέιζερ ινών προσφέρει απαράμιλλα πλεονεκτήματα σε ταχύτητα, ακρίβεια και αποτελεσματικότητα. Με την ικανότητα κοπής μιας μεγάλης ποικιλίας υλικών με ελάχιστη παραμόρφωση και χαμηλότερο λειτουργικό κόστος, η επένδυση σε ένα κόπτης λέιζερ ινών είναι μια στρατηγική απόφαση για επιχειρήσεις που επιθυμούν να βελτιώσουν την παραγωγικότητά τους και την ποιότητα των εξαρτημάτων τους.

Για τους κατασκευαστές που επιθυμούν να βελτιώσουν τις δυνατότητες κοπής τους, η τεχνολογία οπτικών ινών λέιζερ αντιπροσωπεύει το μέλλον της ακριβούς κοπής.