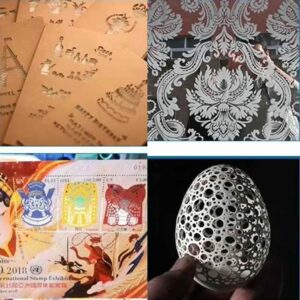

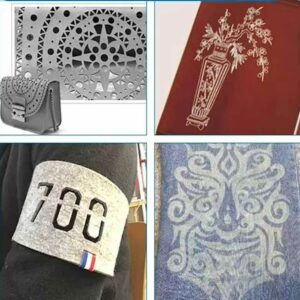

Das Laserschneid- und Graviermaschine Die Maschine wird branchenübergreifend eingesetzt, um Acrylbuchstaben und Displayschilder herzustellen, individuelle Muster auf Lederwaren zu gravieren und filigrane Hohlmuster auf Kleidungsstücken und Stoffen zu schneiden. Sie eignet sich außerdem ideal für die Herstellung von Gummidruckplatten, dekoratives Keramikhandwerk und die Verarbeitung von Bambus- und Holzmaterialien für künstlerische Zwecke und die Innenarchitektur. Ob für personalisiertes Branding, Präzisionsschnitte oder detaillierte Gravuren – diese Maschine liefert zuverlässige Ergebnisse auf einer Vielzahl nichtmetallischer Materialien.