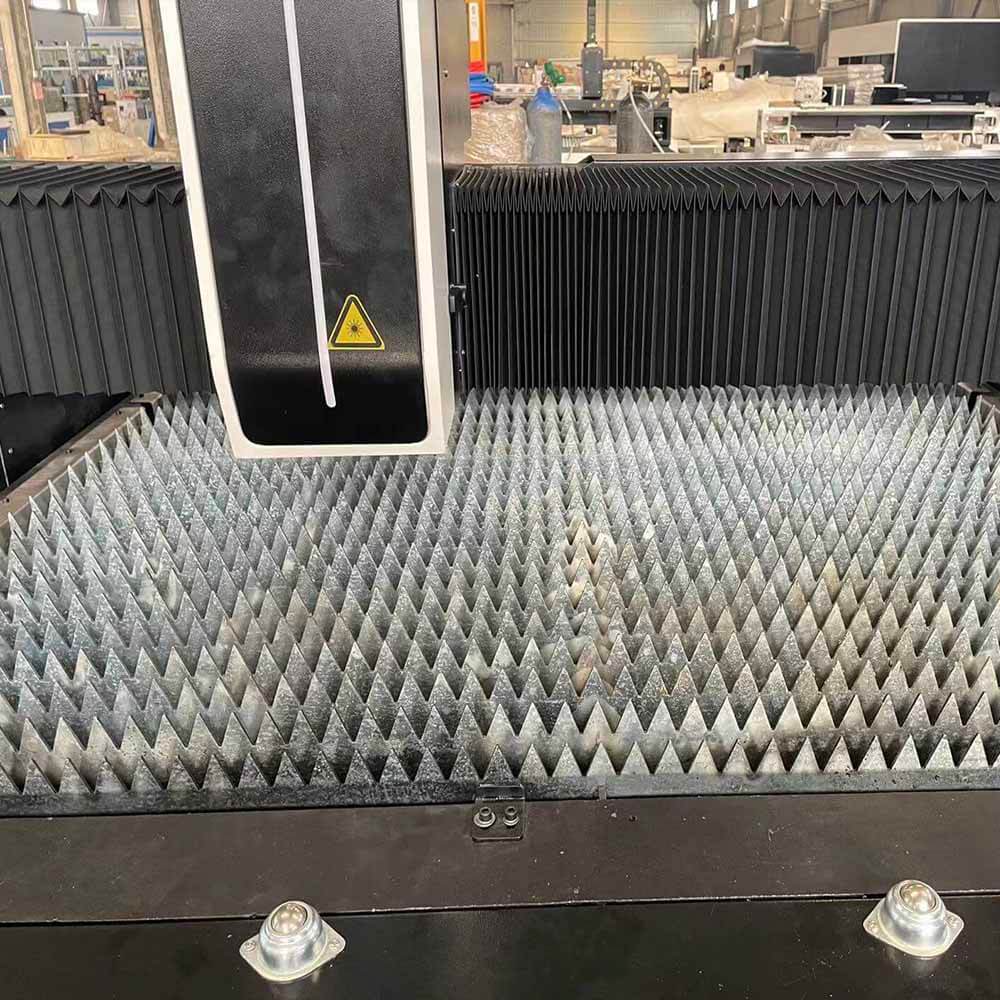

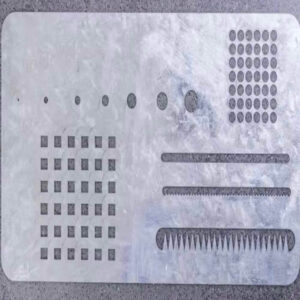

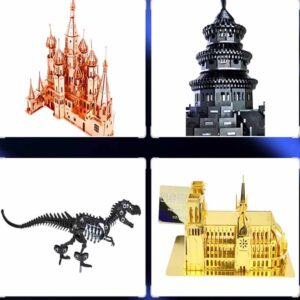

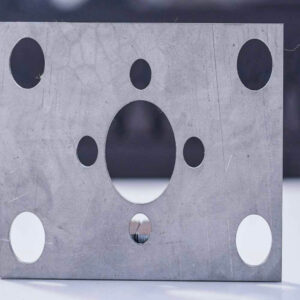

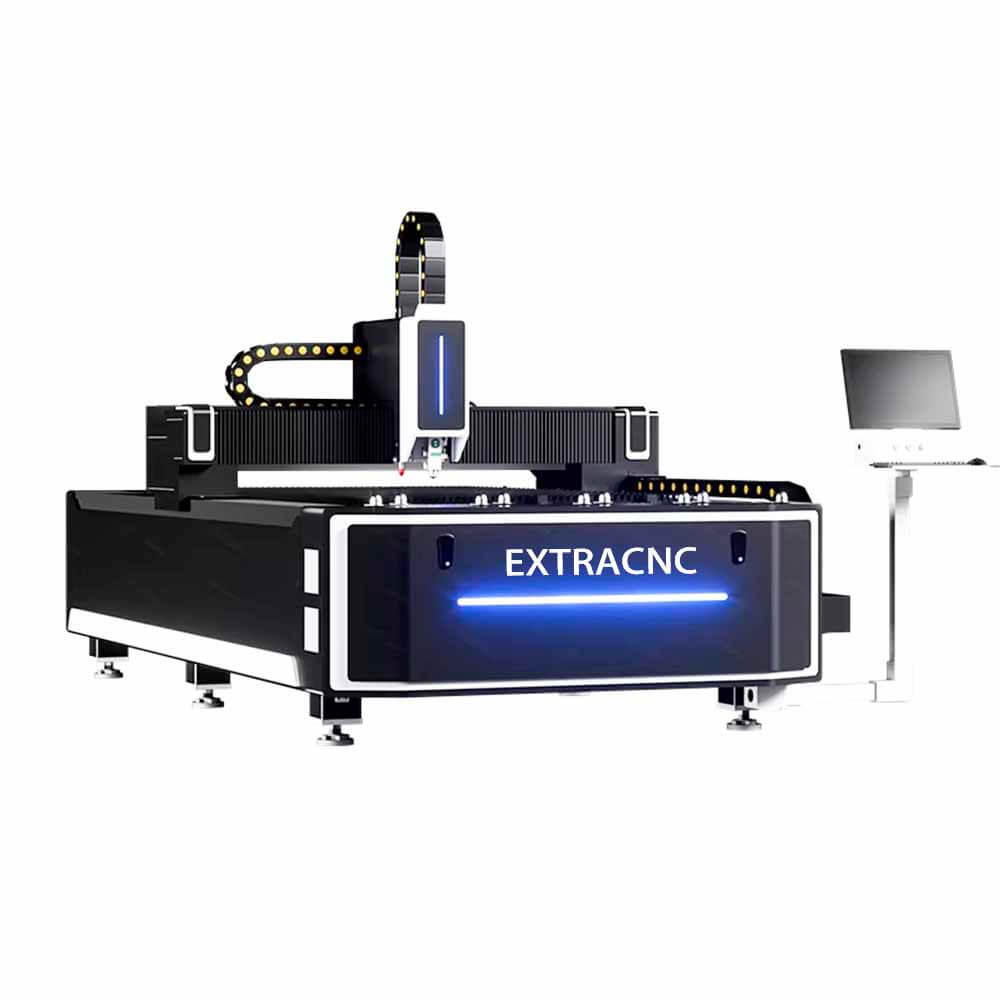

Faserlaserschneider werden in der Metallverarbeitung, der Automobil-, Luft- und Raumfahrt- sowie der Elektronikindustrie zum präzisen Schneiden von Edelstahl, Kohlenstoffstahl, Aluminium, Kupfer, Messing und Titan eingesetzt. Sie verarbeiten sowohl Bleche als auch Rohre effizient und eignen sich daher ideal für Industrieteile, kundenspezifische Gehäuse und dekorative Metallarbeiten.