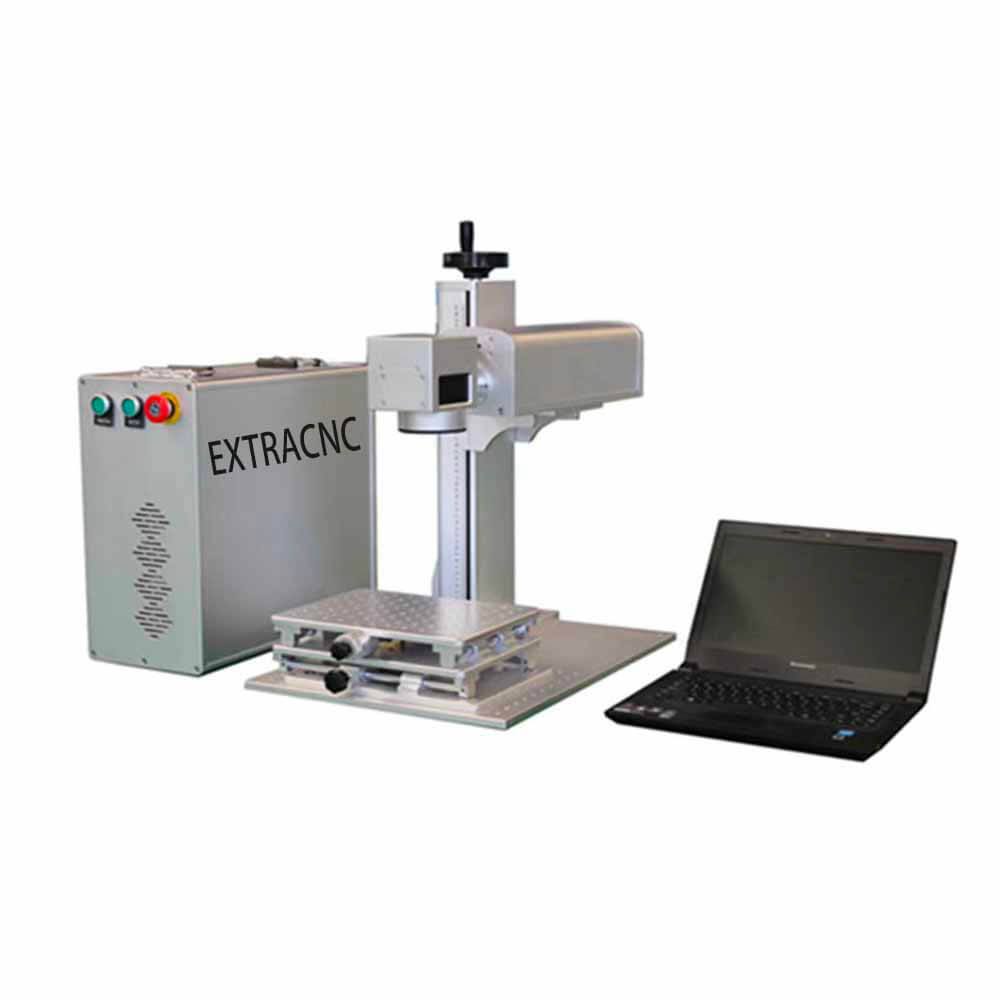

Fiber Laser Marking Machine

AFiber Laser Marking Machinekay usa ka high-precision, high-speed device nga gigamit sa pagmarka, pagkulit, o pag-etch sa mga permanenteng pattern, logo, serial number, barcode, ug text ngadto sa metal ug pipila ka plastik nga ibabaw. Gigamit ang usa ka gigikanan sa fiber laser, naghatud kini usa ka konsentrado nga laser beam nga adunay maayo kaayo nga kalidad sa beam ug mubu nga pagkonsumo sa kuryente, nga nagresulta sa maayo, detalyado, ug lig-on nga mga marka. Kini nga mga makina kaylap nga gigamit sa mga industriya sama sa electronics, automotive, aerospace, medikal nga mga himan, ug mga himan sa paghimo, diin ang katin-awan, katulin, ug dugay nga mga marka hinungdanon. Ang mga makina sa pagmarka sa fiber laser nanginahanglan gamay nga pagmentinar, naglihok nga wala’y mga magamit, ug nagtanyag paspas nga mga katulin sa pagproseso nga adunay talagsaon nga pagkamakanunayon, nga naghimo kanila nga usa ka episyente ug mahigalaon sa kalikopan nga solusyon alang sa modernong mga panginahanglanon sa pagmarka.

Fiber Laser Marking Machine: Precision, Speed, ug Reliability alang sa Industrial Marking

A Fiber Laser Marking Machine kay usa ka high-precision device nga naggamit ug fiber laser beam para maghimo ug permanenteng marka sa lain-laing mga materyales, lakip na mga metal, mga plastik, ug mga seramiko. Nailhan tungod sa kalig-on, katulin, ug gamay nga pagmentinar, ang fiber laser marking machine kaylap nga gigamit sa mga industriya sama sa sakyanan, elektroniko, alahas, aerospace, ug medikal nga ekipo paghimo. Gisusi sa kini nga artikulo ang mga aplikasyon, benepisyo, ug operasyon sa mga sistema sa pagmarka sa fiber laser ug kung ngano nga hinungdanon kini alang sa modernong mga palibot sa produksiyon.

Kinsa ang Naggamit ug Fiber Laser Marking Machine?

Ang fiber laser marking machine gigamit sa usa ka halapad nga industriya nga nanginahanglan tukma, lig-on, ug masubay nga mga marka:

Industriya sa awto: Alang sa pagmarka sa mga VIN code, serial number, ug mga label sa kaluwasan sa mga piyesa ug sangkap sa makina.

Mga tiggama sa elektroniko: Alang sa pagmarka sa mga PCB board, barcode, ug QR code sa plastik o metal nga mga ibabaw.

Mga alahas ug luho nga mga butang: Para sa pagkulit og mga logo, serial number, o custom nga mga mensahe sa bulawan, pilak, ug stainless steel.

Mga kompanya sa medikal nga aparato: Para sa pagsunod sa FDA nga pagmarka sa mga himan ug instrumento sa pag-opera.

Mga himan ug mamatay nga tigbuhat: Para sa pag-ila sa bahin ug pagkulit sa logo sa gahi nga metal nga mga ibabaw.

Mga tiggama sa hardware ug bearing: Alang sa pagmarka sa mga code sa produkto ug mga numero sa batch nga adunay taas nga katin-aw.

Unsa ang Fiber Laser Marking Machine?

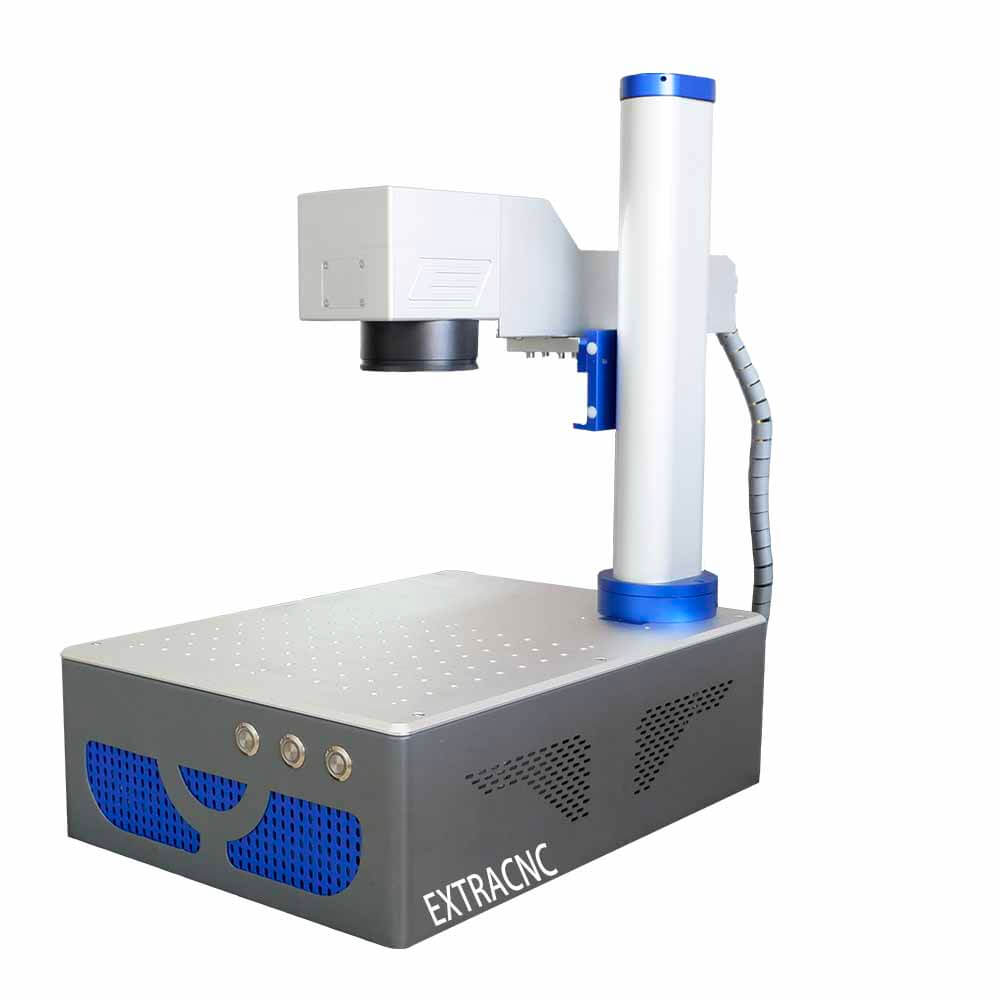

Ang usa ka makina sa pagmarka sa fiber laser usa ka klase sa sistema sa pagmarka sa laser nga naggamit usa ka gigikanan sa fiber laser aron makahimo usa ka taas nga intensity nga laser beam, nga nakig-uban sa nawong sa usa ka materyal aron makahimo mga permanente nga marka pinaagi sa pag-annealing, pag-ukit, o pagkulit.

Ang mga fiber laser naggamit ug fiber-optic nga kable nga doped nga adunay talagsaon nga mga elemento sa yuta sama sa ytterbium aron makamugna og usa ka gamhanan nga laser beam nga adunay wavelength nga 1064nm—maayo alang sa pagmarka sa mga metal ug high-density nga plastik. Ang sistema sa kasagaran adunay himan nga galvanometer scanner, laser software, ug usa ka control panel, nga nagsiguro nga paspas, tukma, ug balik-balik nga operasyon.

Asa ang Fiber Laser Marking Machines Gigamit?

Ang mga makina sa pagmarka sa fiber laser gigamit sa daghang mga aplikasyon, lakip ang:

Pagmarka sa bahin sa metal: Pagkulit sa mga serial number, modelo nga numero, logo, ug traceability code sa stainless steel, aluminum, brass, copper, ug titanium.

Pagmarka sa sangkap sa plastik: Pagmarka sa ABS, PVC, polycarbonate, ug uban pang mga plastik nga engineering nga wala’y deformation.

Paggama sa himan: Pag-ukit sa mga numero sa bahin ug pagmarka sa mga himan sa pagputol, wrenches, ug mga socket.

Pag-ukit sa relo ug alahas: Paghimo ug delikado nga mga marka ug naandang mga disenyo nga adunay taas nga katukma.

Produksyon sa elektroniko: Pagmarka sa mga PCB, chip casing, ug mga balay sa aparato aron masubay.

Mga instrumento sa medikal: Steril ug lig-on nga pag-ila sa bahin sa mga gamit sa pag-opera.

Kanus-a Nahimong Popular ang Fiber Laser Marking Machines?

Ang teknolohiya sa fiber laser nagsugod nga nakakuha og traksyon sa sayong bahin sa 2000s tungod sa taas nga kalidad sa beam, kahusayan sa enerhiya, ug taas nga kinabuhi sa operasyon. Kung itandi sa mga daan nga teknolohiya sama sa CO₂ lasers ug inkjet printers, ang fiber laser marking machines nagtanyag og mas maayo nga tulin, katukma, ug ubos nga gasto sa operasyon. Karon, gikonsiderar sila nga sumbanan sa industriya alang sa taas nga gidaghanon, taas nga katukma nga mga kinahanglanon sa pagmarka.

Ngano nga Pagpili usa ka Fiber Laser Marking Machine?

Taas nga Marking Speed

Salamat sa mga sistema sa pag-scan sa galvanometer, ang mga makina sa pagmarka sa fiber laser mahimo’g molihok sa labi ka taas nga katulin, nga himuon kini nga sulundon alang sa daghang mga aplikasyon sa industriya.

Talagsaong Kalidad sa Pagmarka

Ang fiber lasers naghimo og mga presko, taas nga resolusyon nga mga marka nga permanente, mabasa, ug dili masul-ob, kemikal, ug kainit—perpekto para sa pagsubay ug pag-ila sa produkto.

Taas nga Kinabuhi ug Ubos nga Pagmentinar

Uban sa gipaabot nga kinabuhi sa tinubdan sa laser nga kapin sa 100,000 ka oras, kini nga mga makina nanginahanglan gamay nga pagmentinar, pagkunhod sa downtime ug gasto sa serbisyo.

Mahigalaon sa kinaiyahan

Dili sama sa pagmarka nga gibase sa tinta, ang pagmarka sa fiber laser usa ka limpyo nga proseso-walay mga magamit, walay kemikal, ug walay basura, nga naghimo niini nga responsable sa kinaiyahan.

Nahiangay sa usa ka halapad nga mga Materyal

Ang mga fiber laser epektibo sa mga metal, plastik, adunay sapaw nga mga materyales, ug mga komposit, nga naghatag maayo kaayo nga versatility sa mga industriya.

Dili Kinahanglan ang Pre/Post-Processing

Ang mga marka gihimo direkta sa materyal nga nawong nga wala magkinahanglan dugang nga mga lakang, nga nagdugang sa kinatibuk-ang produktibo.

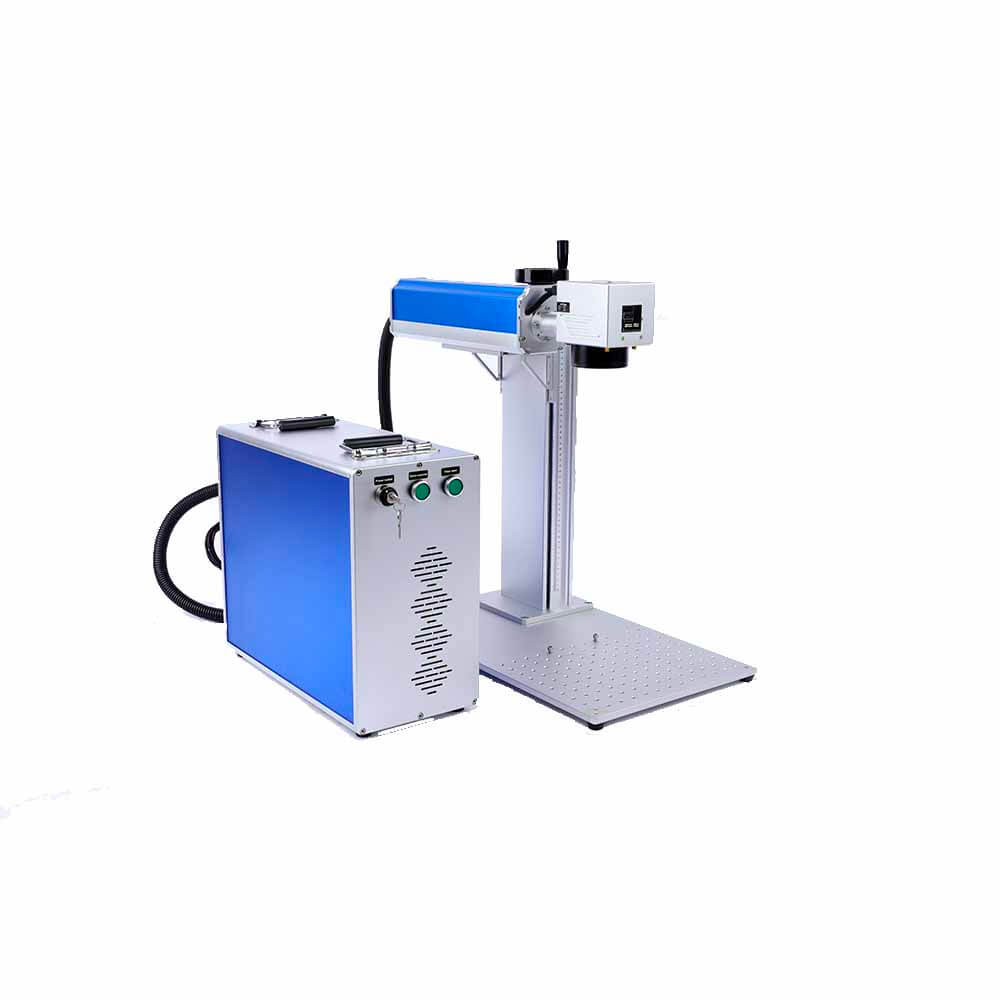

Giunsa Nagtrabaho ang Fiber Laser Marking Machine?

Disenyo ug Setup

Ang sumbanan sa pagmarka gihimo gamit ang software sa pagmarka sa laser, sama sa EZCAD o LightBurn. Ang operator nag-upload og mga logo, serial number, o mga barcode alang sa pagkulit.

Pagbutang sa Materyal

Ang workpiece gipahimutang sa higdaanan sa makina, kasagaran adunay rotary attachment o fixture alang sa cylindrical nga mga butang.

Proseso sa Pagmarka sa Laser

Ang fiber laser beam gipunting sa ibabaw, nga nagmugna sa tukma, dili kontak nga mga marka pinaagi sa lokal nga pagpainit o oksihenasyon.

Pagsusi sa Kalidad ug Pagkompleto

Human sa pagmarka, ang mga bahin gisusi alang sa pagkamakanunayon, ug walay dugang nga paglimpyo o pagproseso nga gikinahanglan.

Mga Kaayohan sa Paggamit sa Fiber Laser Marking Machine

High-speed nga pagmarka sa metal ug plastik

Permanente, taas nga kalainan nga pagkulit

Walay mga gamit o tinta

Non-contact, walay kadaot sa materyal

Operasyon nga walay maintenance

Maayo alang sa QR code, barcode, ug pagkulit sa logo

Maayo kaayo nga kalig-on ug pagkamakanunayon sa beam

Ang user-friendly nga interface nga adunay tukma nga mga kontrol

Panapos

Ang Fiber Laser Marking Machine usa ka hinungdanon nga himan alang sa modernong mga palibot sa paghimo nga nanginahanglan katulin, katukma, ug kalig-on. Kung nagmarka ka mga medikal nga instrumento, mga piyesa sa awto, o naandan nga alahas, ang fiber laser marker naghatag dili hitupngan nga pasundayag nga adunay gamay nga gasto sa operasyon. Ang pagka-epektibo niini, pagkamahigalaon sa ekolohiya, ug pagkaangay sa usa ka halapad nga mga materyales naghimo niini nga usa ka maalamon nga pagpamuhunan alang sa mga kompanya nga nagtinguha nga ipataas ang ilang branding sa produkto, pagkasunud, ug pagkontrol sa kalidad.