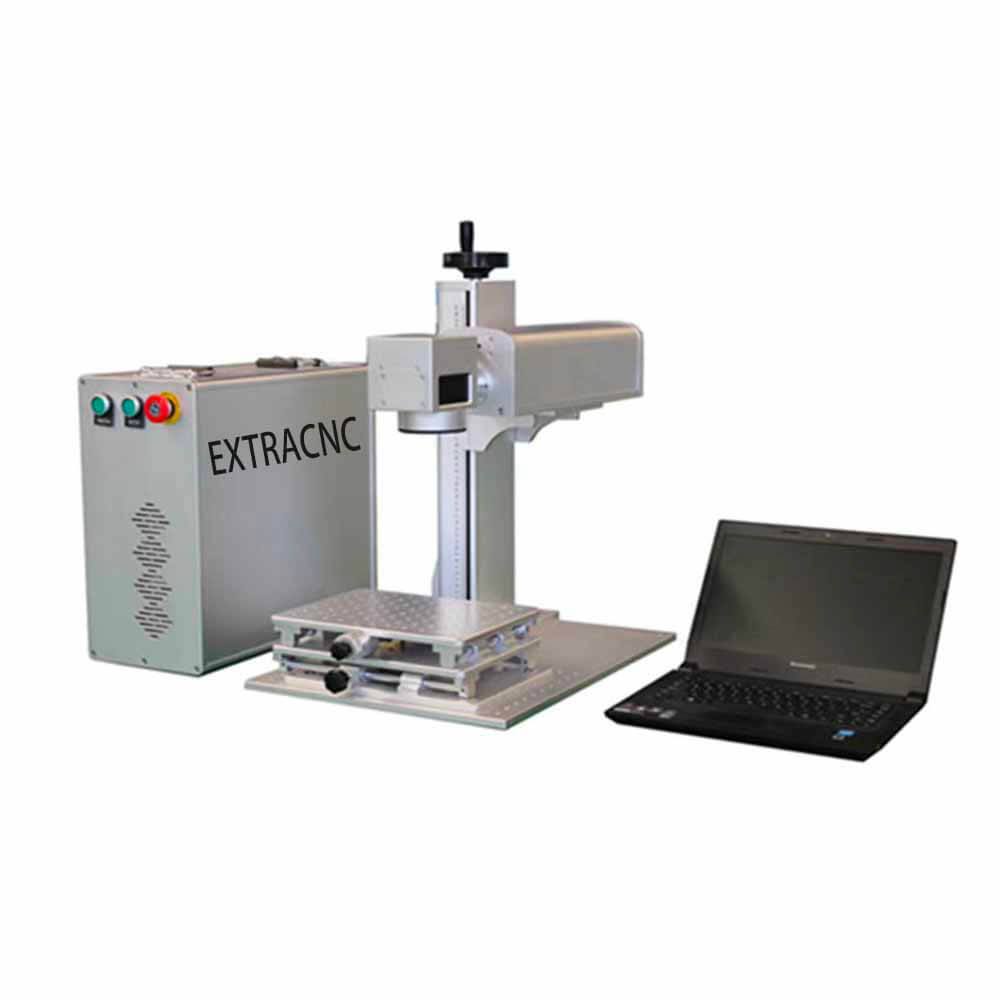

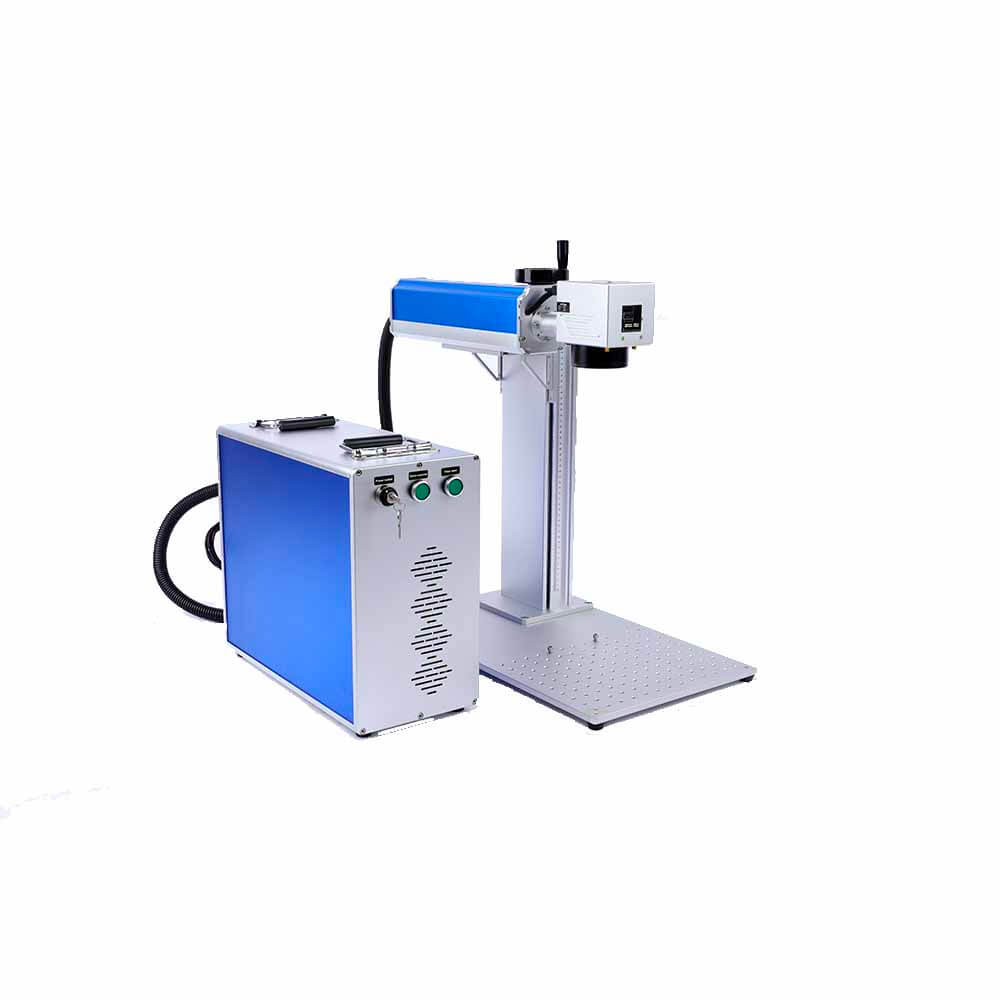

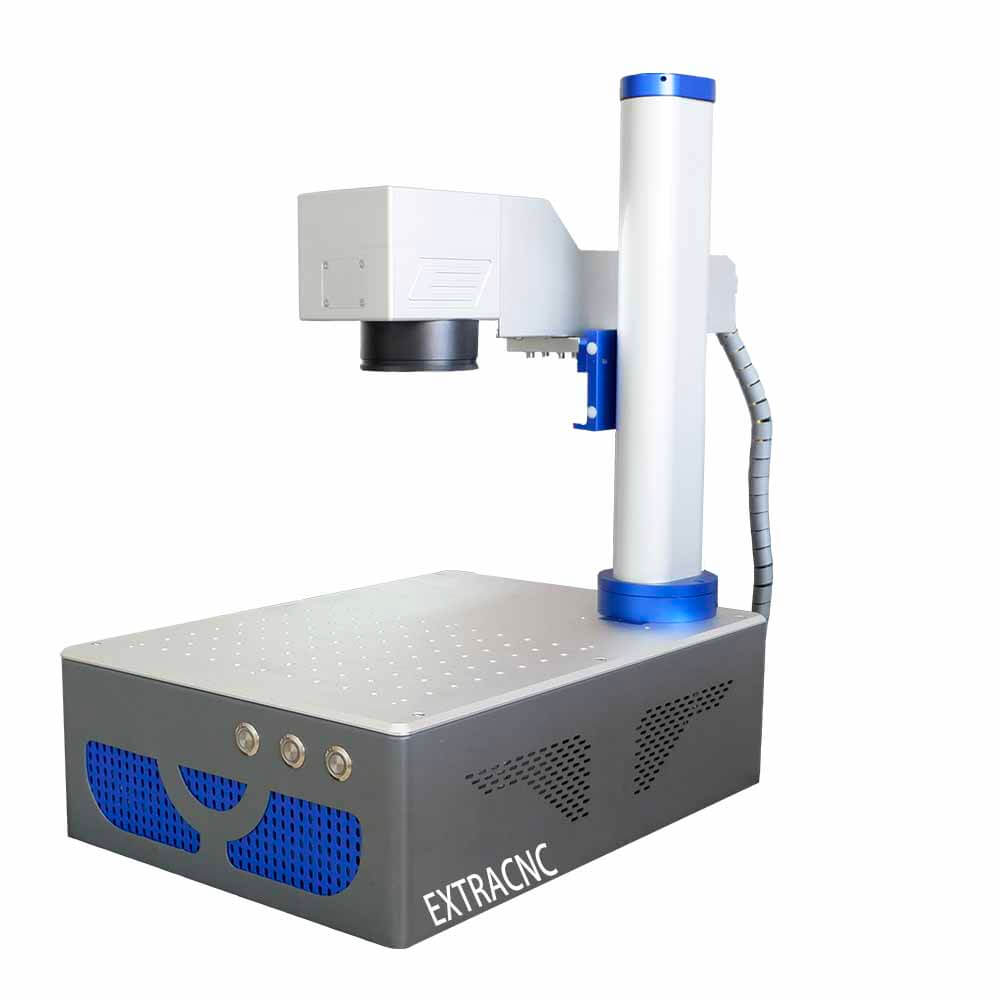

EXTRA CNC Laser nga nagtimaan sa MACHINE FACTORY SUPPLIER

A Laser Marking Machine kay usa ka high-precision industrial device nga naggamit ug laser beam sa pag-etch, pagmarka, o pagkulit sa nagkalain-laing materyales sama sa metal, plastic, ceramics, ug glass. Gigamit ang advanced nga teknolohiya sa laser, naghatag kini og taas nga katukma, katulin, ug kalidad nga mga marka, nga naghimo niini nga sulundon alang sa mga industriya sama sa electronics, automotive, medikal nga aparato, aerospace, ug mga gamit sa konsumidor. Ang proseso sa pagmarka sa laser naghatod ug permanente, tin-aw, ug lig-on nga mga marka nga dili masul-ob ug mawala. Dili sama sa tradisyonal nga mekanikal nga mga pamaagi sa pagmarka, ang makina sa pagmarka sa laser wala’y kontak, dili makadaot, ug wala magkinahanglan mga magamit, nga naghimo niini nga mahigalaon sa kalikopan. Barcode man kini, QR code, serial number, logo, o custom text ug graphics, ang laser marking machine episyente nga nagdumala sa tukma nga pagmarka sa komplikado ug gagmay nga mga workpiece, pagpalambo sa produksyon nga kahusayan ug pagdugang sa bili sa mga produkto.

Laser Marking Machine: Precision, Speed, ug Versatility sa Modernong Paggama

A makina sa pagmarka sa laser naghiusa sa abante teknolohiya sa laser nga adunay taas nga katukma nga mga sistema sa pagkontrol aron mahatagan ang talagsaon nga mga resulta sa pagmarka sa daghang mga industriya. Alang man sa metal nga pagkulit, plastik nga pagmarka, o pagkulit sa serial number, ang mga makina sa pagmarka sa laser hinungdanon sa mga industriya sama sa elektroniko, sakyanan, medikal nga mga himan, ug aerospace. Pinaagi sa hapsay nga paghiusa sa mga digital nga disenyo sa mga automated nga proseso sa pagmarka, kini nga mga makina naghatod sa tukma, lig-on nga mga marka nga makapauswag sa pagkasubay sa produkto, identidad sa brand, ug seguridad sa produkto.

Kinsa Naggamit ug Laser Marking Machine?

Mga makina sa pagmarka sa laser gigamit sa lainlaing mga industriya, lakip ang:

Mga tiggama sa elektroniko: Para sa pagmarka sa mga sangkap sama sa mga circuit board, semiconductors, ug microchips nga adunay mga logo, serial number, ug impormasyon sa produkto.

Industriya sa awto: Alang sa mga bahin sa makina, mga sangkap sa chassis, ug mga numero sa pag-ila sa sakyanan (VINs), diin ang pagmarka sa taas nga katukma hinungdanon.

Mga prodyuser sa medikal nga aparato: Para sa pagmarka mga implant, mga instrumento sa pag-opera, ug medikal nga packaging, pagsiguro sa pagsunod sa regulasyon ug pagsubay.

Aerospace: Para sa pagmarka nga kritikal mga bahin sa aerospace sama sa mga blades sa turbine, mga sangkap sa eroplano, ug impormasyon sa kaluwasan.

Mga retail ug consumer goods: Para sa pagkulit og mga logo, mga code sa produkto, ug mga ngalan sa brand ngadto mga produkto sa konsumidor ug alahas.

Unsa ang Laser Marking Machine?

A makina sa pagmarka sa laser mao ang usa ka high-tech nga himan nga naggamit sa usa ka naka-focus nga laser beam sa pagmarka o pagkulit sa mga materyales nga adunay taas nga katukma. Dili sama sa tradisyonal nga mga pamaagi sa pagkulit, ang pagmarka sa laser naggamit sa usa ka laser aron mabag-o ang nawong sa usa ka materyal, nga maghimo permanente ug taas nga mga marka sa kalainan. Ang proseso sa pagmarka sa laser naglakip sa kontrolado nga paggamit sa usa ka laser beam sa ibabaw sa usa ka materyal, nga maoy hinungdan sa materyal nga moagi sa pisikal o kemikal nga mga kausaban, nga naghimo sa usa ka lig-on nga marka.

Asa Kini Gigamit?

Ang mga makina sa pagmarka sa laser gigamit sa daghang mga industriya ug aplikasyon, lakip ang:

Pagkulit sa metal: Paghimo og taas nga kalainan serial number, mga logo, ug mga barcode sa metal ibabaw sama sa stainless steel, aluminyo, ug tumbaga.

Pagmarka sa plastik: Pagmarka plastik nga mga bahin sama sa mga kaso sa smartphone, mga botelya, ug medikal nga mga himan nga adunay permanente, taas nga panan-aw nga marka.

Pagkulit sa alahas: Pagmarka sa makuti nga mga disenyo, logo, ug mga detalye sa pag-personalize sa alahas ug mahal nga mga metal.

Pagputos ug pag-label: Pagmarka sa laser gigamit alang sa impormasyon sa produkto, batch code, ug barcode sa packaging sa mga konsumidor.

Pagkulit sa kahoy ug panit: Alang sa paghimo og pangdekorasyon o functional nga mga kinulit sa mga materyales sama sa kahoy, panit, ug kawayan.

Kanus-a Nahimong Importante ang Laser Marking Machines?

Uban sa paspas nga pag-uswag sa teknolohiya sa laser sa ulahing bahin sa ika-20 nga siglo, ang mga makina sa pagmarka sa laser nagsugod sa pag-ilis sa tradisyonal nga mga pamaagi sa pagmarka ug pagkulit sa lainlaing mga industriya. Ang panginahanglan alang sa taas nga katukma nga pagmarka, paspas nga mga oras sa pagbalhin, ug gamay nga kadaot sa mga materyales nagmaneho sa pagsagop sa mga sistema sa pagmarka sa laser, labi na sa taas nga gidaghanon sa mga palibot sa produksiyon sama sa paghimo sa elektroniko ug sakyanan.

Ngano nga Importante ang Laser Marking Machine?

Taas nga Katukma ug Detalye: Ang mga makina sa pagmarka sa laser naghatag ug dili hitupngan nga katukma, nga makahimo sa pagmarka bisan sa pinakagamay mga karakter, makuti nga mga disenyo, ug maayo mga detalye. Kini hinungdanon alang sa mga aplikasyon sama sa elektroniko, pagmarka sa medikal nga aparato, ug mga bahin sa aerospace, diin ang katukma mao ang kritikal.

Permanente ug Malungtaron nga mga Marka: Ang mga marka sa laser kay permanente ug makasugakod kaayo sa pagsul-ob, kaagnasan, ug pagkahanaw. Kini naghimo kanila nga sulundon alang sa mga industriya nga nanginahanglan ug dugay nga pag-ila, lakip na serial number ug mga logo sa trademark.

Dili-Kontak nga Proseso: Dili sama sa tradisyonal nga pamaagi sa pagmarka, ang pagmarka sa laser dili kontak, nagpasabut nga walay pisikal nga mga himan nga nalangkit. Kini nagwagtang sa risgo sa materyal nga deformation o kadaot, ilabi na sa pagmarka delikado nga mga materyales sama sa mga plastik o nipis nga mga metal.

Speed ug Efficiency: Ang mga makina sa pagmarka sa laser mahimong makamarka sa hilabihan ka paspas nga katulin, nga naghimo niini nga sulundon taas nga gidaghanon sa produksyon nga palibot. Ang abilidad sa pagmarka sa daghang mga bahin sa madali ug tukma nga pagtaas throughput ug kahusayan sa produksiyon.

Pagkadagaya: Ang mga makina sa pagmarka sa laser mahimong magamit sa lainlaing mga materyales, lakip ang mga metal, mga plastik, mga seramiko, bildo, ug kahoy. Kini nga versatility naghimo kanila nga angay alang sa usa ka halapad nga mga industriya ug aplikasyon.

Minimal nga Pagmentinar: Kung itandi sa mekanikal nga mga sistema sa pagkulit, ang mga makina sa pagmarka sa laser nagkinahanglan og gamay nga pagmentinar tungod sa ilang non-contact nga operasyon ug mas diyutay nga nagalihok nga mga bahin.

Giunsa Naglihok ang Laser Marking Machine?

Yugto sa Disenyo: Ang proseso sa pagmarka magsugod sa paghimo og digital design, kasagaran pinaagi CAD software. Mahimong kini usa ka logo, teksto, o bisan unsang uban pang naandan nga disenyo nga gikinahanglan alang sa pagmarka.

Pag-focus sa Laser Beam: Ang desinyo unya gi-convert ngadto sa usa ka set sa mga instruksyon (kasagaran sa porma sa G-code o uban pang mga compatible nga mga format) nga nagkontrol sa paglihok sa laser. Ang laser naka-focus sa ibabaw sa materyal sa usa ka tukma nga punto, uban sa gahum ug speed kontrolado sa paghimo sa gitinguha nga marka.

Proseso sa Pagmarka: Ang laser nagpagawas sa usa ka naka-focus nga sinag nga nakig-uban sa nawong sa materyal. Ang sagbayan maoy hinungdan sa nawong sa matunaw, alisngaw, o moagi ug kemikal nga reaksiyon, depende sa materyal. Naghimo kini og marka, nga mahimong gikan sa yano nga teksto hangtod sa komplikado nga mga imahe.

Pagpabugnaw ug Inspeksyon: Human ang laser moagi sa materyal, ang marka kusog nga mobugnaw. Ang katapusan nga produkto gisusi alang sa kalidad, pagsiguro nga ang marka nagtagbo sa gikinahanglan nga mga sumbanan alang sa pagkabasa ug kalig-on.

Post-Pagproseso: Sa pipila ka mga kaso, a panalipod nga taklap o uban pang mga pamaagi sa pagproseso pagkahuman mahimong magamit sa gimarkahan nga lugar, pagsiguro nga ang marka molungtad sa tibuuk nga kinabuhi sa produkto.

Mga Kaayohan sa Laser Marking Machines

Taas nga Kalidad nga mga Marka: Naghimo ang pagmarka sa laser hait, tin-aw, ug lig-on mga marka nga nagpabiling mabasa sa paglabay sa panahon, bisan ubos sa lisod nga mga kahimtang.

Minimal nga Distorsyon sa Materyal: Ang non-contact nga kinaiya sa proseso sa pagmarka sa laser nagpamenos sa risgo sa deformation, nga naghimo niini nga sulundon alang sa sensitibo nga mga materyales sama sa nipis nga mga metal o mga plastik.

Pagpahiangay: Gitugotan ang pagmarka sa laser alang sa personal nga mga marka o customized nga mga disenyo, nga naghimo niini nga usa ka popular nga pagpili alang sa branding ug pag-ila sa produkto sa mga industriya sama alahas ug mga butang sa konsumidor.

Mahigalaon sa kinaiyahan: Ang proseso sa pagmarka sa laser wala maglakip sa paggamit sa mga kemikal o mga tinta, nga naghimo niini nga usa ka eco-friendly nga alternatibo sa tradisyonal nga mga pamaagi sa pagmarka.

Gipamub-an ang mga Gasto sa Operasyon: Uban sa taas nga kahusayan ug ubos nga mga panginahanglanon sa pagmentinar, ang mga makina sa pagmarka sa laser makunhuran ang kinatibuk-ang gasto sa operasyon, nga nagtanyag sa dugay nga pagtipig ug taas nga pagbalik sa pamuhunan.

Panapos

Ang mga makina sa pagmarka sa laser nahimong usa ka hinungdanon nga himan sa modernong paghimo, pagtanyag taas nga katukma, paspas, ug episyente nga mga solusyon sa pagmarka alang sa mga industriya gikan sa elektroniko sa medikal nga mga himan ug aerospace. Uban sa ilang permanente nga marka, versatility, ug non-contact nga operasyon, kini nga mga makina makapahimo sa mga tiggama sa pagpauswag sa pagkasubay sa produkto, pagpalambo sa pag-ila sa brand, ug pagtagbo sa mga regulasyon sa industriya nga sayon.

Alang sa mga kompanya nga nagtinguha nga mapauswag ang pagka-produktibo samtang gipadayon ang kalidad sa produkto sa taas nga lebel, namuhunan sa usa ka makina sa pagmarka sa laser nagtanyag sa dili hitupngan nga mga benepisyo, lakip na ang pagkunhod sa materyal nga basura, high-speed nga produksyon, ug dugay nga resulta. Pagmarka man metal, plastik, seramiko, o kahoy, usa ka makina sa pagmarka sa laser usa ka kinahanglanon nga himan alang sa bisan unsang modernong linya sa produksiyon.