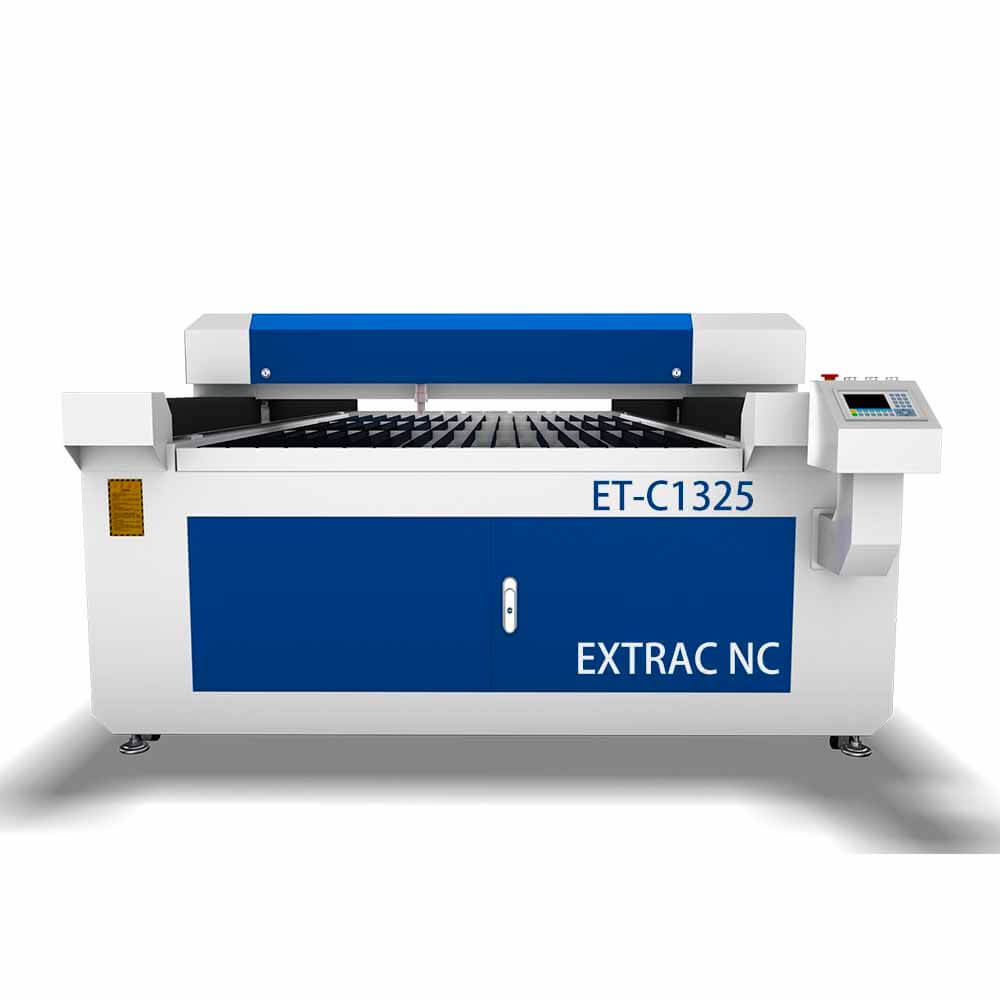

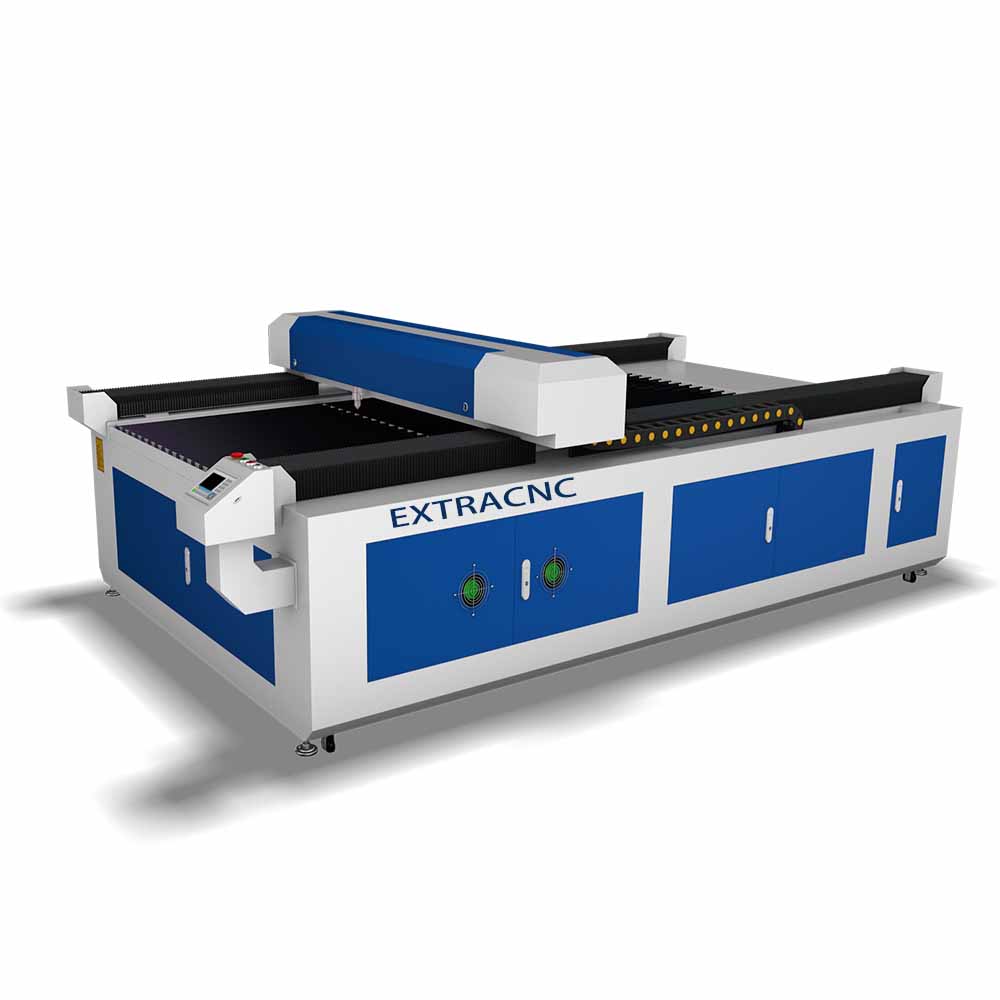

Laser Engraving Machine

A Laser Engraving Machine kay usa ka high-precision nga himan nga naggamit ug naka-focus nga laser beam aron pagkulit sa detalyadong mga disenyo, teksto, ug mga pattern ngadto sa lain-laing mga materyales sama sa kahoy, metal, bildo, plastik, ug panit. Kini nga teknolohiya nagtanyag talagsaon nga katukma ug katulin, nga naghimo niini nga sulundon alang sa mga industriya sama kostumbre nga mga regalo, signage, elektroniko, ug alahas. Dili sama sa tradisyonal nga mga pamaagi sa pagkulit, ang usa ka laser engraving machine makahimo og makuti nga mga disenyo nga walay direktang kontak sa materyal, nga moresulta sa limpyo, hait nga mga kinulit nga adunay gamay nga pagkaguba. Naghimo man og personalized nga mga regalo o naghimo ug custom nga promotional nga mga butang, ang laser engraving machine naghatag og dili hitupngan nga versatility, efficiency, ug abilidad sa paghimo og taas nga kalidad, detalyado nga mga engraving sa usa ka halapad nga mga materyales.

Laser Engraving Machine: Precision, Flexibility, ug Innovation alang sa Modernong Craftsmanship

A makina sa pagkulit sa laser nagkombinar sa cutting-edge nga teknolohiya uban sa high-precision motion control aron makahatag ug talagsaong resulta sa nagkalain-laing industriya, lakip na naandan nga pagkulit, personal nga mga regalo, produksyon sa signage, ug mga aplikasyon sa pagkulit sa industriya. Pinaagi sa hapsay nga paghiusa sa digital nga disenyo sa automated nga pagtangtang sa materyal, kini nga mga makina makahimo sa makuti nga pagkulit, pagmarka, ug pagputol, paghatag gahum sa mga artisan ug mga tiggama aron makab-ot ang taas nga kalidad, customized nga mga produkto nga adunay talagsaon nga katulin ug katukma.

Kinsa Naggamit ug Laser Engraving Machine?

Mga makina sa pagkulit sa laser kaylap nga gigamit sa mga propesyonal mga magkukulit, mga tighimog sign, mga tigdesinyo sa alahas, kostumbre nga mga tiggama sa regalo, ug serbisyo sa pagmarka sa bahin sa industriya. Mga industriya nga nagtutok sa personal nga pagkulit, naandan nga signage, ug branding sa produkto makabenepisyo og dako gikan sa versatility ug precision nga gitanyag niini nga mga sistema. Naghimo ka man og mga personal nga regalo, nagmugna og mga produkto nga pang-promosyon, o nagmarka sa mga bahin sa industriya nga adunay mga serial number o logo, ang makina sa pag-ukit sa laser usa ka kinahanglanon nga himan alang sa pagkab-ot sa taas nga kalidad nga mga resulta.

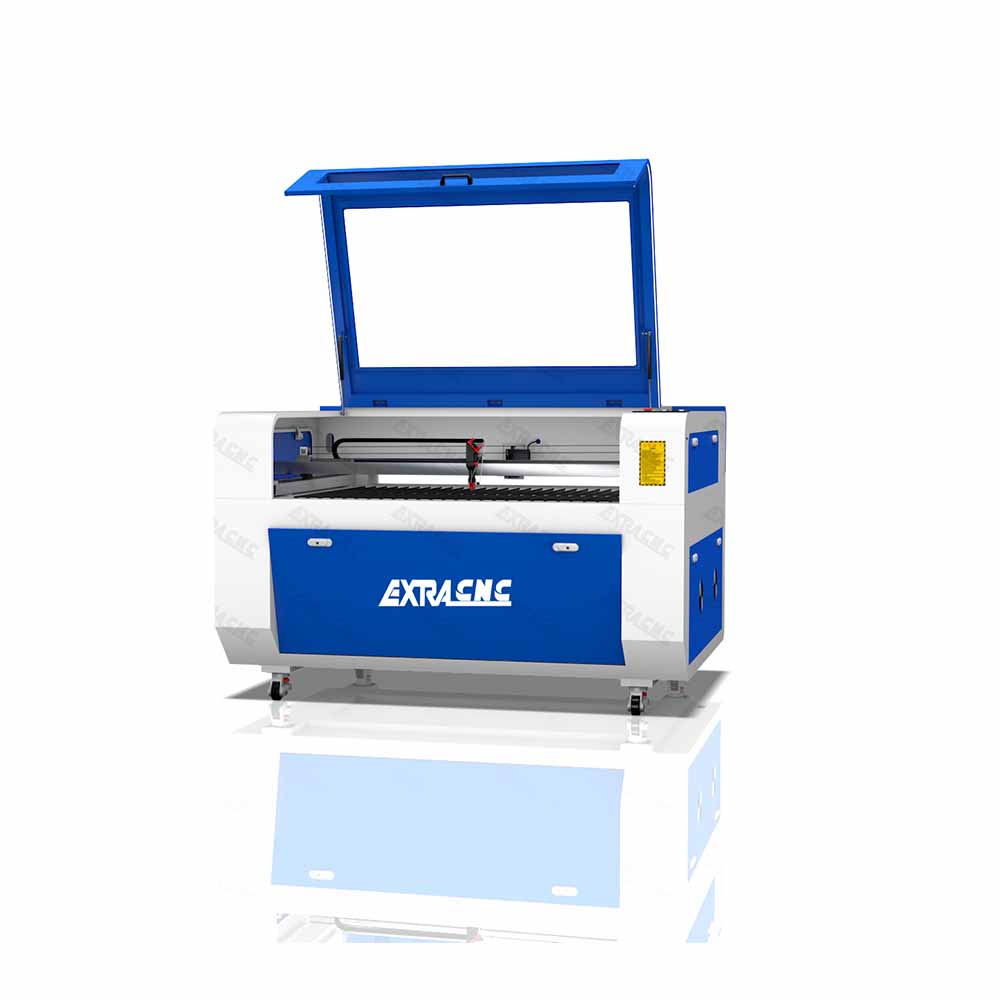

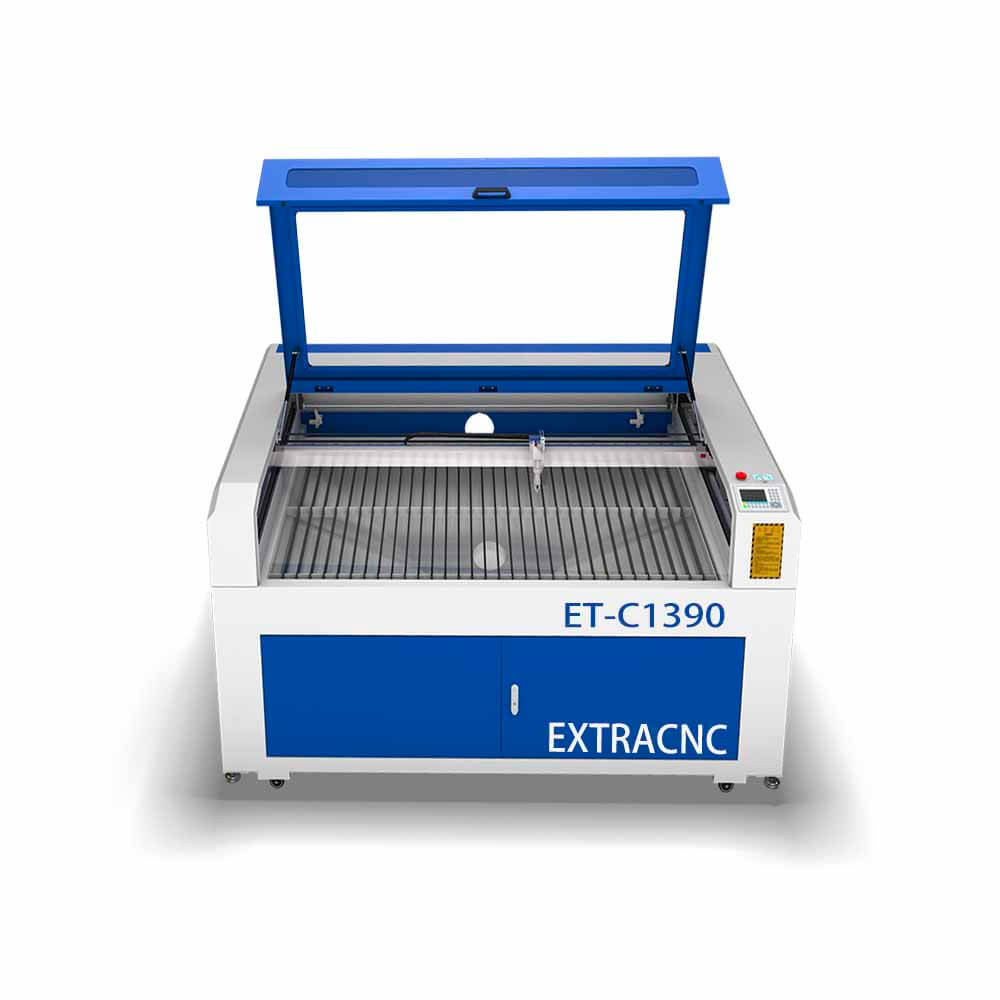

Unsa ang Laser Engraving Machine?

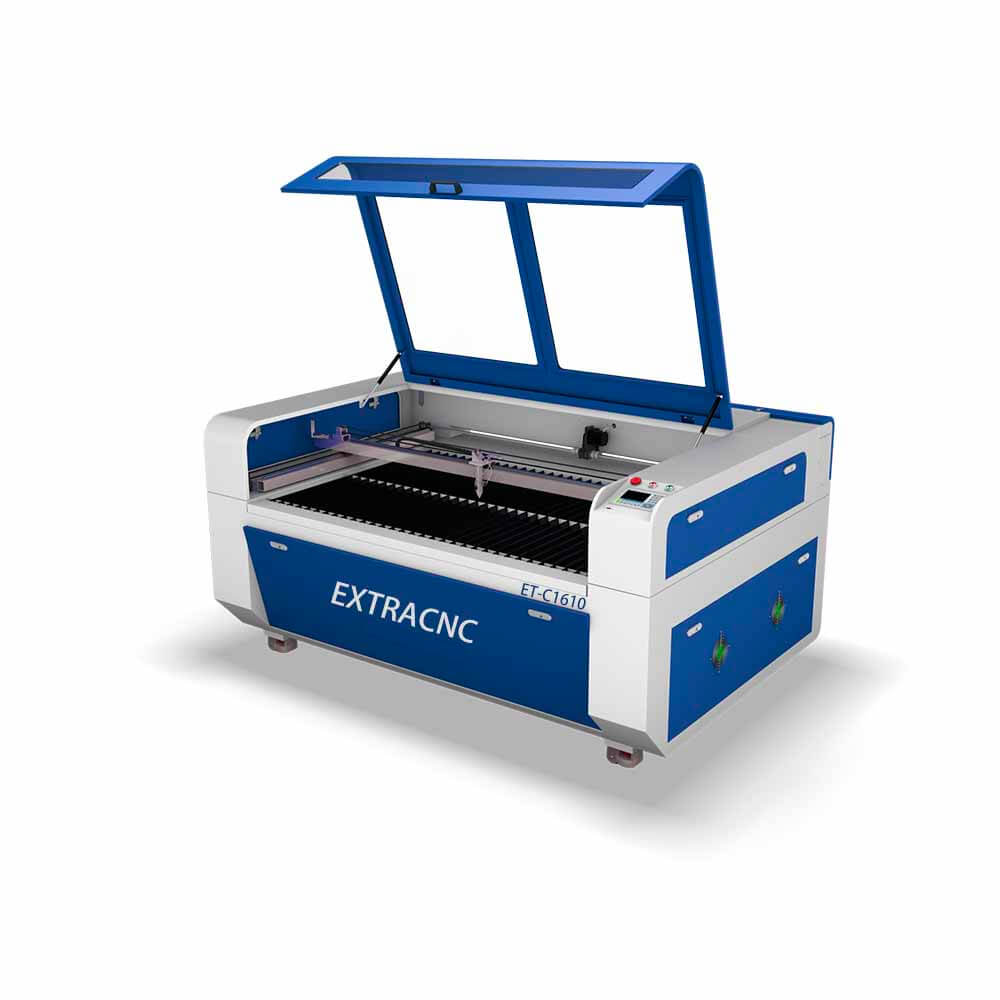

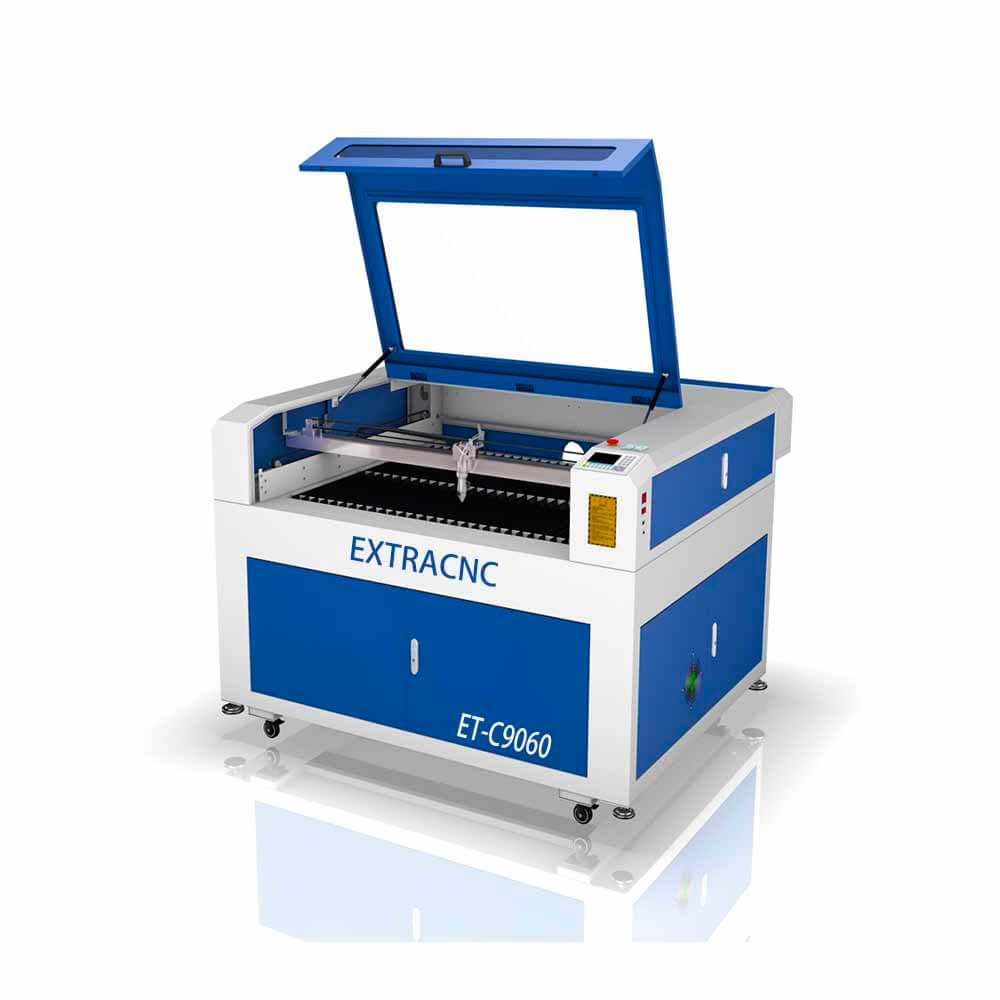

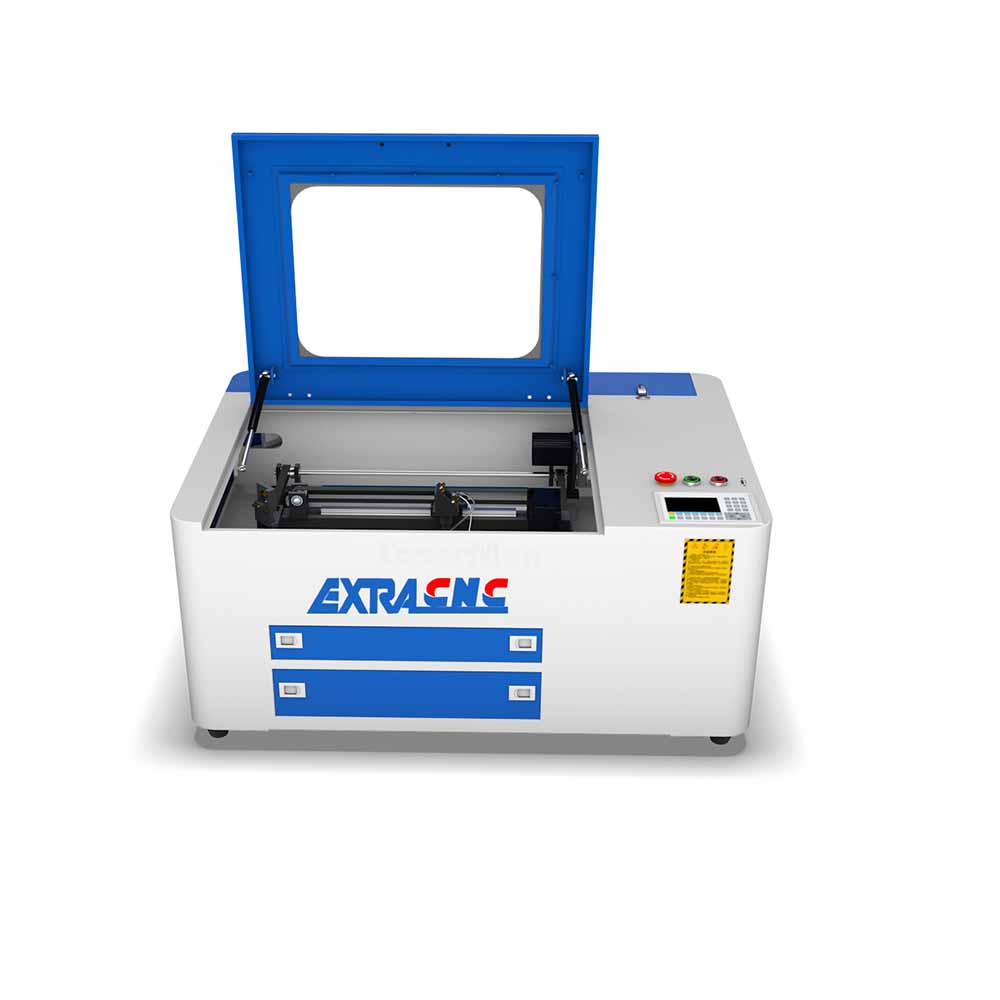

A makina sa pagkulit sa laser kay usa ka gamit nga kontrolado sa kompyuter nga naggamit ug naka-focus nga laser beam sa pag-etch sa mga disenyo sa lain-laing mga materyales, lakip na metal, kahoy, plastik, bildo, panit, ug mga seramiko. Ang makina nagtrabaho pinaagi sa pag-alisngaw sa ibabaw nga layer sa materyal, paghimo og permanente nga mga marka ug mga disenyo nga adunay taas nga katukma. Nahiusa sa Mga sistema sa pagkontrol sa CNC, ang ulo sa laser naglihok ubay sa daghang mga wasay (X, Y, Z), nga nagtugot alang sa makuti, detalyado nga mga disenyo nga masubli kaayo.

Asa Kini Gigamit?

Ang mga makina sa pag-ukit sa laser gigamit sa lainlaing mga industriya ug aplikasyon, lakip ang:

Personal nga regalo ug paghimo sa alahas: Paghimo ug custom engraving sa mga butang sama sa mga singsing sa kasal, mga kwintas, ug keychain.

Paggama og signage: Pagkulit og mga logo, mga ngalan sa negosyo, ug makuti nga mga disenyo alang sa duha sa sulod ug mga timailhan sa gawas.

Pagmarka sa bahin sa industriya: Pagmarka metal nga mga bahin, tooling, ug mga sangkap sa makina nga adunay mga barcode, serial number, o logo.

Woodworking ug crafts: Pagkulit og mga disenyong pangdekorasyon sa mga produkto sa kahoy sama sa muwebles, mga plake, ug buhat sa arte.

Mga ganti ug tropeyo: Pag-customize sa mga pasidungog, mga plake, ug mga tropeyo nga adunay mga kinulit alang sa mga seremonyas sa pag-ila ug mga kalihokan sa korporasyon.

Dekorasyon sa balay: Pagkulit sa makuti nga mga pattern o mga disenyo sa bildo, panit, ug uban pang mga materyales alang sa pinasahi nga mga butang sa balay.

Kanus-a Nahimong Kinahanglanon ang Laser Engraving Machines?

Ang mga makina sa pag-ukit sa laser nahimong mas popular sa ulahing bahin sa ika-20 nga siglo ingon nga mga pag-uswag sa teknolohiya sa laser ug Mga sistema sa pagkontrol sa CNC naghimo niini nga mga himan nga mas sayon ug episyente. Samtang ang panginahanglan mitubo alang sa customized nga mga produkto, personal nga mga kinulit, ug pagmarka sa bahin sa industriya, ang laser engraving machine nahimong kinahanglanon sa duha gamay nga artisan tindahan ug dagkong mga operasyon sa industriya.

Nganong Importante ang Laser Engraving Machine?

Taas nga Katukma ug Detalye: Ang mga makina sa pag-ukit sa laser nagtanyag ug talagsaong katukma, nga nagtugot sa makuti nga mga disenyo ug maayong mga detalye nga lisod o imposibleng makab-ot sa tradisyonal nga mga paagi sa pagkulit. Kini naghimo kanila nga sulundon alang sa pagkulit sa maayong arte, custom nga mga logo, ug detalyado nga branding sa produkto.

Versatility ug Flexibility: Ang mga makina sa pag-ukit sa laser mahimong magamit sa daghang mga materyales, lakip ang kahoy, metal, bildo, acrylic, panit, ug bato. Kini nga pagpahiangay nagtugot sa mga negosyo sa pag-diversify sa ilang mga gitanyag nga produkto ug pag-atiman sa lainlaing mga bahin sa merkado.

Speed ug Efficiency: Ang pag-automate sa mga proseso sa pagkulit makapakunhod pag-ayo sa oras ug trabaho nga gikinahanglan alang sa manwal nga pagkulit, nga makapahimo taas nga gidaghanon sa produksyon uban ang makanunayon nga mga resulta. Kini labi ka mapuslanon sa mga industriya sama sa personal nga mga regalo, naandan nga signage, ug mass-production nga pagkulit.

Pagka-epektibo sa Gasto: Ang mga makina sa pag-ukit sa laser epektibo sa gasto sa kadugayan tungod kay nakunhuran nila ang materyal nga basura, nanginahanglan gamay nga pagmentinar kung itandi sa tradisyonal nga mga pamaagi sa pagkulit, ug labi nga nagdugang ang kahusayan sa produksiyon. Ang ubos nga gasto sa operasyon ug taas nga return on investment (ROI) paghimo kanila nga usa ka popular nga pagpili alang sa gagmay nga mga negosyo ug dagkong mga negosyo.

Giunsa Naglihok ang Laser Engraving Machine?

Yugto sa Disenyo: Ang mga proyekto gihimo gamit ang CAD (Computer-Aided Design) software. Kung kini usa ka personal nga pagkulit sa usa ka regalo o usa ka komplikado nga disenyo alang sa pagmarka sa bahin sa industriya, ang disenyo sa CAD mao ang pundasyon sa tibuuk nga proseso.

Pagprograma sa CAM: Kung nahuman na ang disenyo, i-import kini sa CAM (Computer-Aided Manufacturing) software, nga naghubad sa disenyo ngadto sa usa ka serye sa mga instruksyon, kasagaran sa G-code. Kini nga mga panudlo nagdiktar sa mga lihok sa ulo sa laser sa panahon sa proseso sa pagkulit.

Pag-setup sa Materyal: Ang materyal nga ikulit gibutang sa ibabaw sa trabaho, kasagaran sa tabang sa a vacuum nga lamesa o mga clamp sa paghawid niini sa dapit. Kini nagsiguro nga ang materyal magpabilin nga lig-on sa panahon sa proseso sa pagkulit.

Proseso sa Pagkulit: Ang ulo sa laser naglihok subay sa X, Y, ug Z axes, nga nagpunting sa laser beam sa ibabaw sa materyal. Ang sagbayan moalisngaw sa ibabaw nga layer sa materyal, nga nagbilin ug permanenteng marka o pagkulit.

Post-Pagproseso: Human sa pagkulit, pipila ka mga materyales mahimong magkinahanglan og post-processing, sama sa pagpanglimpyo, pagpasinaw, o pagtapos aron mapalambo ang hitsura sa katapusan nga produkto ug masiguro nga ang pagkulit klaro ug tukma.

Mga Kaayohan sa Laser Engraving Machines

Katukma ug Katukma: Ang pag-ukit sa laser naghatag ug talagsaong detalye ug katin-aw, nga hinungdanon alang sa mga industriya nga nanginahanglan ug taas nga lebel sa katukma, sama sa pagkulit sa alahas, kostumbre nga mga awards, ug pagmarka sa serial number.

Ubos nga Materyal nga Basura: Ang naka-focus nga kinaiya sa laser beam nagpamenos sa materyal nga basura, nga naghimo sa laser engraving nga mas malungtaron ug cost-effective nga kapilian kon itandi sa tradisyonal nga mga pamaagi sa pagkulit.

Dili Kinahanglan ang Pisikal nga Pagkontak: Tungod kay ang laser beam dili pisikal nga makahikap sa materyal, walay pagsul-ob sa makina, ug ang materyal dili kaayo madaot sa panahon sa proseso sa pagkulit.

Pagkapasibo: Ang mga makina sa pag-ukit sa laser kay daghag gamit ug makagama ug mga custom nga disenyo sa lain-laing mga materyales, nga magtugot sa walay kataposang mga posibilidad sa pag-personalize sa produkto ug pagmarka.

Paspas nga Oras sa Pag-usab: Ang pag-automate sa proseso sa pagkulit makapahimo sa dali nga mga oras sa pag-usab alang sa gagmay ug dagkong mga batch, nga hinungdanon sa paspas nga industriya sama sa naandan nga paghimo sa regalo, pang-promosyon nga mga produkto, ug pagmarka sa bahin sa industriya.

Panapos

Ang mga makina sa pag-ukit sa laser nagbag-o sa kalibutan sa naandan nga pagkulit ug personal nga mga produkto. Uban sa ilang abilidad sa paghatud sa taas nga katukma nga mga pagkulit sa madali ug epektibo nga gasto, kini nga mga makina kinahanglanon sa mga industriya gikan sa disenyo sa alahas sa industriyal nga pagmarka ug naandan nga paghimo sa signage. Ang pagka-flexible, paspas, ug katukma nga gitanyag sa mga makina sa pag-ukit sa laser naghimo kanila nga usa ka hinungdanon nga himan alang sa mga negosyo nga nagtan-aw sa paghimo og taas nga kalidad, gipahiangay nga mga produkto samtang gipadako ang kahusayan ug ganansya.

Kung naa ka naandan nga paghimo sa regalo, industriyal nga pagmarka, o mamugnaon nga arte, a makina sa pagkulit sa laser naghatag sa versatility ug tukma nga gikinahanglan aron makab-ot ang talagsaon nga mga resulta.