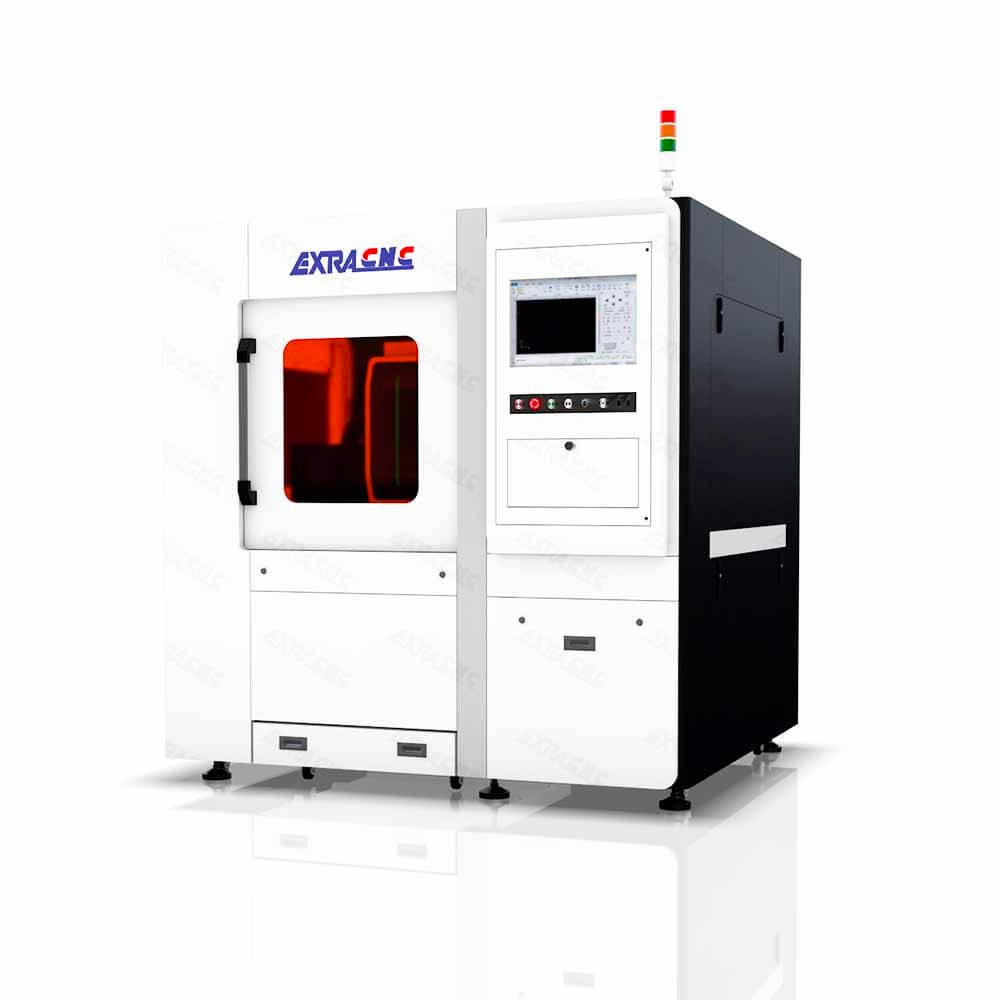

EXTRA CNC Laser Cutting MACHINE FACTORY SUPPLIER

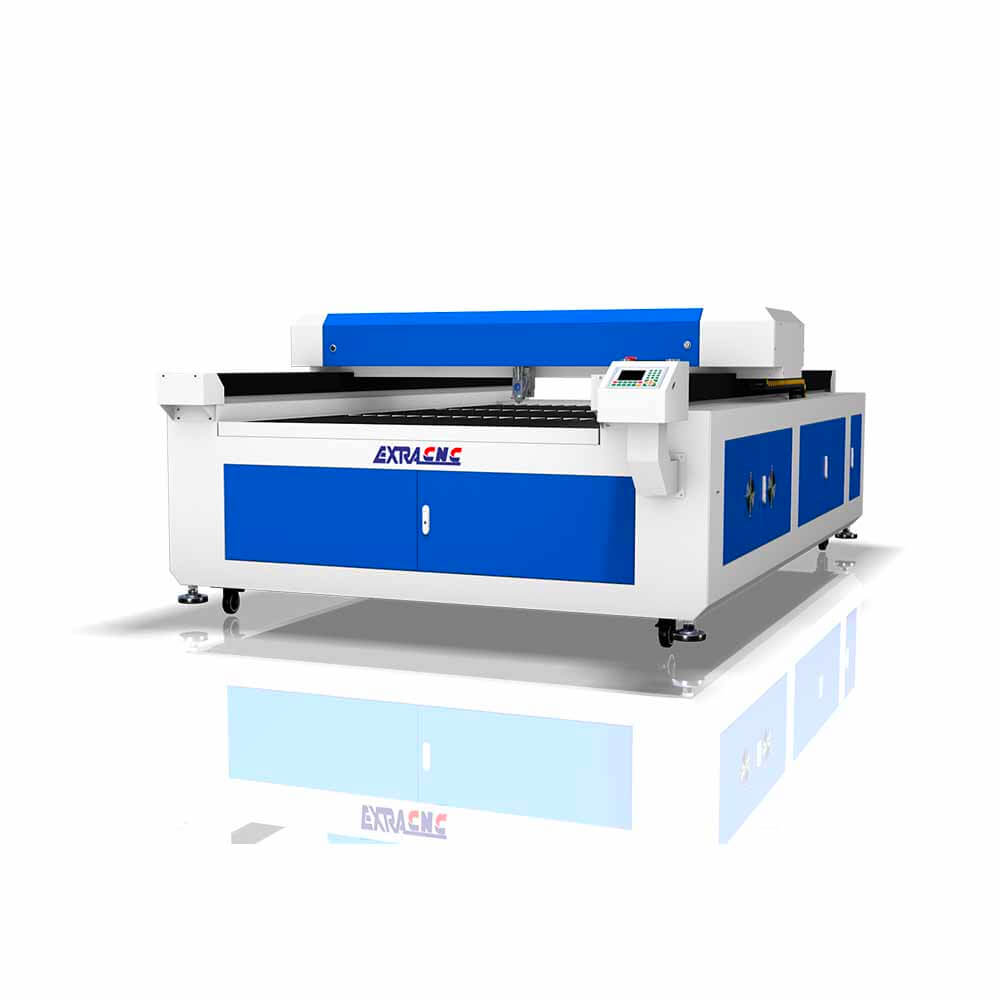

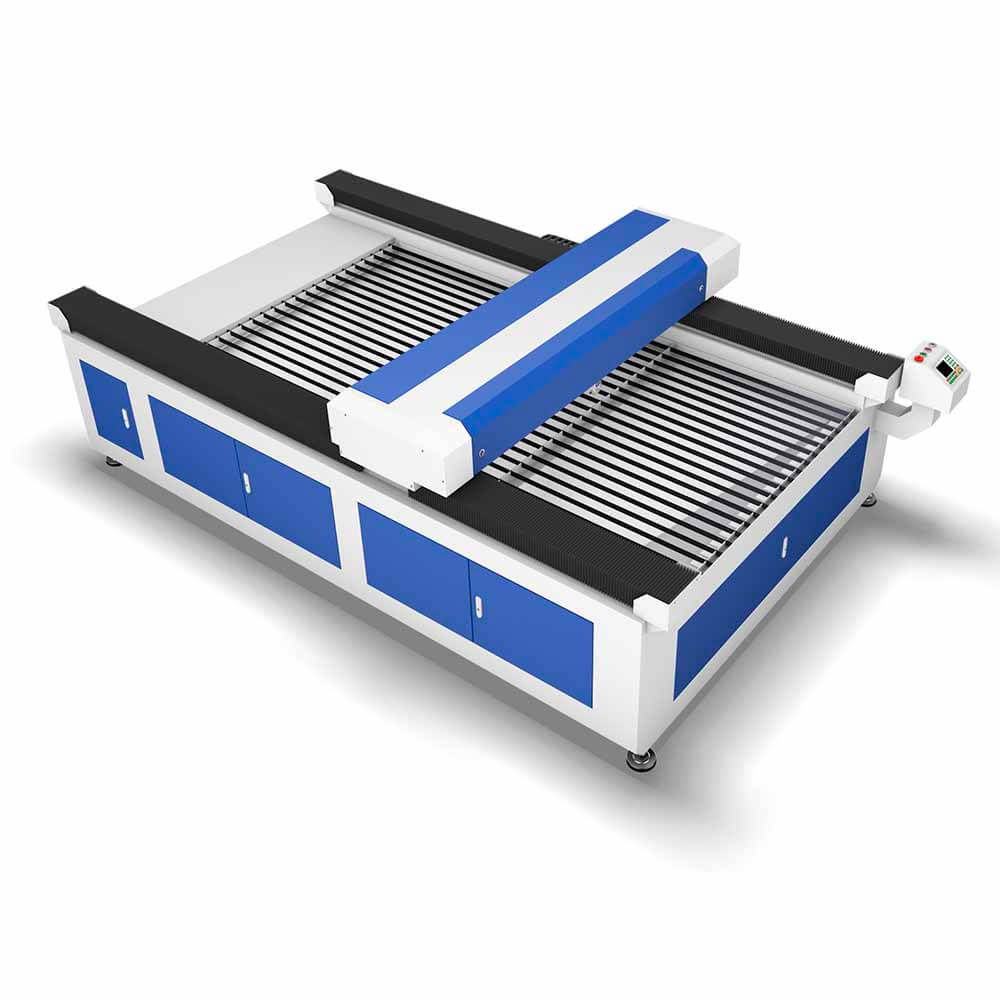

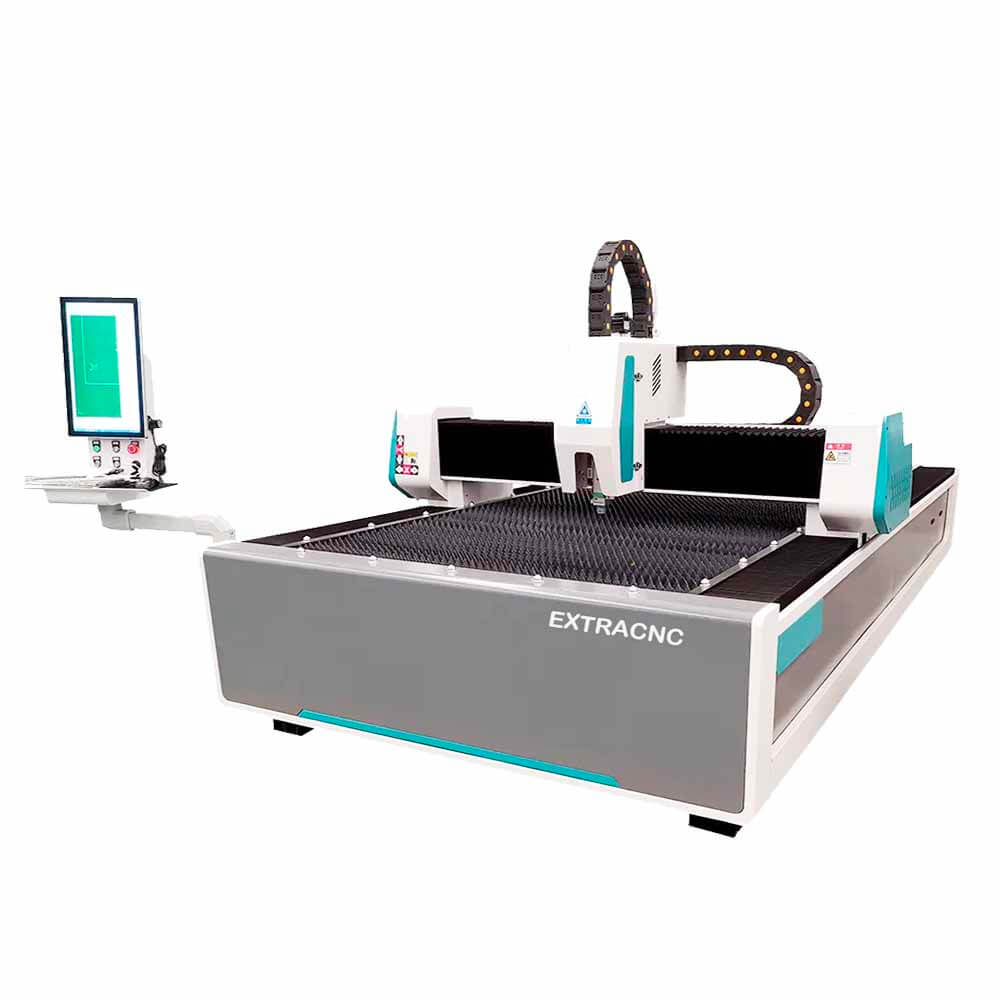

A laser cutting machine maoy usa ka state-of-the-art nga himan nga naggamit ug usa ka laser beam nga naka-focus kaayo sa pagputol, pagkulit, ug pagmarka sa nagkalain-laing mga materyales nga adunay dili hitupngan nga katukma. Kini nga advanced nga teknolohiya kaylap nga gigamit sa mga industriya sama sa metalworking, sakyanan, aerospace, elektroniko, ug signage tungod sa abilidad niini sa paghimo og limpyo, tukma nga pagputol nga adunay gamay nga basura. Ang mga laser cutter makahimo sa pagdumala sa lainlaing mga materyales, lakip na metal, plastik, kahoy, acrylic, mga komposisyon, ug bisan mga seramiko, nga naghimo kanila nga labi ka daghang gamit alang sa lainlaing mga aplikasyon. CO2 laser cutting machines kasagarang gigamit alang sa mga dili metal sama sa kahoy ug plastik, samtang fiber laser cutter maayo sa pagputol sa mga metal sama sa stainless steel, aluminyo, ug tumbaga. Ang katukma sa usa ka laser cutting machine nagtugot alang sa makuti nga mga disenyo ug hugot nga pagtugot, pagsiguro sa taas nga kalidad nga mga resulta alang sa naandan nga paghimo, prototyping, ug mass production. Uban sa mga benepisyo sama sa mas paspas nga mga oras sa pagproseso, labing maayo nga kalidad sa sulud, ug pagkunhod sa basura nga materyal, ang mga makina sa pagputol sa laser nahimo nga solusyon alang sa mga industriya nga nangita kaepektibo, pagka-flexible, ug taas nga katukma sa ilang mga proseso sa paghimo.

Laser Cutting Machine: Katukma ug Episyente alang sa Modernong Paggama

Ang usa ka laser cutting machine naghiusa sa abante nga teknolohiya nga adunay high-precision motion control aron makahimo og talagsaon nga mga resulta sa nagkalain-laing mga industriya, lakip ang metal fabrication, automotive, aerospace, ug signage. Pinaagi sa hapsay nga paghiusa sa digital nga disenyo sa automated nga pagtangtang sa materyal, kini nga mga makina makahimo sa tukma nga pagputol, pagkulit, ug makuti nga pagmugna sa sumbanan, paghatag gahum sa mga tiggama aron makab-ot ang labaw nga kalidad, katulin, ug kaepektibo sa gasto.

Kinsa Naggamit ug Laser Cutting Machine?

Ang mga propesyonal nga tiggama, metal fabricators, sign makers, automotive suppliers, ug designers nagsalig sa laser cutting machines aron makab-ot kanunay ang taas nga kalidad nga mga resulta. Mga industriya sama sa pagproseso sa metal, paghimo sa mga piyesa sa awto, aerospace engineering, ug naandan nga paghimo sa signage ilabina nga nakabenepisyo gikan sa katukma, pagkasubli, ug pagkadaiya niini nga mga sistema.

Unsa ang Laser Cutting Machine?

Ang laser cutting machine kay usa ka advanced, computer-controlled nga device nga gi-engineered sa pagputol ug pagkulit sa nagkalain-laing mga materyales, lakip na ang mga metal, plastik, kahoy, ug mga composite. Gamit ang gipunting nga laser beam, ang makina matunaw, masunog, o mag-alisngaw sa materyal subay sa gitakda nang daan nga mga agianan aron makamugna og makuti nga mga porma ug disenyo. Ang integrated CNC controller nag-orkestra sa mga lihok subay sa daghang mga axes (kasagaran X, Y, ug Z), nagtugot alang sa tukma nga pagputol, pagkulit, ug bisan sa pagbuslot sa komplikadong mga pattern.

Asa Kini Gigamit?

Ang mga makina sa pagputol sa laser gigamit sa daghang lainlaing mga setting sa industriya ug komersyal, lakip ang:

Paggama sa metal: Pagputol sa steel, aluminum, brass, ug stainless steel sheets para sa industriyal nga mga component, structural materials, ug custom designs.

Industriya sa awto: Tukma nga pagputol sa mga parte sa metal, sangkap sa lawas, ug mga parte sa makina.

Industriya sa aerospace: Pagputol ug pagkulit sa komplikadong mga sangkap nga adunay taas nga katukma aron makab-ot ang higpit nga mga sumbanan sa kalidad.

Signage ug pangdekorasyon nga produksyon: Laser engraving logo, disenyo, ug makuti nga mga pattern sa lain-laing mga materyales alang sa komersyal ug pangdekorasyon nga signage.

Prototyping ug pagpalambo sa produkto: Paghimo paspas nga mga prototype ug gamay nga batch nga produksiyon alang sa mga katuyoan sa panukiduki ug kalamboan.

Kanus-a Nahimong Kinahanglanon ang Laser Cutting Machines?

Ang teknolohiya sa pagputol sa laser mitumaw sa 1960s ug dali nga nakakuha sa kaylap nga paggamit tungod sa katukma ug kahusayan niini. Sulod sa mga dekada, ang mga pag-uswag sa teknolohiya sa laser ug mga sistema sa pagkontrol sa CNC nahimo mga makina sa pagputol sa laser kinahanglanon sa mga industriya nga nanginahanglan high-speed, high-precision cutting. Karon, kritikal sila sa naandan nga paghimo, paspas nga prototyping, ug mass production mga aplikasyon.

Nganong Importante ang Laser Cutting Machine?

Gipauswag nga Katukma ug Kalidad: Ang mga makina sa pagputol sa laser naghatag og hilabihan ka taas nga katukma, nga adunay gamay nga lebel sa pagtugot, nga naghimo kanila nga sulundon alang sa mga industriya nga nagkinahanglan og hugot nga mga espesipikasyon, sama sa aerospace, sakyanan, ug metalworking.

Dugang nga Speed ug Efficiency: Ang automation nga gihatag sa mga sistema nga kontrolado sa CNC nagtugot alang sa paspas nga mga siklo sa produksiyon, pagkunhod sa manual nga pagtrabaho ug mga oras sa pag-setup-mga yawe nga bentaha sa taas nga gidaghanon sa paghimo ug custom cutting nga mga aplikasyon.

Versatility ug Flexibility: Ang mga tigputol sa laser makahimo sa pagproseso sa usa ka halapad nga mga materyales, lakip na stainless steel, aluminyo, plastik, ug kahoy, nga makapahimo sa mga tiggama sa pag-diversify sa ilang mga gitanyag nga produkto ug pagpahiangay sa lain-laing mga panginahanglan sa merkado.

Pagka-epektibo sa Gasto: Pinaagi sa pagkunhod sa materyal nga basura, pagpausbaw sa pagputol katukma, ug pagdugang sa produksyon speed, laser cutting machines nagtanyag sa usa ka taas nga pagbalik sa puhunan alang sa mga tiggama, nagtabang sa pagpakunhod sa gasto ug pagdugang sa ganansya sa gagmay ug dagkong mga operasyon.

Giunsa ang Paglihok sa Laser Cutting Machine?

Yugto sa Disenyo: Ang mga detalyadong proyekto kay gikonsepto gamit CAD software, paghimog makuti nga mga disenyo—para sa pagputol sa metal nga mga sangkap, pagkulit sa mga logo, o paghimog custom nga mga piyesa.

Pagprograma sa CAM: Ang disenyo sa CAD gi-import ngadto sa CAM software, nga nag-convert sa disenyo ngadto sa mga toolpath, nga gipahayag ingon G-code o M-code. Kini nga kodigo nagdiktar sa tukma nga paglihok sa ulo sa laser, nga naggiya niini subay sa X, Y, ug Z nga mga axes alang sa pagputol, pagkulit, o pagbuslot.

Pag-setup sa Materyal: Ang materyal nga lig-on nga gibutang sa ibabaw sa trabaho nawong, sa kasagaran sa paggamit sa usa ka vacuum nga lamesa o sistema sa pag-clamping, pagsiguro sa kalig-on sa panahon sa proseso sa pagputol sa laser.

Proseso sa Pagputol: Gigiyahan sa CNC controller, ang laser head naglihok subay sa gitakda nang daan nga mga toolpath. Ang laser beam naka-focus sa materyal, pag-alisngaw o pagtunaw niini aron makab-ot ang limpyo, detalyado nga pagputol.

Post-Pagproseso: Pagsunod sa proseso sa pagputol, post-processing nga mga lakang sama sa pag-deburring, sanding, o pagpintal mahimong magamit aron mapalambo ang katapusan nga pagkahuman ug masiguro ang kalidad sa mga sangkap nga giputol.

Mga Kaayohan sa Laser Cutting Machines

Katukma ug Katukma: Ang teknolohiya sa pagputol sa laser nagtanyag og dili hitupngan nga katukma, nga nagtugot sa mga tiggama sa pagkab-ot sa makuti nga mga pagtibhang ug komplikadong mga geometries nga adunay katukma nga lebel sa micron.

Gipamenos nga Materyal nga Basura: Tungod sa naka-focus nga kinaiya sa laser, ang materyal nga basura gipakunhod, nga mosangpot sa pagdaginot sa gasto sa materyal nga gasto.

Flexible ug Napasibo: Ang mga laser cutter makahimo sa pagdumala sa lain-laing mga materyales ug mga gibag-on, nga naghimo kanila nga angay alang sa prototyping ug mass production run.

Ubos nga Pagmentinar: Ang mga makina sa pagputol sa laser sa kasagaran nagkinahanglan og gamay nga pagmentinar kay sa tradisyonal nga mekanikal nga mga makina sa pagputol, pagpamenos sa downtime ug pagdugang sa produktibo.

Panapos

Gibag-o sa mga makina sa pagputol sa laser ang paagi sa pagduol sa mga tiggama sa pagputol, pagkulit, ug paggama sa katukma. Uban sa ilang abilidad sa paghatod taas nga katukma nga mga resulta sa madali ug sa episyente, laser cutters mao ang usa ka kinahanglan-adunay sa mga industriya sama sa paghimo sa metal, paghimo sa awto, ug produksyon sa signage. Ang ilang pagka-flexible, pagka-epektibo sa gasto, ug taas nga katukma paghimo kanila nga gikinahanglan nga mga himan alang sa modernong mga operasyon sa paggama.

Kung nangita ka nga magputol stainless steel, aluminyo, o kahoy, ang usa ka laser cutting machine mao ang sulundon nga solusyon alang sa pagpauswag sa katukma, katulin, ug kahusayan sa imong mga proseso sa produksiyon.