EXTRA CNC MACHINE FACTORY SUPPLIER

Discover precision and performance with EXTRA CNC’s 2025 industrial-grade CNC router machines — engineered for scalable production across woodworking, metal fabrication, plastics, composites, and more. From compact 2×2 ft to heavy-duty 6×12 ft models, plus fully customizable worktables, our advanced 3-axis, 4-axis, and 5-axis CNC routers meet every business need, from startups to high-volume manufacturers. Featuring rotary attachments, 360° multi-axis machining, IoT-ready control systems, automated tool changers, and upgradeable spindles, EXTRA CNC routers offer superior accuracy, energy efficiency, and seamless CAD/CAM integration. Future-proof your production with durable, ISO-certified machines, expert technical support, and smart automation designed for Industry 4.0. Whether you’re cutting, carving, engraving, or prototyping, EXTRA CNC delivers the perfect CNC router solution to help you reduce waste, minimize downtime, and scale your business. Request a free quote today and experience reliable, high-performance CNC routing tailored for modern manufacturing.

A 5-axis CNC router is a cutting-edge, computer-controlled subtractive machining system designed for multi-directional cutting and simultaneous five-axis contouring with outstanding precision. Unlike 3D printers, this advanced router combines three linear axes (X, Y, Z) with two rotational axes (A, B/C) to enable compound-angle machining on complex surfaces. Built with a robust gantry structure, rotary table, servo-driven actuators, and high-rigidity linear rails, it offers exceptional stability and flexibility for diverse applications. Ideal for shaping materials like wood, acrylic, thermoplastics, non-ferrous metals, and composites, the 5-axis CNC router is widely used for aerospace-grade components, precision mold fabrication, automotive prototypes, and high-tolerance industrial parts.

A 4-axis CNC router is an advanced computer-controlled machining tool built upon the foundation of a standard 3-axis CNC machine, with the added capability of a fourth rotary axis. This rotary axis allows the spindle to rotate up to 180 degrees along either the X-axis or Y-axis, enabling precision 3D arc milling, complex surface carving, and curved edge cutting. A 4-axis CNC machine enhances traditional flat sheet cutting and relief engraving by adding the flexibility to perform cylindrical machining, round column carving, and multi-sided part milling. Widely used in woodworking, sign-making, mold making, furniture production, and prototype manufacturing, a 4th axis CNC router combines versatility and accuracy for both flat and 3D applications. Whether you’re crafting decorative relief panels, sculpting intricate 3D statues, or turning cylindrical workpieces, the 4-axis CNC router delivers reliable, automated performance with computer numerical control for smooth, detailed, and efficient cutting.

A CNC wood router is a fully automated computer-controlled cutting machine designed for woodworking tasks such as cutting, engraving, drilling, and slotting based on 2D or 3D designs created in CAD/CAM software. This type of CNC machine is built from essential components including a sturdy machine frame, high-speed spindle motor, T-slot or vacuum worktable, vacuum pump system, CNC controller, motor drivers, linear guide rails, rack and pinion system, ball screw drive, power unit, limit sensors, collets, cutting tools, and a range of accessories. CNC wood routers are available in various configurations, including 3-axis, rotary 4th axis, full 4-axis, and advanced 5-axis woodworking machines. Popular table sizes range from compact models like 2×3 feet and 2×4 feet to larger formats such as 4×4 feet, 4×6 feet, 4×8 feet, 5×10 feet, and 6×12 feet. CNC wood routers are widely used across the woodworking industry for projects like cabinet production, wooden door carving, custom signage, fine art pieces, furniture crafting, and decorative home accents, offering precise, efficient, and repeatable machining for both hobbyists and professionals.

An ATC CNC router is an advanced computer-controlled woodworking machine equipped with an automatic tool changer system, designed to switch router bits and cutting tools from a preloaded tool magazine without manual intervention. This smart automation enhances production efficiency and accuracy when handling complex and multi-step designs. Commonly used in woodworking applications such as cabinet production, door carving, furniture manufacturing, signage creation, arts and crafts, decorative wood panels, and musical instrument crafting, the ATC CNC router is ideal for both mass production and custom projects. The ATC spindle typically works with tool magazines holding 4, 6, 8, 10, or 12 different router bits and cutting tools, allowing smooth transitions between drilling, cutting, grooving, and carving tasks. ATC systems are available in several configurations including linear-type tool changers, rotary drum-style tool changers, and chain-type tool changers, all designed to reduce downtime and maximize workflow efficiency in CNC woodworking, sign making, and panel processing industries.

A hobby CNC router kit is a compact, precision-driven machine tool specifically designed for DIY enthusiasts, makers, and small business owners working from home workshops or limited spaces. This type of CNC machine operates by following tool paths created through CAD/CAM software, allowing users to cut, engrave, and shape materials based on pre-designed 2D or 3D models. Hobby CNC routers are often equipped with a DSP handheld controller or PC-based CNC control systems, offering excellent compatibility with popular design software like ArtCAM, Type3, CastMate, and UG. Available in desktop, benchtop, and tabletop configurations, these machines are lightweight, portable, and ideal for flexible workspace setups. A hobby CNC router is widely used for crafting personalized signs, decorative logos, carved letters, artistic reliefs, custom molds, and creative crafts from a variety of materials including wood, MDF, plywood, bamboo, acrylic, plastics, foam, and soft metals like aluminum, copper, and brass, making it a versatile and efficient solution for small-scale production and creative design projects.

ChatGPT said:

A CNC foam router is a specialized computer-controlled cutting machine designed for milling large foam blocks, wood, or aluminum workpieces with high precision. Unlike oversized wood routers, foam CNC machines are built to industrial-grade standards in both mechanical design and electronic control, offering performance similar to a light-duty CNC gantry milling machine. Widely used across industries like mold making (lost foam, foundry patterns, aluminum casting molds), custom EPS/EVA molding, foam sculpture, 3D polystyrene shapes, props, statues, and rapid prototyping, CNC foam routers ensure smooth and accurate cutting. Available in 3 axis, 4 axis, and 5 axis configurations, these machines can handle various materials including polystyrene, wood, and aluminum, meeting the demands of both artistic and industrial production.

A Nesting CNC router machine is an advanced, computer-controlled woodworking solution designed for efficient panel processing, combining nesting, loading, cutting, drilling, and grooving into one streamlined system. Equipped with an intelligent CNC control system, this automatic cutting machine is widely used in custom furniture manufacturing, enabling seamless production of cabinet parts, shelves, doors, and decorative panels. The workflow starts with CAD design software to create detailed 2D or 3D layouts, while CAM software generates G-code instructions to guide the CNC router through precision cutting, shaping, and machining tasks. The machine moves its gantry via stepper or servo motors, while the high-speed spindle handles material cutting with accuracy and stability. Nesting CNC routers are available in single-head, dual-head, triple-head, and four-head models depending on spindle configurations, and feature single worktables, dual worktables, or moving table structures to optimize productivity. These versatile smart CNC machines can be fully customized to suit personalized woodworking projects, making them ideal for producing tailored kitchen cabinets, bathroom vanities, wardrobes, wall units, storage cabinets, pantry units, and other furniture solutions. In addition to cabinetry, this CNC wood router can also handle interior doors, office furniture, home decor panels, and commercial fixtures, offering manufacturers high-precision, scalable production for both mass customization and small-batch orders.

A 3D CNC router machine is a high-precision, computer-controlled cutting and carving system designed for three-dimensional machining on a wide variety of materials. Powered by an advanced 3D CNC control system, this router is capable of performing complex 2D engraving, 3D relief carving, surface cutting, and precision milling across different substrates such as wood, plastic, foam, composites, and soft metals. The machine operates through three main coordinate axes: the X-axis (horizontal left to right), Y-axis (horizontal front to back), and Z-axis (vertical up and down), which together create a true 3D motion path for dynamic machining. When an additional axis is integrated, it becomes a 4 axis CNC router — this can either be a rotary axis for cylindrical 3D carving and tube milling, or a swing axis designed for 180-degree multi-angle engraving. For even more advanced capabilities, adding two more rotational axes transforms the setup into a 5 axis CNC router, enabling full 360-degree multi-face machining, undercutting, and complex 3D model shaping, making it ideal for industrial applications like mold making, sculpture, aerospace parts, furniture prototypes, and artistic fabrication.

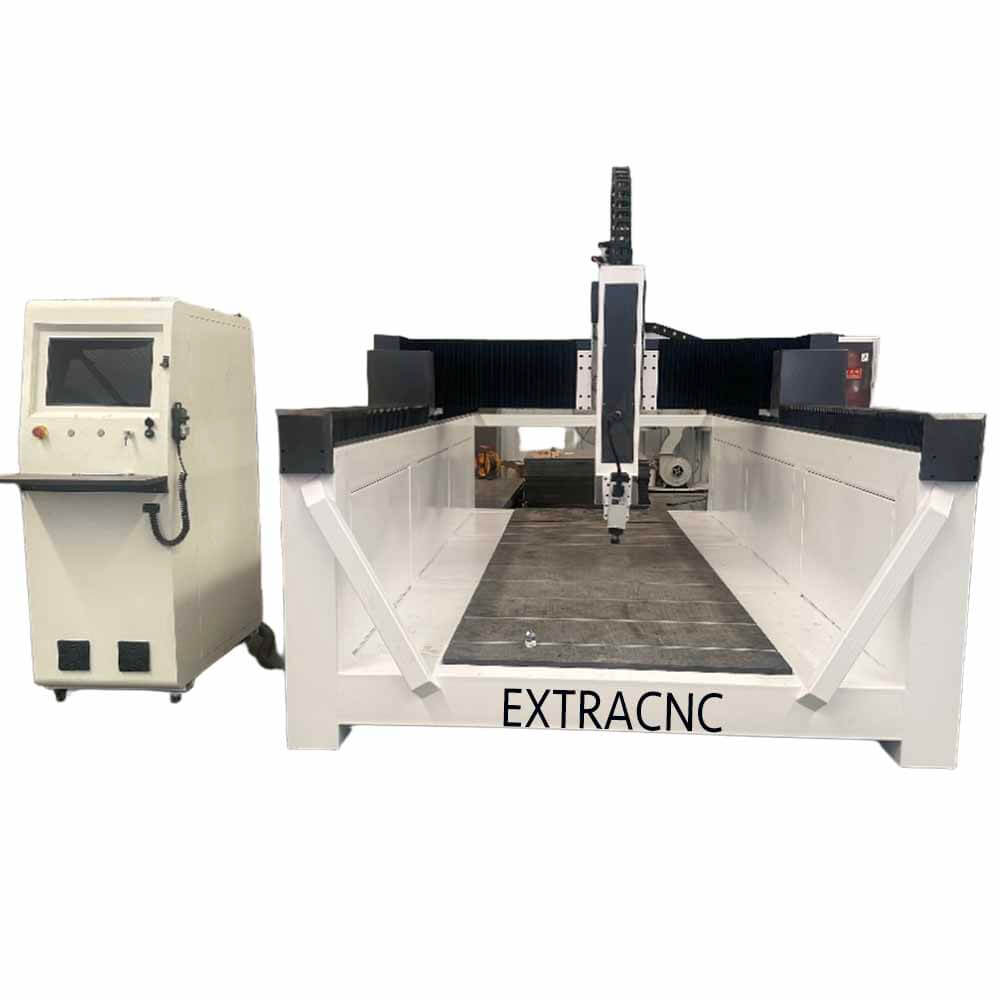

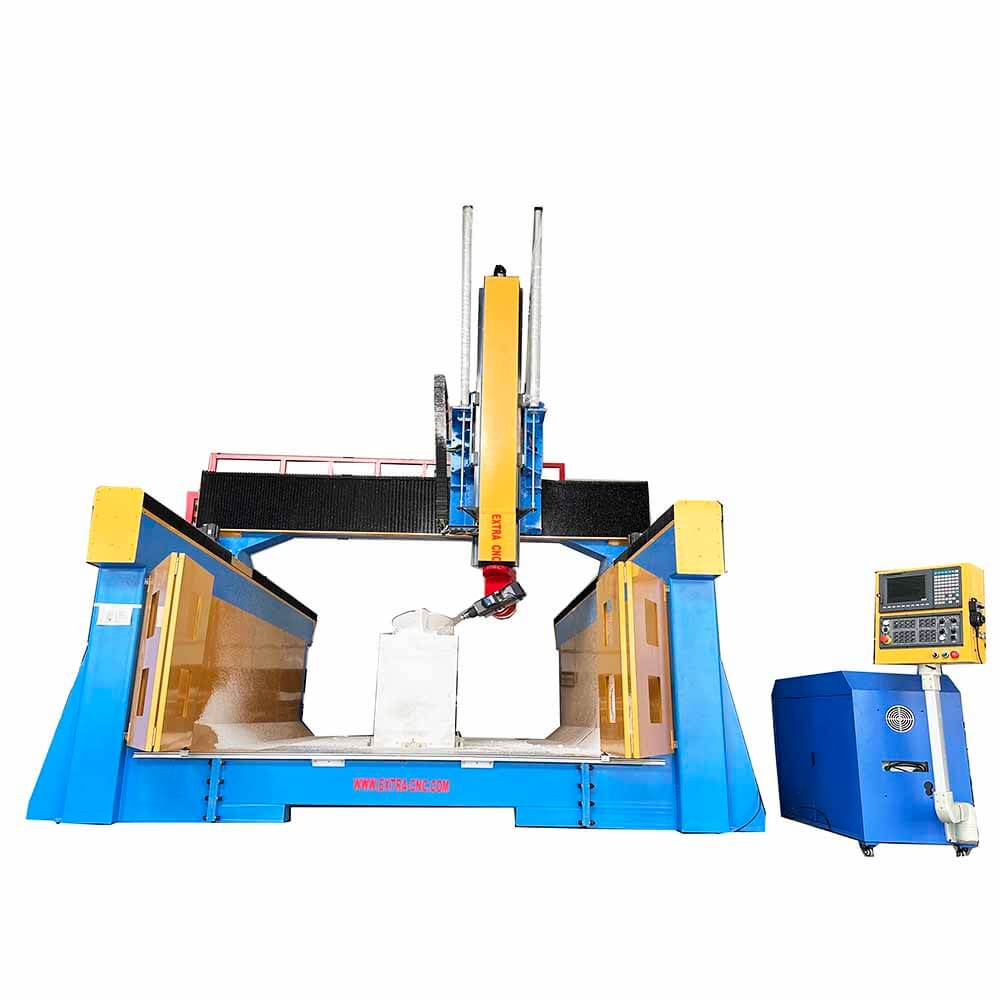

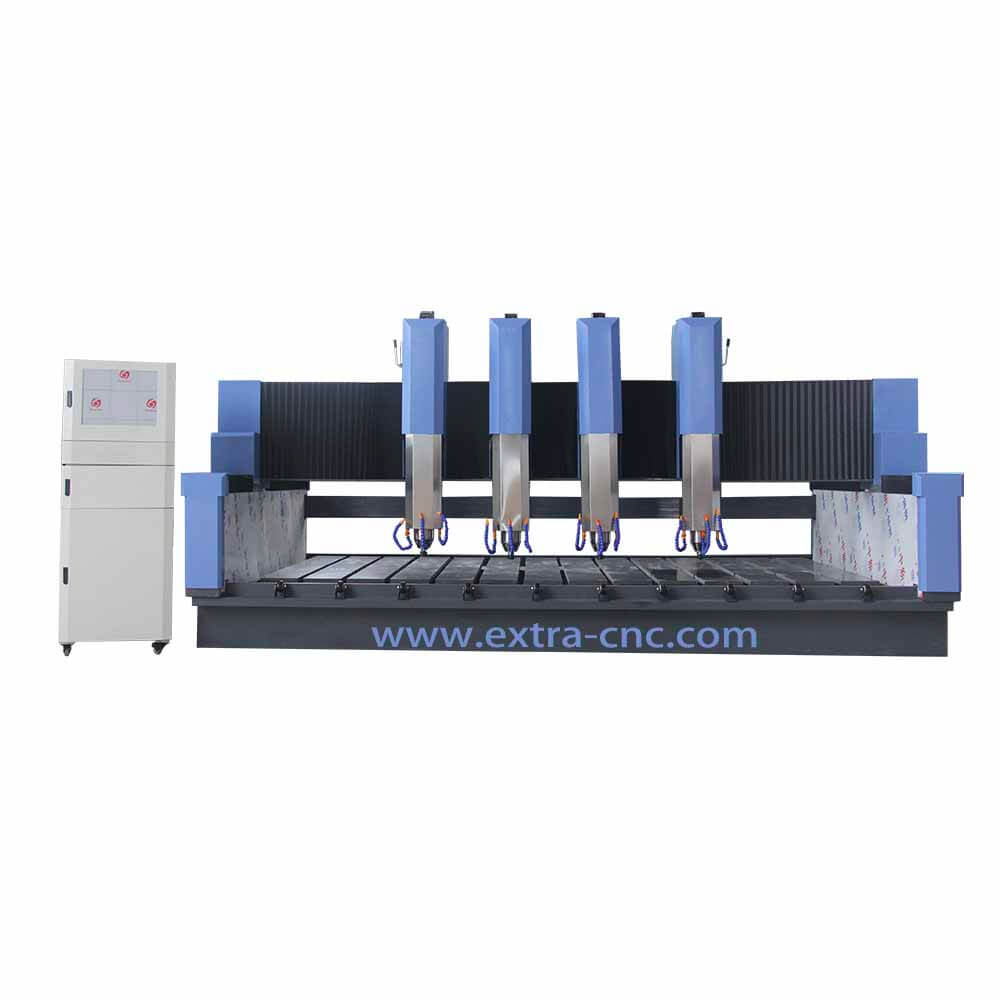

A CNC stone router is an advanced computer-controlled cutting and engraving machine designed for precision processing of hard materials such as marble, granite, quartz, artificial stone, ceramic tiles, jade, glass, blue stone, natural stone, tombstones, headstones, and memorial stones. Engineered for high-performance stone carving and cutting, this stone CNC machine seamlessly integrates with leading CAD/CAM software for smooth design-to-production workflows. Equipped with specialized stone router bits and a dual-direction water or air-cooled tool cooling system, it ensures extended tool life and stable cutting efficiency. The system uses intelligent CNC control with real-time 3D dynamic path simulation to accurately visualize machining operations before production. A CNC stone router excels at detailed stone engraving, surface relief carving, shadow engraving, 3D sculpture carving, letter engraving, line cutting, hollowing, and stone slab cutting — making it a versatile solution for monument making, interior decoration, architectural detailing, garden sculptures, advertising signage, and artistic stonework in both residential and commercial industries.

A multi-head CNC router is a custom-designed computer-controlled machine equipped with multiple spindles or machine heads to meet the needs of high-efficiency, large-scale production in industries like furniture manufacturing and panel processing. These CNC routers boost productivity by allowing simultaneous machining of multiple workpieces, saving time and improving output. Multi-head CNC machines typically come in three types: fully independent heads (each with a separate spindle), single-head models with multiple spindles, and double-head designs with multiple spindles. They are widely used for bulk wood carving, Euro-style furniture making, slatwall panel cutting, and other repetitive woodworking projects.

2025 Guide to Premium CNC Machinery for Scalable Fabrication Solutions | EXTRA CNC

Are you seeking cost-effective CNC equipment to launch a startup or high-performance industrial CNC routers to revolutionize large-scale manufacturing? In 2025, identifying precision CNC machinery tailored to your operational scale is more efficient than ever.

Customizable CNC Solutions for Diverse Production Demands

EXTRA CNC delivers an expansive range of automated fabrication systems engineered to accommodate projects of any dimension. Our standardized models include compact 24″x24″ (2×2 ft), 24″x36″ (2×3 ft), and 24″x48″ (2×4 ft) workhorses, alongside industrial-grade systems such as 48″x48″ (4×4 ft), 48″x96″ (4×8 ft), 60″x120″ (5×10 ft), and 72″x144″ (6×12 ft). Require a bespoke configuration? Our custom-sized CNC router tables are precision-engineered to align with unique manufacturing specifications.

Industry-Leading CNC Technology for Advanced Applications

As a pioneer in automated machining, EXTRA CNC provides professional-grade CNC systems optimized for woodworking, metal fabrication, acrylic processing, signage production, furniture engineering, and bespoke component manufacturing. Catering to craft entrepreneurs, boutique workshops, and Fortune 500 manufacturers alike, our solutions are calibrated to enhance productivity across sectors.

Multi-Axis Machining Systems for Unmatched Precision

Choose from entry-level industrial 3-axis CNC routers to sophisticated multi-axis configurations, including 4-axis rotary engravers, 4-axis oscillating systems (180° capability), and 5-axis CNC machines enabling omnidirectional 3D machining. Whether executing micro-detailed engraving, high-speed cutting, or complex volumetric shaping, EXTRA CNC guarantees micron-level accuracy, robust durability, and ROI-driven performance.

Scalable CNC Investments for Every Enterprise

From budget-conscious starter kits for emerging businesses to aerospace-grade CNC rigs for 24/7 production facilities, EXTRA CNC empowers organizations to select machinery that harmonizes with fiscal constraints and output targets. Our 2025 product lineup integrates intelligent automation, energy-efficient motors, and IoT-enabled controls to minimize downtime and operational costs.

Optimize Your Manufacturing Workflow

Leverage EXTRA CNC’s cutting-edge innovations, including modular tool changers, adaptive cooling systems, and cloud-based G-code optimization. Explore our 2025 collection of automated CNC systems today and consult with our engineering team to identify machinery aligned with your operational objectives.

Why EXTRA CNC?

Precision Engineering: ISO-certified components for sub-0.001″ repeatability

Scalable Configurations: Expandable worktables and spindle upgrades

Industry 4.0 Integration: Compatibility with CAD/CAM software and MES platforms

Lifetime Support: Comprehensive warranties and on-demand technical assistance

Transform your fabrication capabilities with EXTRA CNC—where innovation meets industrial reliability. Discover smart manufacturing investments that maximize throughput and minimize waste in 2025.