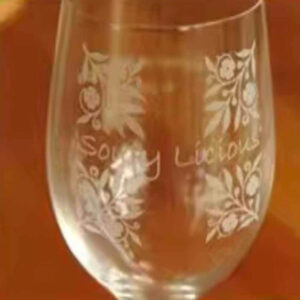

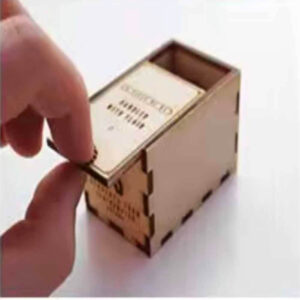

The laser cutting and engraving machine is suitable for a wide range of materials, including wood, paper, leather, fabric, acrylic, plexiglass, resin, wool, plastic, rubber, ceramic, crystal, bamboo, marble, granite, tiles, Delrin, double-color board, painted metals, anodized aluminum, EVA, and more. It serves various industries such as advertising, furniture and interior design, musical instrument manufacturing, custom gifts and crafts, leather apparel production, architectural modeling, packaging and printing, and totem creation, making it a versatile solution for multiple applications.