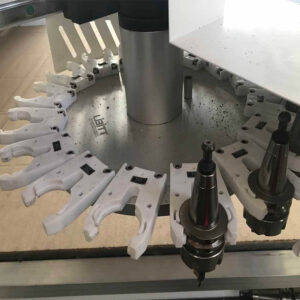

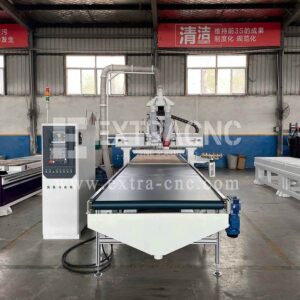

Perfect for woodworking factories, furniture makers, and cabinetry shops, this machine is ideal for cutting, carving, drilling, and engraving various wood panels with high efficiency. Widely used for producing cabinets, doors, wardrobes, and customized wood products, it’s a smart choice for those seeking the best CNC router with ATC, especially in 1325 ATC CNC router factories.