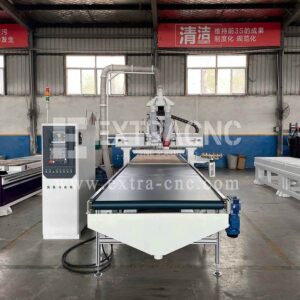

Ideal for producing kitchen cabinet doors, wardrobe doors, and decorative wood panels, this ATC CNC router machine cuts, engraves, drills, and grooves MDF, plywood, and solid wood with high precision and efficiency. It’s widely used in furniture factories and woodworking shops looking for reliable 2030 ATC CNC routers, 2040 ATC CNC routers, and 5x10ft ATC CNC router machines to boost production quality and speed.