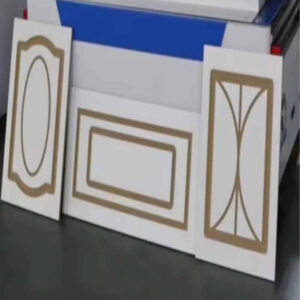

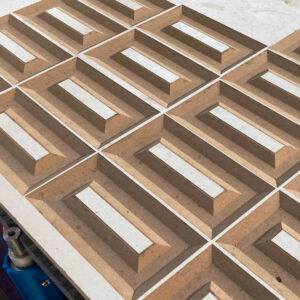

The High Quality Multifunctional CNC Router is ideal for a wide range of woodworking applications, including cutting and nesting wood panels for cabinets and furniture, carving intricate 3D designs on wooden doors, and producing decorative wall panels and signage. With its automatic tool changer, optional labeling system, and auto loading/unloading features, this CNC router is perfectly suited for factories and workshops seeking to improve efficiency, precision, and automation in large-scale or customized production.