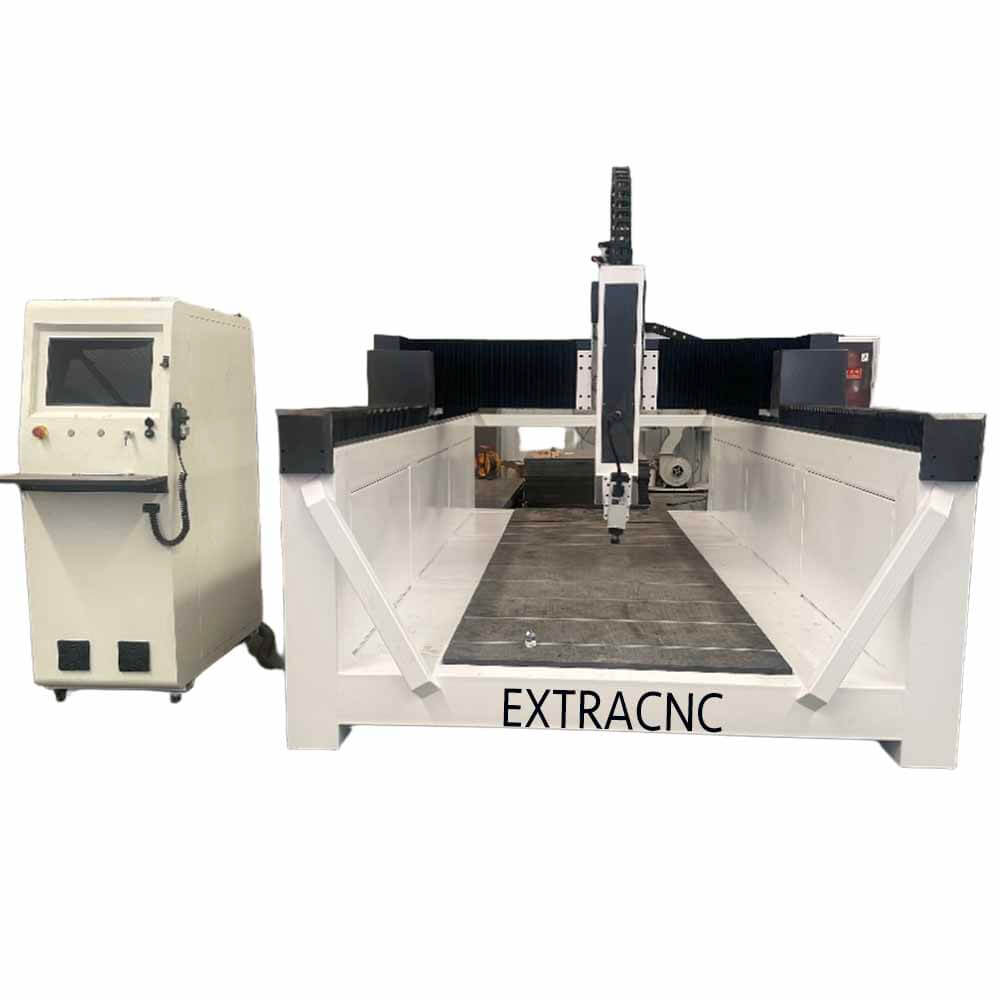

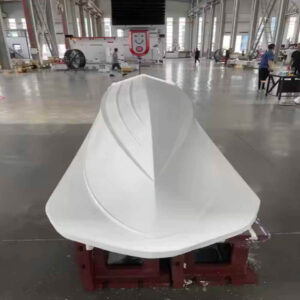

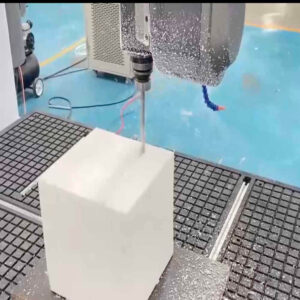

The 4 Axis CNC Milling Machine is ideal for precision foam mold making in industries such as aerospace, automotive, packaging, and prototyping. It efficiently mills complex 3D shapes in materials like EVA, PU, and EPS foam, enabling fast, accurate production of high-quality molds for casting, tooling, and design prototypes.