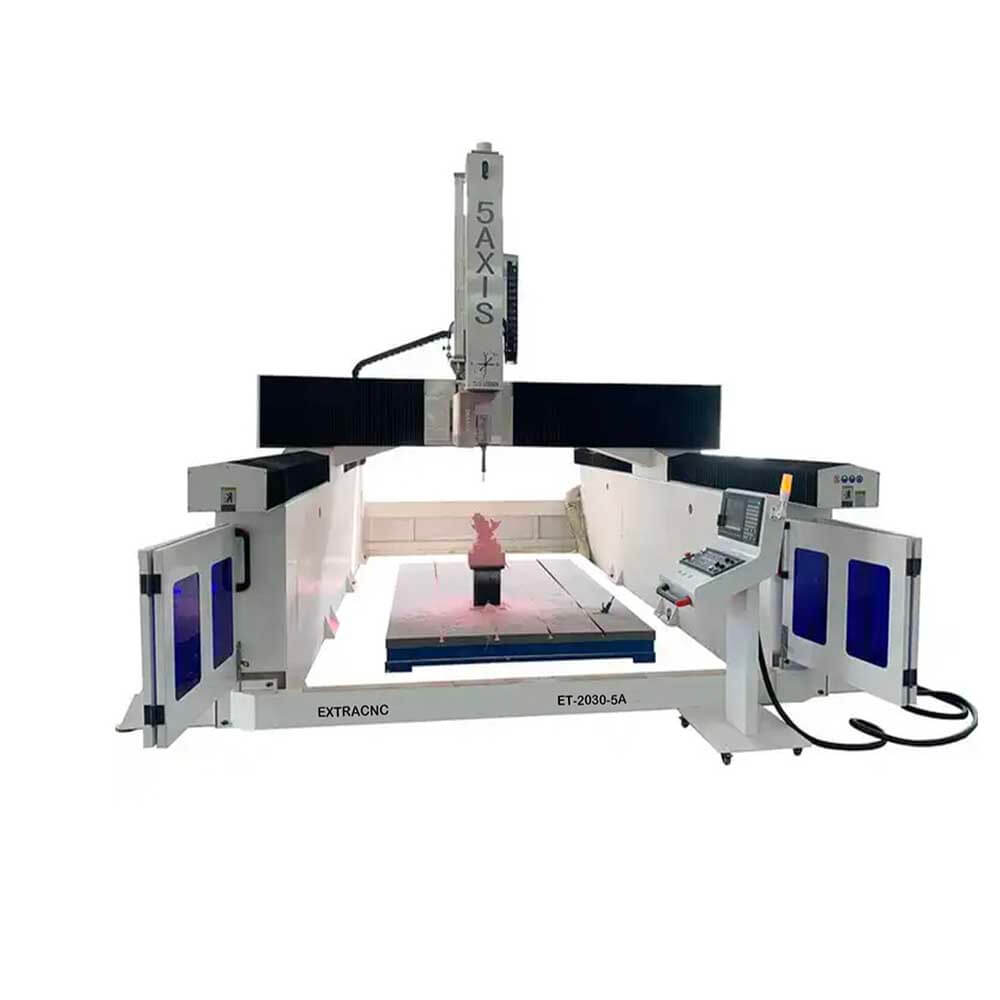

The ExtraCNC® 5 Axis CNC Router is engineered for high-precision cutting, milling, and sculpting across a wide range of materials. Whether you’re working in industrial manufacturing, woodworking, foam carving, or prototyping, this machine delivers the performance and versatility you need.

Supported Materials:

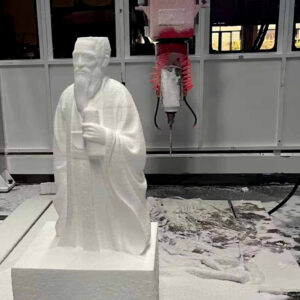

High-Density Foam – Perfect for creating large-scale props, 3D sculptures, and molds with exceptional accuracy.

Wood (All Types) – Handles softwood, hardwood, MDF, and plywood for cabinetry, furniture, and decorative woodwork.

Plastics and Veneers – Suitable for machining acrylic, PVC, composite panels, and laminated sheets.

Non-Ferrous Metals – Cuts aluminum, brass, copper, and similar materials (requires an external cooling system for optimal performance).

Applications of the ExtraCNC® 5 Axis CNC Router

With full 5-axis capability and tool center point programming, the ExtraCNC® 5 Axis excels in industries that demand complex machining and flawless finish quality.

Ideal for Applications Such As:

Cabinet Making – Precision routing and shaping for cabinet doors, drawers, and panels.

Foam Sculpting & Theming – Carve intricate shapes for signs, props, and themed environments.

Prototyping & Product Design – Rapid prototyping for mechanical parts, consumer goods, and concept models.

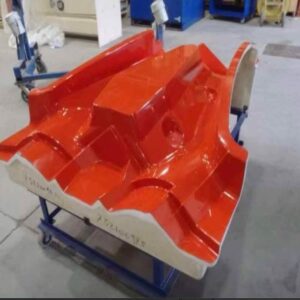

Mold Making – Create detailed molds from foam, wood, or plastic for casting and manufacturing.

Sign Making – Produce 3D letters, logos, and layered signage from various materials.

Composite Material Fabrication – Ideal for cutting and finishing composite parts in the aerospace, marine, and automotive sectors.